Porcelain sleeve assembling tool

A technology for assembling tools and porcelain sleeves, which is applied in the field of tooling manufacturing, can solve the problems that the porcelain sleeves cannot be compacted, the gap between the porcelain sleeves is large, and the working efficiency is low, so as to reduce air exposure and oxidation, shorten the assembly operation time, and reduce the assembly time. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

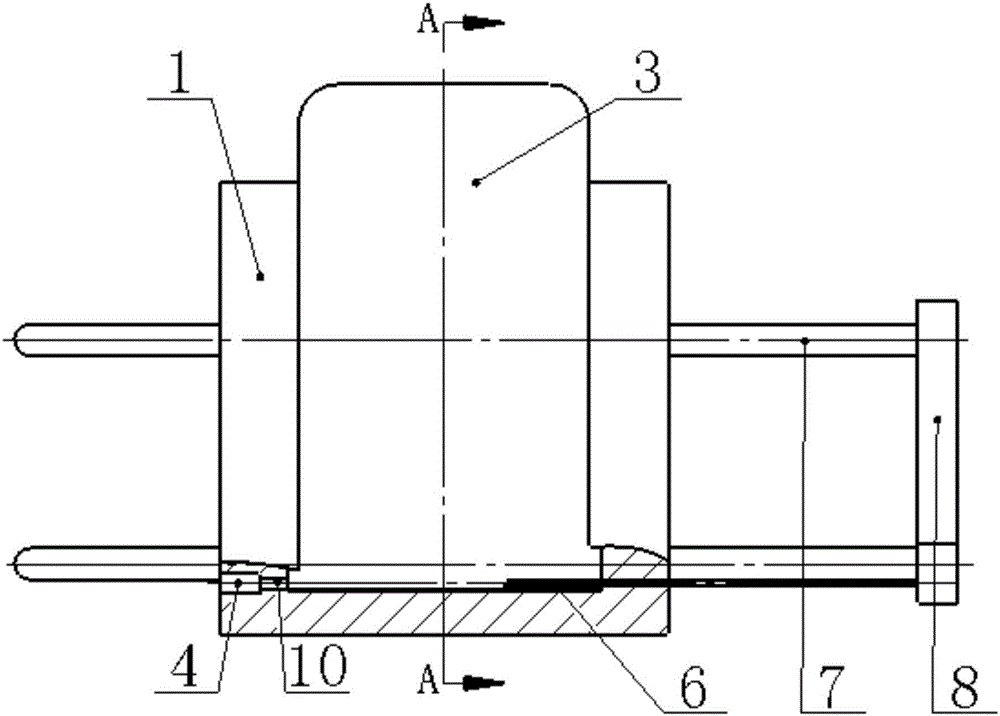

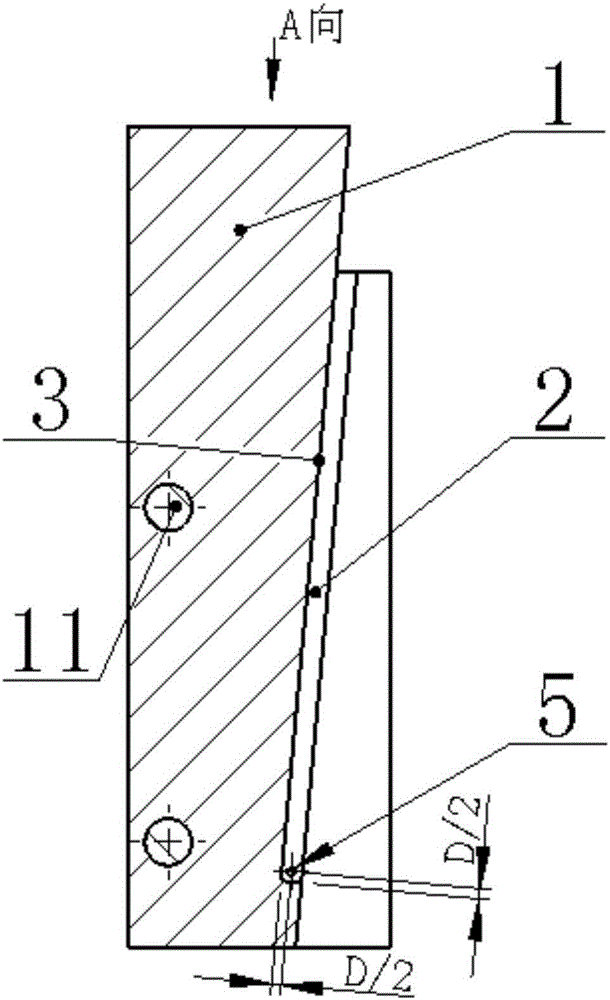

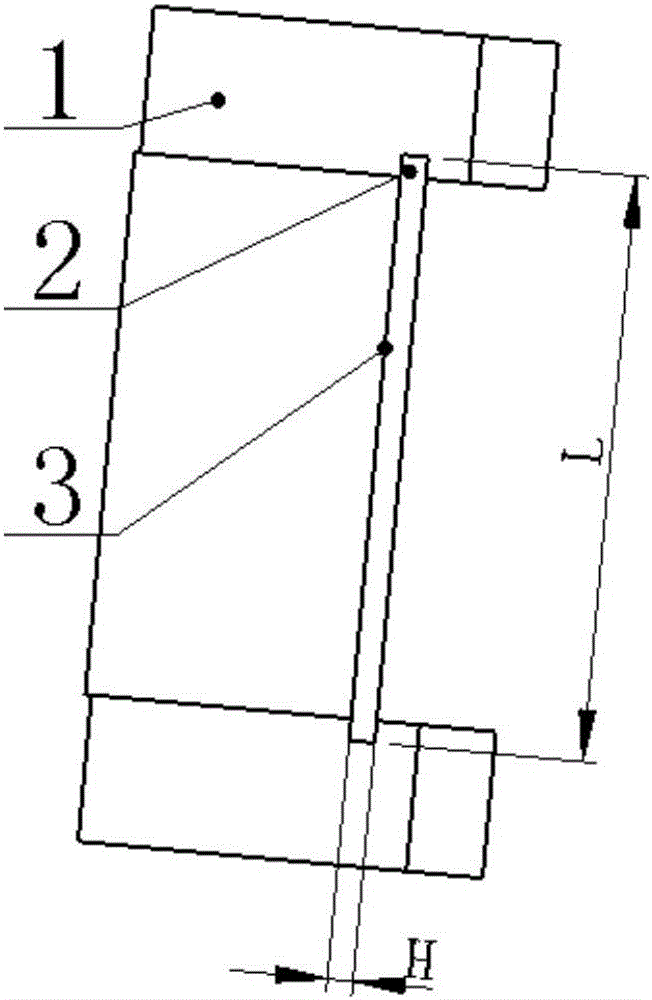

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings. The assembly tool includes a positioning body 1 and a pushing device. There is a T-shaped guide rail 2 on the positioning body 1. When using it, ensure that the angle between the bottom surface 3 of the T-shaped guide rail 2 and the horizontal plane is 5° to 75°. The width L of the T-shaped guide rail groove is compatible with the length of the porcelain sleeve. The height H of the guide rail groove is compatible with the outer diameter D of the porcelain casing, D is the outer diameter of the porcelain casing, and the bottom surface of the lower end of the T-shaped guide rail is provided with a boss; the positioning body has a guide rod through hole 11; the T-shaped guide rail of the positioning body 1D 2 There is a push rod guide hole 5 on the right side, a ceramic sleeve guide hole 10 and an outer tube positioning hole 4 on the left side, and the center of the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com