Device for measuring gravitational acceleration in rotating state and method for measuring and extracting gravitational acceleration in rotating state

A technology of gravitational acceleration and gravitational accelerometer, which is applied in the field of gravitational acceleration measurement devices in a rotating state, can solve the problems of measurement accuracy gap, large torque, and difficulty in meeting the requirements of the intermittent measurement mode when drilling is stopped, and achieves flexible installation methods and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

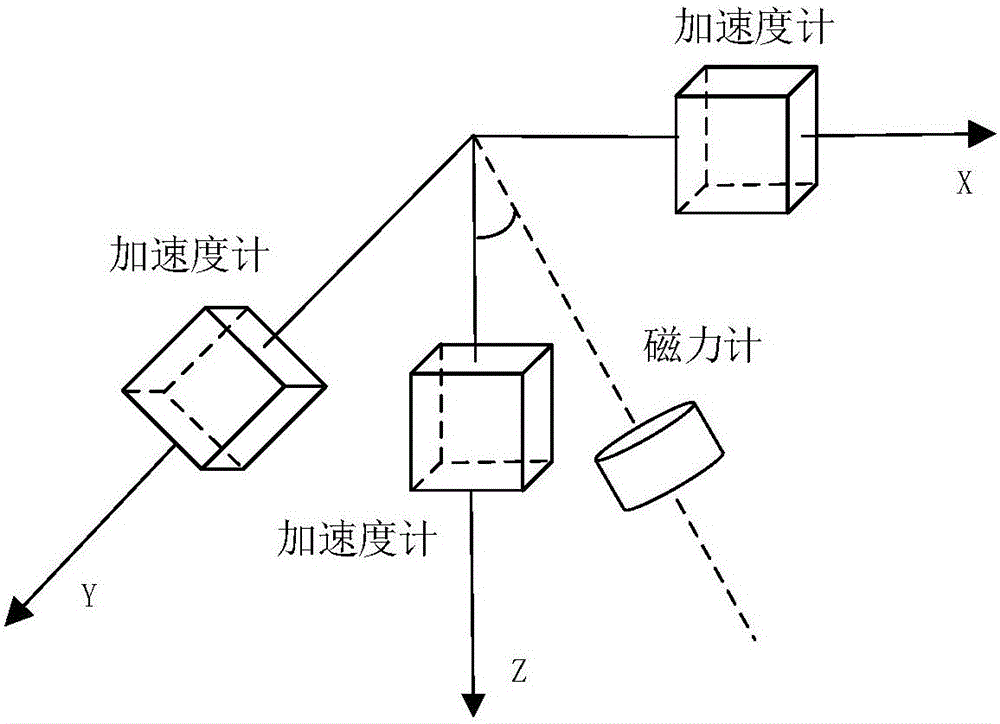

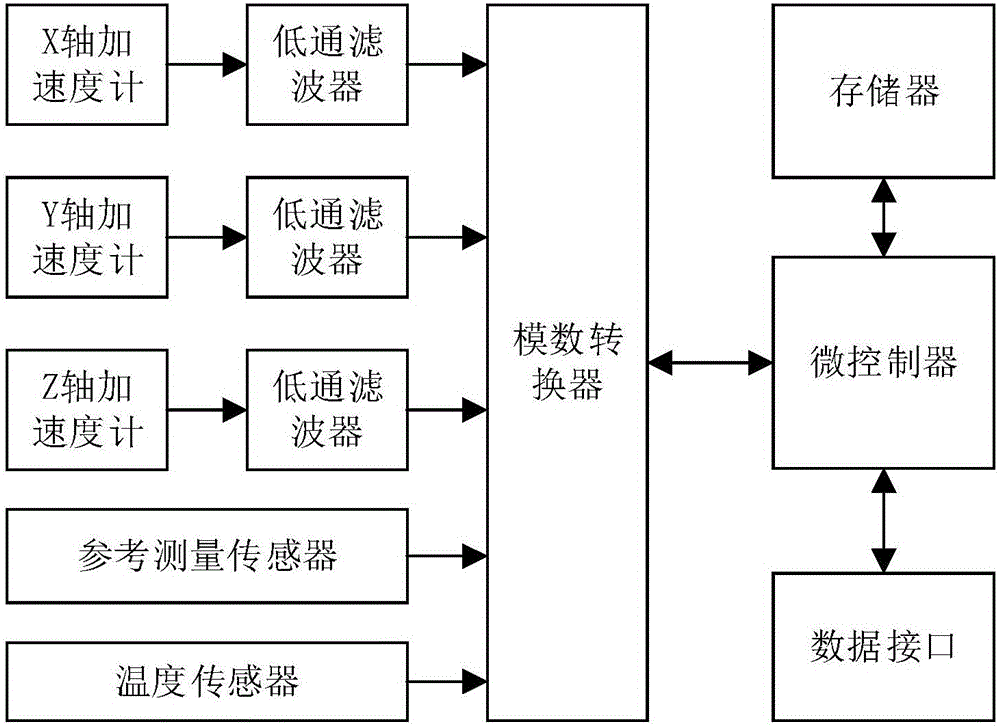

[0033] A device for measuring the acceleration of gravity in a rotating state, including a sensor and a measurement circuit, the sensor includes a three-axis gravity accelerometer, a reference measurement sensor and a temperature sensor, the three-axis gravity accelerometer is connected with a low-pass filter, and the sensitive axis of the reference measurement sensor The angle to the axis of rotation depends on the type of sensor so that the reference measurement sensor can produce periodic changes in the direction of the sensitive axis as the drill tool rotates. The three-axis gravitational accelerometer is installed orthogonally, the Z-axis is along the axial direction of the drilling tool, and the X and Y are along the radial direction of the drilling tool. The temperature sensor is installed next to the three-axis gravity accelerometer, and the magnetometer is used as a reference measurement sensor. The sensitive axis of the magnetometer is parallel to the X axis. The inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com