Steel sheet clamping device for laser cutting

A clamping device and laser cutting technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of inability to ensure the flatness and stability of steel sheets, inconvenient manual cleaning of waste, and time-consuming and laborious clamping process, etc. problems, to achieve the effect of convenient cleaning and recycling of waste materials, ensuring flatness and stability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

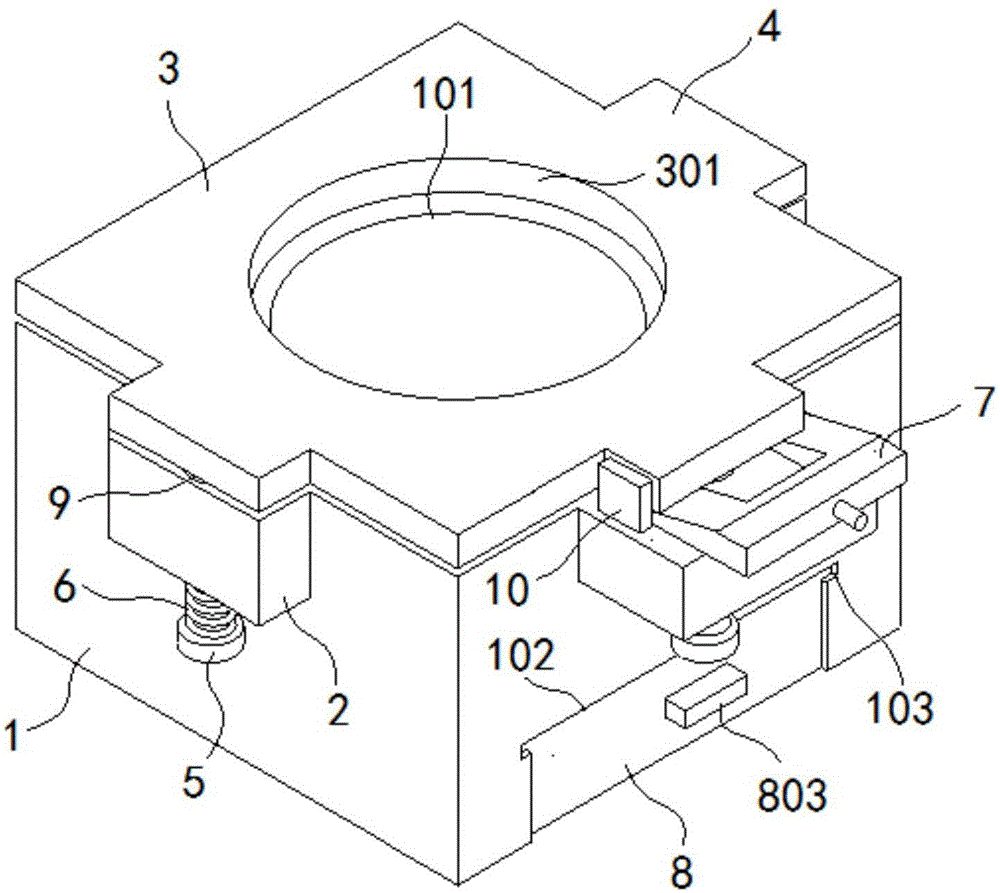

[0032] Such as figure 1 As shown, the steel sheet clamping device for laser cutting of the present invention includes:

[0033] Base 1, the center of the base 1 is formed with a first processing hole 101 penetrating the vertical direction of the base 1, and the bottom of the base 1 is formed with a through groove 102 penetrating the front and rear directions of the base 1, the through groove Sliding grooves 103 are provided on both sides of the top of 102.

[0034] The first bump 2 is formed on three sides of the base 1. The first protrusion 2 is a rectangular protrusion, and the upper end surface of the first protrusion 2 is flush with the upper end surface of the supporting base 1.

[0035] The upper pressing plate 3 is arranged above the supporting base 1, and a second processing hole 301 that penetrates the upper pressing plate 3 in the vertical direction is formed at the center of the upper pressing plate 3. The diameter of the first processing hole 101 is not greater than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com