Corrugated waterproof heat-insulation integrated plate, processing technique and construction method

An integrated board and waterproof board technology, which is applied to tools for roof engineering, roofs using flat/curved panels, roof coverings, etc. effect, reduce material cost, reduce the effect of laying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

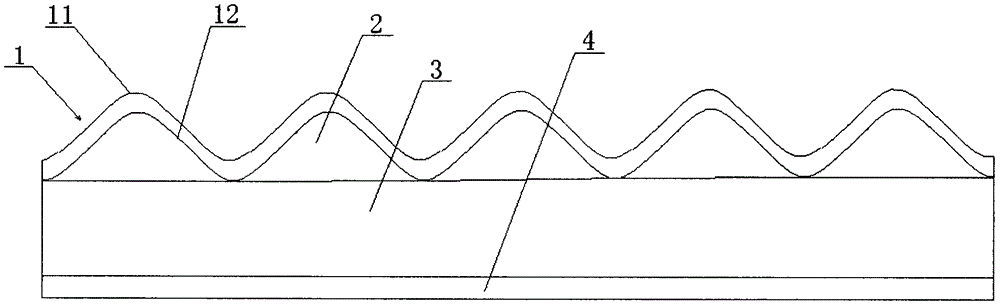

[0017] like figure 1 As shown, a corrugated waterproof and thermal insulation integrated board provided by the present invention includes a corrugated waterproof board 1, and the corrugated waterproof board 1 includes a surface layer 11 and a bottom layer 12. The grooves and ridges of the surface layer 11 correspond to the ridges of the bottom layer, the ridges of the surface layer 11 correspond to the grooves of the bottom layer, and the grooves of the bottom layer 12 are filled with the polyurethane filling layer 2 supporting the corrugated waterproof board 1 , the bottom surface of the polyurethane filling layer 2 is bonded with an insulating layer 3 . The insulation layer 3 is made of polyurethane material, and the insulation layer 3 and the polyurethane filling layer 2 are integrally made, which is convenie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com