Sleeve sterilization agent and preparation method thereof

A sterilant and sleeve technology, which is applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of high cost, poor detergency, and peculiar smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

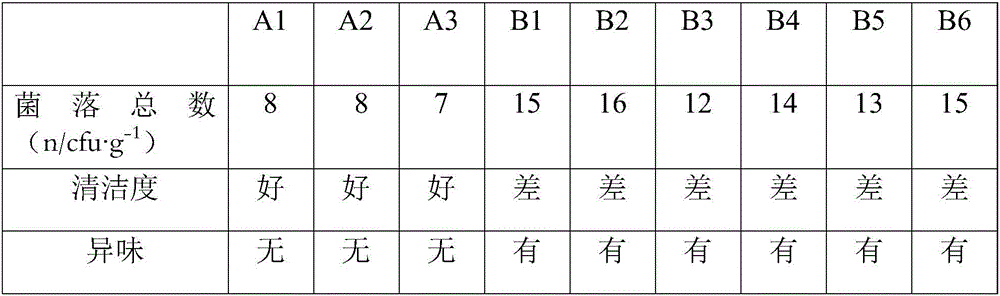

Examples

Embodiment 1

[0018] In parts by weight, first mix 100 parts of water, 20 parts of sodium lauryl sulfate, 5 parts of ethyl acetate, 3.5 parts of propyl acetate, 1 part of propylene oxide, 5 parts of fatty amides and 1.5 parts of phosphomolybdic acid, and Heating at 42°C for 20 minutes; then adding 2 parts of aluminum hydroxide with a concentration of 0.05 mol / L to adjust the pH to 5.5 to prepare the composition; finally adding 3.5 parts of methylcellulose to adjust the viscosity of the composition to 7000mpas, and at 500rpm Stir and mix for 10 minutes at the speed of rotation to prepare the cannula sterilizer A1.

Embodiment 2

[0020] In parts by weight, first mix 140 parts of water, 20 parts of sodium lauryl sulfate, 9.5 parts of ethyl acetate, 7.5 parts of propyl acetate, 5 parts of propylene oxide, 15 parts of fatty acid amide and 4 parts of trichlorohydroxy diphenyl ether Mix and heat at 48° C. for 0 min; then add 7 parts of aluminum hydroxide with a concentration of 0.1 mol / L to adjust the pH to 6.5 to prepare a composition; finally add 5.5 parts of sodium carboxymethylcellulose to adjust the viscosity of the composition to 9000mpas, and stirred and mixed at a speed of 600rpm for 20min to prepare the cannula sterilizer A2.

Embodiment 3

[0022] In parts by weight, first 120 parts of water, 20 parts of sodium lauryl sulfate, 7 parts of ethyl acetate, 5 parts of propyl acetate, 3 parts of propylene oxide, 10 parts of fatty amides and 3 parts of phosphomolybdic acid were mixed, and Heating at 45°C for 25 minutes; then adding 4 parts of aluminum hydroxide with a concentration of 0.075mol / L to adjust the pH to 6 to prepare the composition; finally adding 4.5 parts of polyacrylamide to adjust the viscosity of the composition to 8000mpas, and at 550rpm Stir and mix at a rotating speed for 15 minutes to prepare cannula sterilizer A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com