Mechanical-electrical-liquid integration control method for multi-actuator system

A control method and multi-actuator technology, applied to fluid pressure actuation system components, mechanical equipment, servo meter circuits, etc., can solve the problem of not being applicable to metal sheets with large spans, limited control objects, and not being able to apply special metal flexibility Sheet metal and other issues to achieve the effect of improving flexibility and expandability, ensuring safe recovery, and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

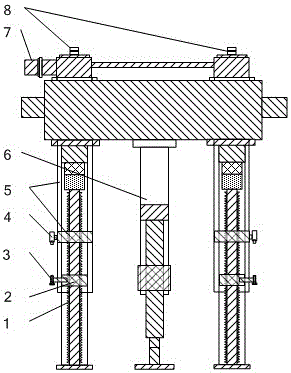

[0035]figure 1 It is a schematic diagram of the structure of the actuator related to the present invention, such as figure 1 As shown, the actuator is composed of a positioning device part and a hydraulic actuator part. The servo motor of the positioning device drives the screw to rotate through the worm gear, and then pushes the nut connected to it to move up and down in the axial direction. The nut is connected with a collision block, and the top of the screw is connected to an absolute encoder through the connecting shaft; The hydraulic cylinder drives the sleeve to move synchronously, the bottom end is connected with the special metal sheet, and a proximity switch is connected to the lower end of the sleeve, which communicates when it contacts the bumper, indicating that the hydraulic actuator is running in place.

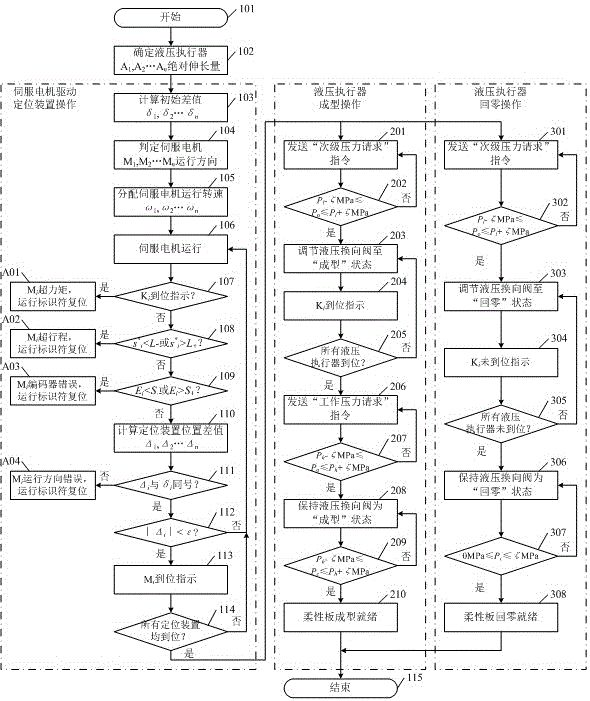

[0036] figure 2 It is a flowchart of the electromechanical-hydraulic integrated control method of the present invention, as figure 2 As shown, step 101 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com