Production method of coal-series fuel oil

A production method and fuel oil technology, applied in the field of coal chemical industry, can solve the problems of low energy utilization rate, uneven composition, complex process, etc., achieve good environmental protection effect, reduce the content of impurities such as nitrogen and sulfur, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

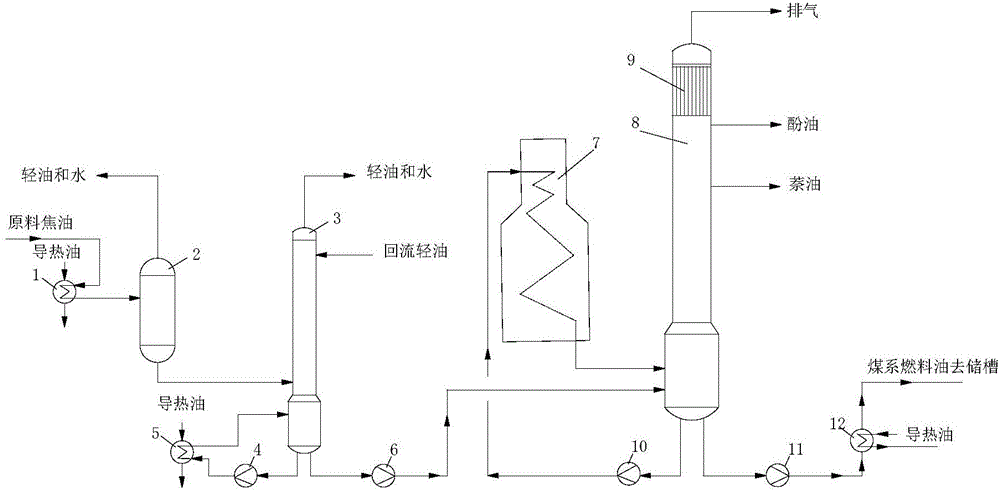

[0038] A specific embodiment of the production method of coal-based fuel oil, the specific steps are as follows:

[0039] 1) filling the dehydration tower 3 through the tar preheater 1 through the pre-dehydration tower 2, and filling the dehydration tower 3 to a certain liquid level;

[0040]2) When the liquid level of the dehydration tower 3 is close to 50%, start the circulation pump 4 at the bottom of the dehydration tower to start the circulation of the dehydration tower;

[0041] 3) Start the heat transfer oil system, start heating the heat transfer oil, and the heat transfer oil starts to feed the tar preheater 1 and the dehydration tower reboiler 5 (heat the pre-dehydration tower through the tar preheater, and dehydrate the dehydration tower through the dehydration tower reboiler) Tower 3 heating) heat supply;

[0042] 4) Start the extraction pump 6 at the bottom of the dehydration tower to supply the tar raw material to the distillation tower 8; start the extraction p...

Embodiment 2

[0050] A specific embodiment of the production method of coal-based fuel oil, the specific steps are as follows:

[0051] 1) filling the dehydration tower 3 through the tar preheater 1 through the pre-dehydration tower 2, and filling the dehydration tower 3 to a certain liquid level;

[0052] 2) When the liquid level of the dehydration tower 3 is close to 50%, start the circulation pump 4 at the bottom of the dehydration tower to start the circulation of the dehydration tower;

[0053] 3) Start the heat transfer oil system, start heating the heat transfer oil, and the heat transfer oil starts to feed the tar preheater 1 and the dehydration tower reboiler 5 (heat the pre-dehydration tower through the tar preheater, and dehydrate the dehydration tower through the dehydration tower reboiler) Tower 3 heating) heat supply;

[0054] 4) Start the extraction pump 6 at the bottom of the dehydration tower to supply the tar raw material to the distillation tower 8; start the extraction ...

Embodiment 3

[0062] A specific embodiment of the production method of coal-based fuel oil, the specific steps are as follows:

[0063] 1) filling the dehydration tower 3 through the tar preheater 1 through the pre-dehydration tower 2, and filling the dehydration tower 3 to a certain liquid level;

[0064] 2) When the liquid level of the dehydration tower 3 is close to 50%, start the circulation pump 4 at the bottom of the dehydration tower to start the circulation of the dehydration tower;

[0065] 3) Start the heat transfer oil system, start heating the heat transfer oil, and the heat transfer oil starts to feed the tar preheater 1 and the dehydration tower reboiler 5 (heat the pre-dehydration tower through the tar preheater, and dehydrate the dehydration tower through the dehydration tower reboiler) Tower 3 heating) heat supply;

[0066] 4) Start the extraction pump 6 at the bottom of the dehydration tower to supply the tar raw material to the distillation tower 8; start the extraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com