Back tool clamp of radiator

A tooling fixture and radiator technology, applied in the field of tooling fixtures, can solve the problems of cumbersome use and low clamping efficiency, and achieve the effect of simple use and high clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

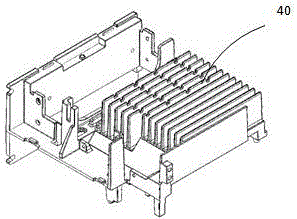

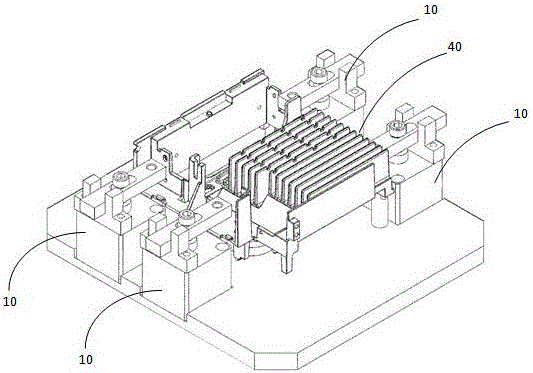

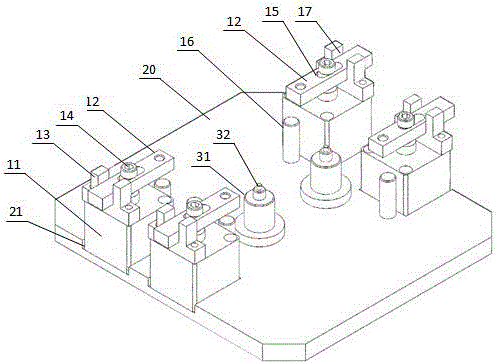

[0014] Such as Figure 2~Figure 3 As shown, it includes a bottom plate 20. Two clamping mechanisms 10 are provided on both sides of the bottom plate 20. The clamping mechanism 10 includes an air cylinder 11, a pressing plate 12, a guide seat 13 and a bolt 14. The pressing plate 12 is provided with a strip through groove 15 , The head of the bolt 14 is press-fitted on the upper end surface of the pressure plate 12, and its screw part passes through the strip groove 15 and then is threadedly connected with the piston rod of the cylinder 11. One end of the pressure plate 12 is threadedly connected with a pressure head (not shown in the figure) ). The other end is slidably connected with the sliding groove 17 of the guide seat, the bottom plate 20 is provided with a support column 16 that matches the pressure head, and the guide seat 13 is fixed on the cylinder 11;

[0015] The bottom plate 20 is also provided with a positioning mechanism corresponding to the through hole at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com