Self-unloading type logistics warehouse

A self-unloading, warehouse technology, applied in the directions of loading/unloading, transportation and packaging, can solve the problems of rapid cooling and cooling of difficult inner storage materials, slow detection of defects, and large land occupation, achieving compact and simplified structure and saving drive. Motor, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0035] Figure 1 to Figure 19 One specific embodiment of the invention is shown.

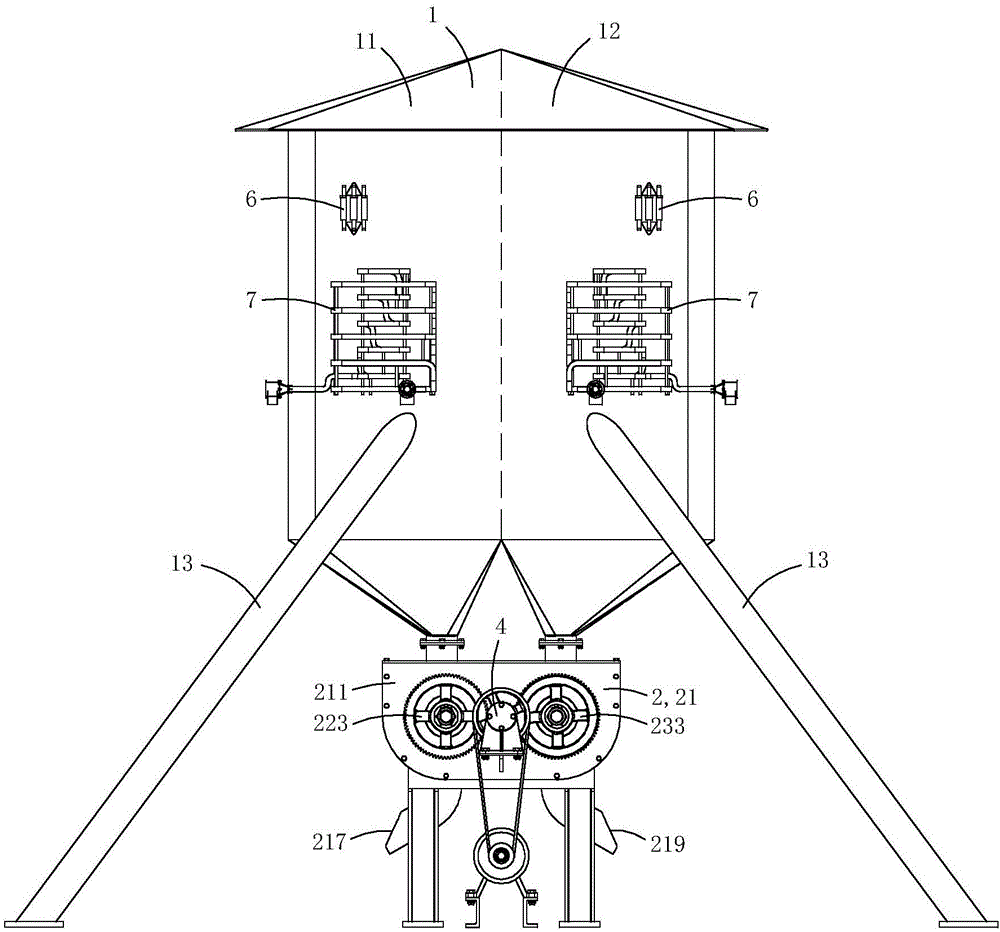

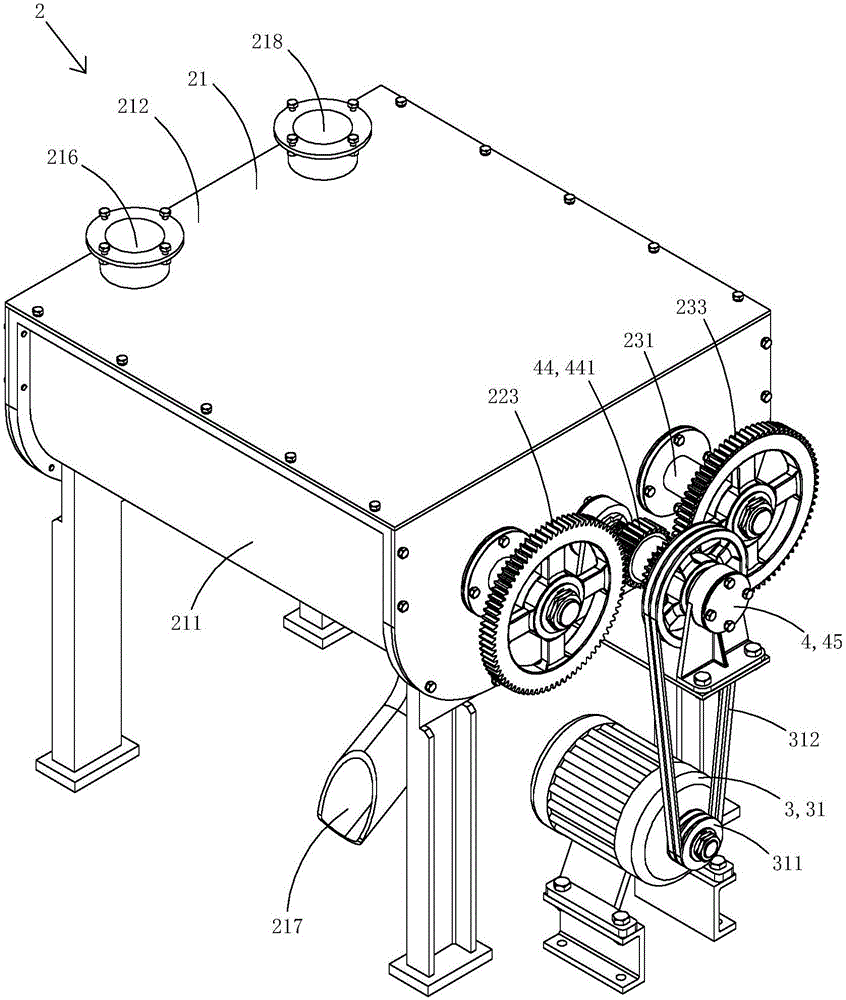

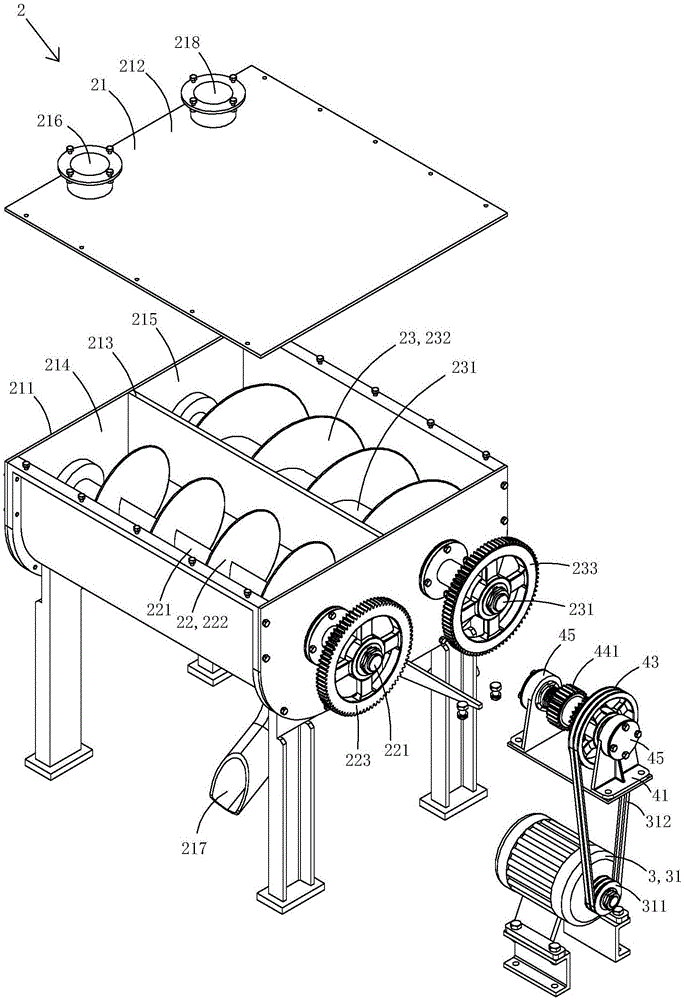

[0036] Present embodiment is a kind of self-unloading logistics warehouse, see Figure 1 to Figure 10 As shown, it includes a double-body warehouse 1 and a discharge device 2 arranged under the double-body warehouse.

[0037] The double-body warehouse 1 has a first warehouse 11 and a second warehouse 12 arranged side by side. The bottom of the first warehouse is conical, and the center of the bottom has a first outlet; the bottom of the second warehouse is also conical, and the bottom of the second warehouse is conical. There is a second outlet in the center. In this embodiment, four supporting pillars 13 are arranged at the lower part of the double-body warehouse, and the double-body warehouse stands on the ground through the four supporting pillars. In practice, it is also possible not to support the pillars, but directly fix the double-body warehouse on the wall or on the carrier, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com