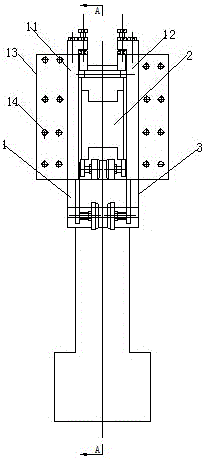

Tread winding machine rolling mechanism

A winding machine and rolling technology, applied in the field of the rolling mechanism of the tread winding machine, can solve the problems of low bonding density, uneven bonding thickness, easy occurrence of air bubbles and delamination in the tire, etc., so as to reduce the amount of air bubbles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

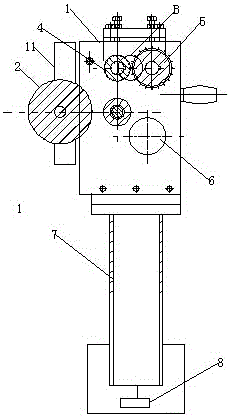

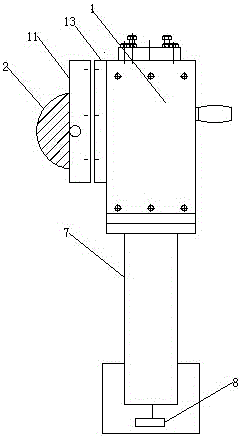

Embodiment 2

[0025] This embodiment is further improved on the basis of embodiment 1, and the axial cross-sectional shape of the main pressing roller 2 is "H". The mounting through holes 14 on the mounting board 13 are arranged in rows and at least one row is arranged. The diameter of the front pressing roller 4 is smaller than the diameter of the rear pressing roller 5. The film winding and rolling mechanism further includes a vertical arm 7, the upper end of the vertical arm 7 is connected to the lower end of the first frame plate 1 and the lower end of the second frame plate 3, the lower end of the vertical arm 7 is connected with a driver 8, the driver 8 Drive the vertical arm to move up and down. A motor 6 is also arranged between the first frame plate 1 and the second frame plate 3, and the motor 6 drives the main pressing roller 2, the front pressing roller 4 and the rear pressing roller 5 to move respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com