A miniature intermittent pump for lubricating bearings of hydrodynamic fan cooling towers and its installation and working methods

A technology of bearing lubrication and hydrodynamic fan, which is applied to components of pumping devices for elastic fluids, engine components, machines/engines, etc., can solve problems such as complex transmission methods, difficult equipment maintenance, and low safety and reliability. Achieve the effects of simple transmission relationship, broad application prospects and promotion value, and strong safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

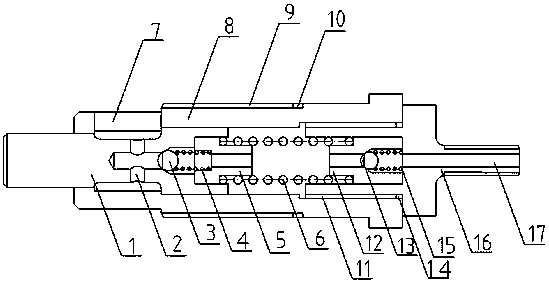

[0036]In this embodiment, a miniature intermittent pump used for lubricating bearings of a cooling tower of a hydrodynamic fan has dimensions of the entire miniature plunger pump, with a total length of 154.25 mm, a maximum radius of 25.00 mm, and a minimum radius of 16 mm. The cam is set by the external driving part. The cam adopts a semicircle and semiellipse design, and is driven by constant angular velocity rotation with a period of 0.5s. Before the work starts, the entire miniature intermittent pump is placed in the oil tank, the inside of the pump casing II is filled with lubricating oil (grease), and the pressure of the lubricating oil (grease) inside and outside the pump casing is set to 10kpa. The elastic coefficients of the oil inlet spring, oil outlet spring and plunger recovery spring are set to 201N / m.

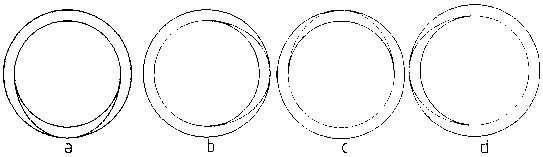

[0037] The cam adopts a semicircle and semiellipse design and rotates at a constant angular velocity. In the semi-elliptical area, when rotating from position a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com