Assembly tooling for tubular belt conveyor and method for assembling conveyor using the tooling

A tubular belt type and tooling technology, which is used in transportation and packaging, coiling strips, thin material processing, etc., can solve the problem that the installation requirements of the pipe belt machine cannot be met, the connection process between the tape and the rotating shaft is difficult, and the unwinding tooling structure is rough and simple. and other problems, to achieve the effect of saving installation and disassembly time, easy speed regulation, and stable rotation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the embodiments, and the described embodiments are only a part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, other used embodiments obtained by persons of ordinary skill in the art without creative efforts all belong to the protection scope of the present invention.

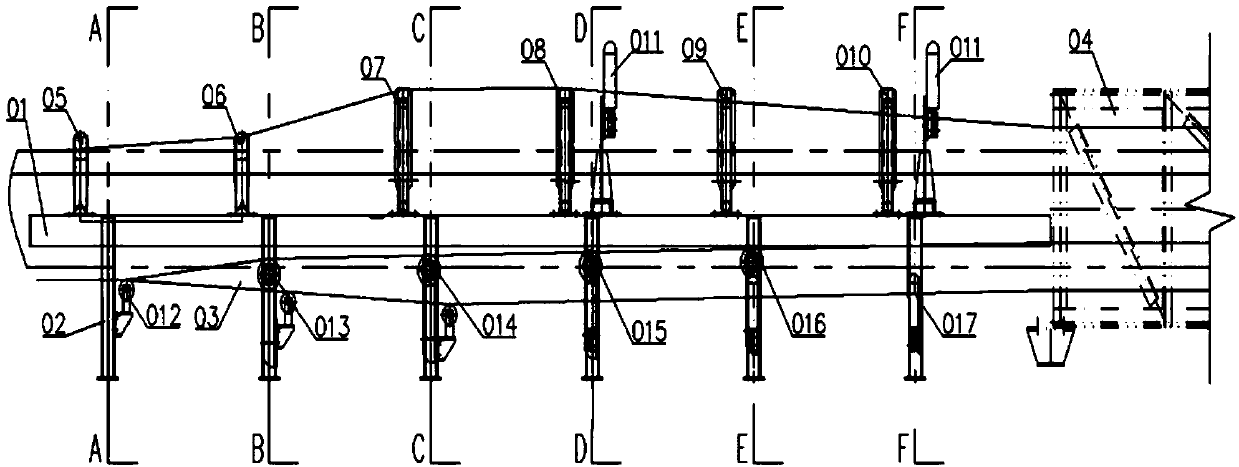

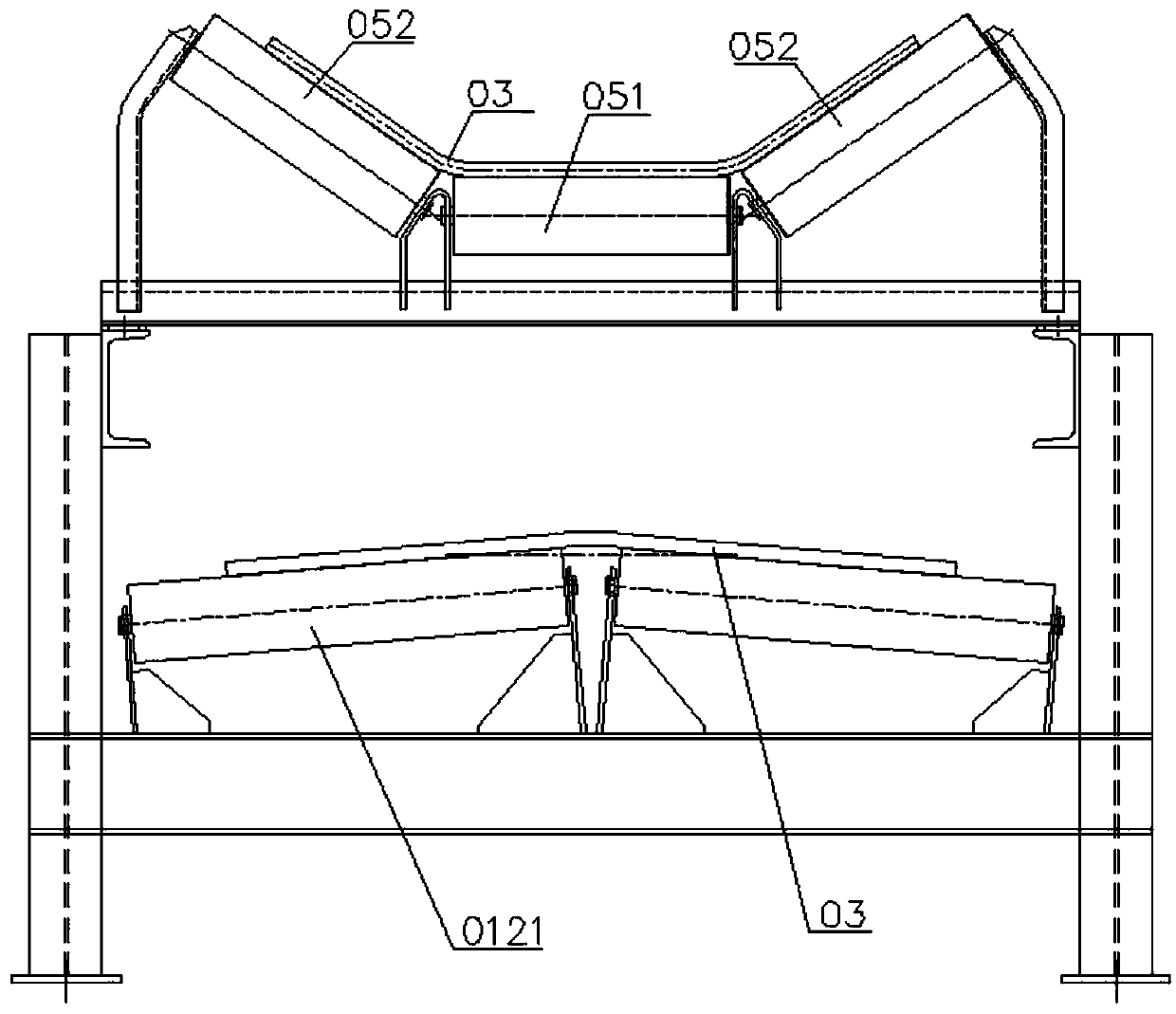

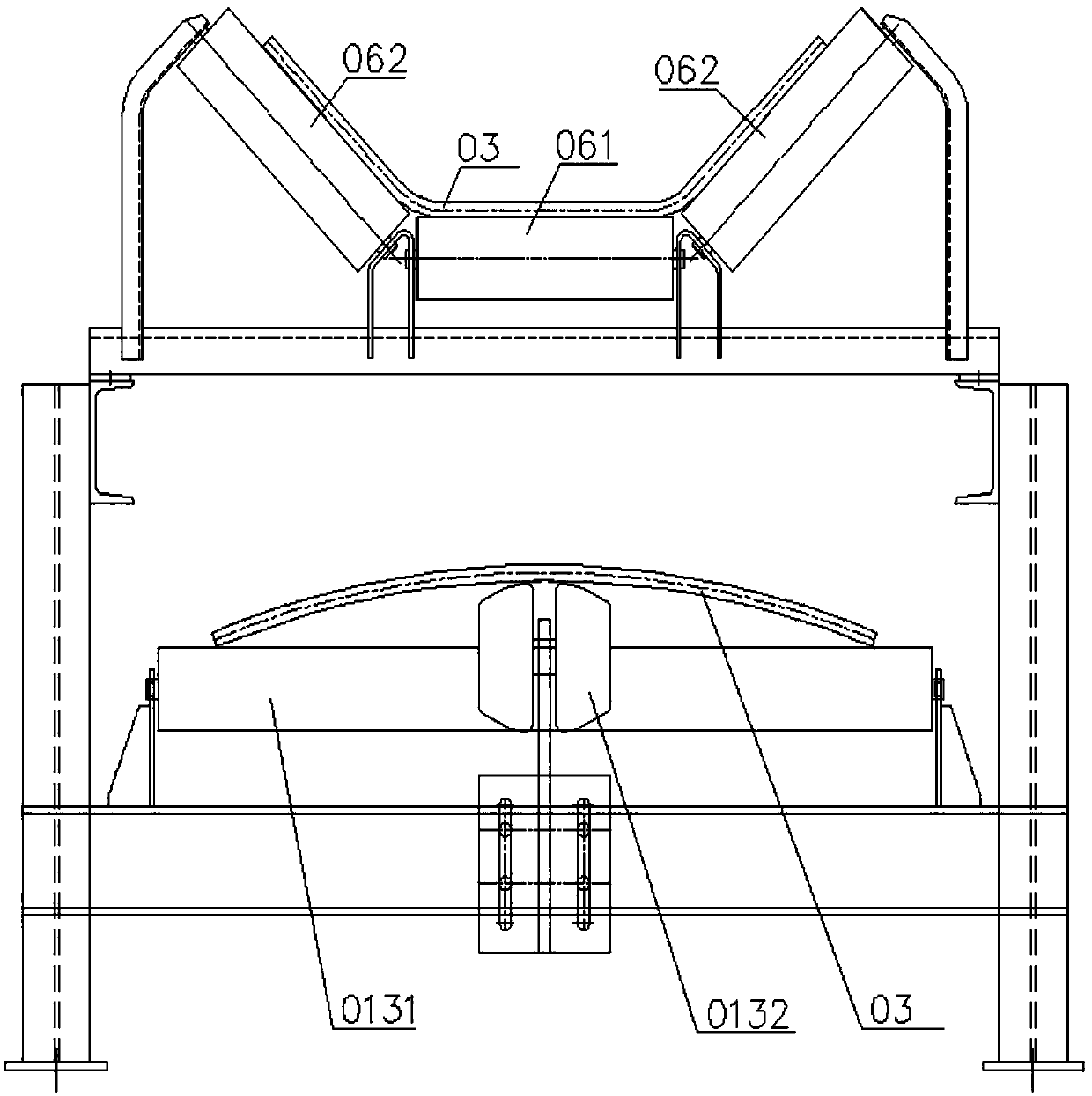

[0052] combined with figure 1 , the tubular belt conveyor assembly tooling of the present invention includes unwinding tooling and multi-working condition belt unwinding tooling, the multi-working condition belt unwinding tooling includes a middle bracket 01, and the middle bracket 01 is installed on the ground through a plurality of legs 02 Above, each leg 02 is connected to the embedded parts on the ground foundation through anchor bolts. Below the middle bracket 01 is provided an adjustment device for gradually adjusting the adhesive tape from an unfolded state to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com