Automatic window film waste edge recycling device

An automatic recycling and window film technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of unfavorable processing efficiency, large number of workers, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

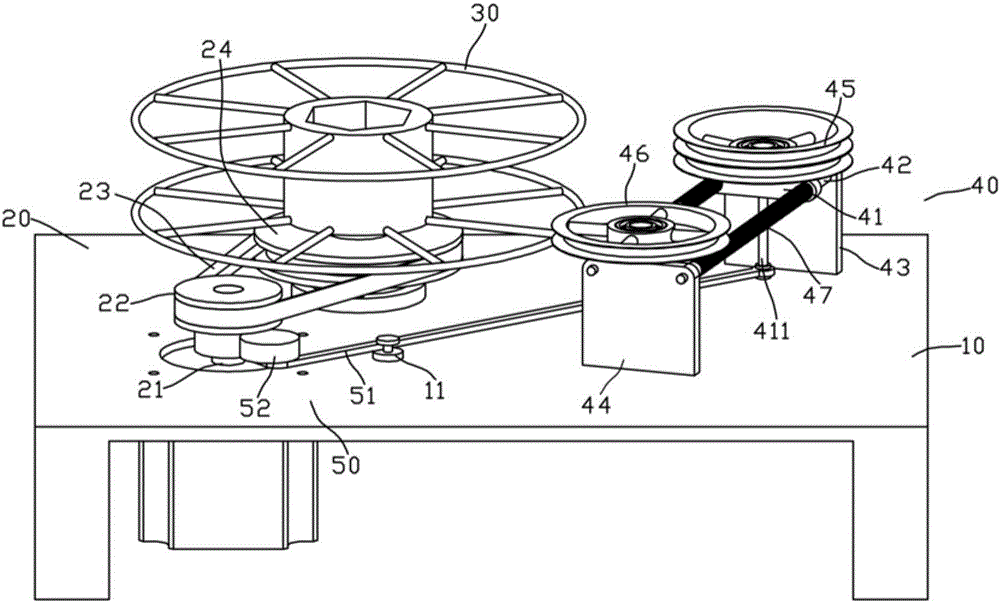

[0019] Examples, see e.g. Figure 1 to Figure 2 As shown, a window film waste edge automatic recycling device includes a bracket 10, a rotating assembly 20 is installed on the top of the bracket 10, the top of the rotating assembly 20 is fixed with a recovery disc 30 by bolts, and the rotating assembly 20 can be Drive the recovery disc 30 to rotate; the side of the recovery disc 30 is provided with a guide device 40 , and a speed regulating mechanism 50 is provided between the guide device 40 and the transmission assembly 20 .

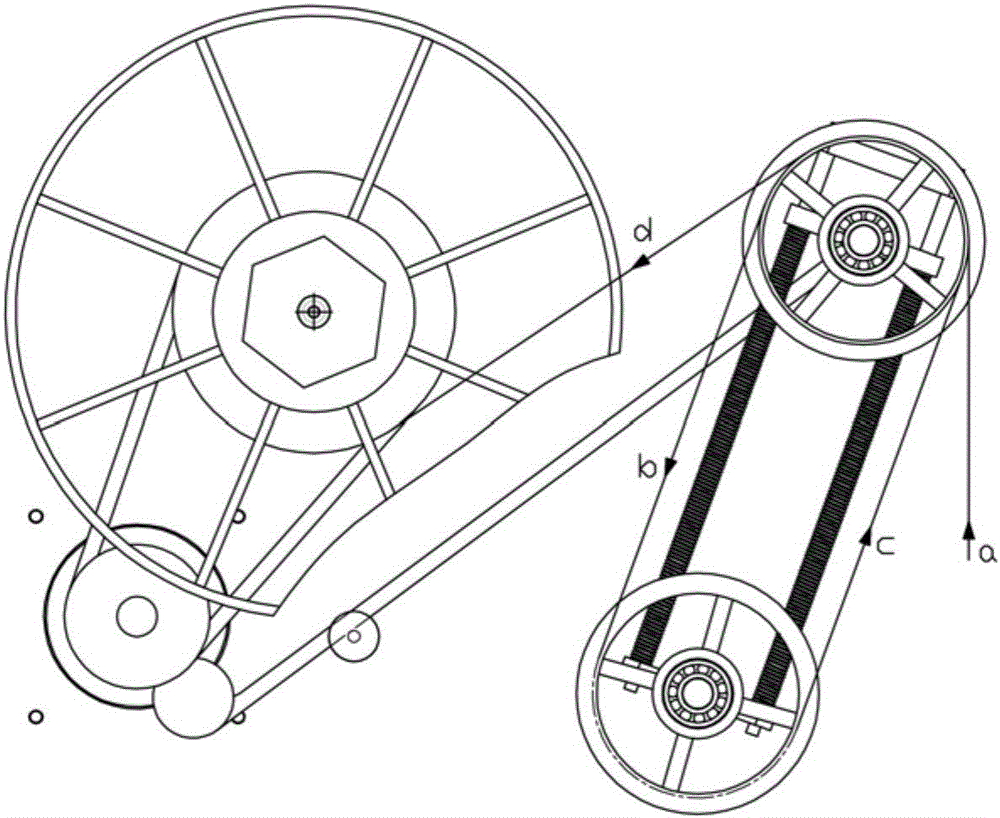

[0020] Furthermore, the rotating assembly 20 includes a motor 21, and the motor 21 is fixed below the bracket 10; the output shaft of the motor 21 is connected to a small pulley 22, and the small pulley 22 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com