Electric welding machine capable of remotely welding

An electric welding machine, long-distance technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as trouble, electric welding machine cannot directly weld, hard work, etc., and achieve the effect of easily welding objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

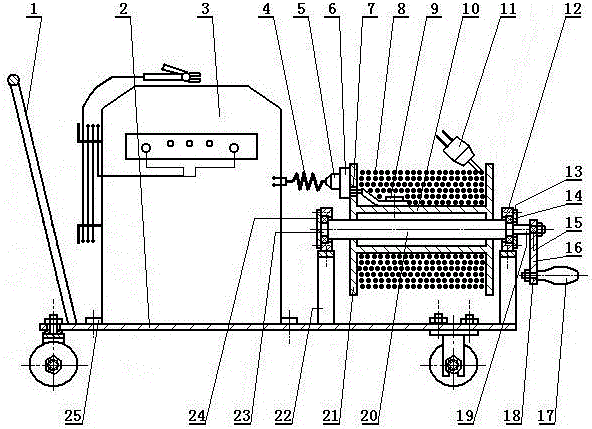

[0024] Embodiment: as shown in accompanying drawing, the specific device detail that the present invention proposes is: by trolley 1, electric welding machine 3, first plug 5, socket 6, soft wire 8, pressing plate 9, reel 10, second plug 11, Bearing seat 12, right end cover 13, bearing 14, rocking lever 16, handle 17, left / right bracket 22 and left end cover 24 constitute a kind of electric welding machine that can be welded at a long distance, and the right end of electric welding machine 3 is provided with reel 10, The reel 10 is coiled with a flexible wire 8 for long-distance connection to the power supply. The left end of the flexible wire 8 passes through the first round through hole 7 on the upper end of the left baffle plate 21 of the reel 10 to connect with the socket 6, and the socket 6 is connected with the electric welding machine 3 The first plug 5 of the power input line 4 is inserted tightly together.

[0025] The left end inside of soft lead 8 is pressed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com