Automatic cleaning device and cleaning method for measuring cavity of coal ash detector

A technology for automatic cleaning and measuring chambers, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as manual cleaning of the inner wall of the measuring chamber is boring, violates the automatic detection of coal ash content, and affects the production process, etc. , to achieve real-time monitoring of the cleaning effect, the degree of cleaning and ease of cleaning, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

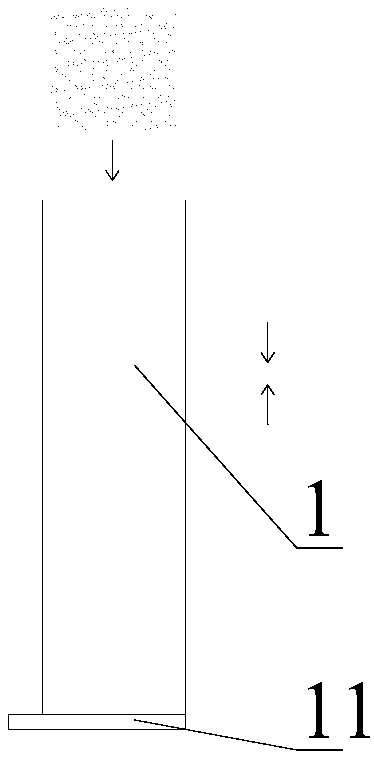

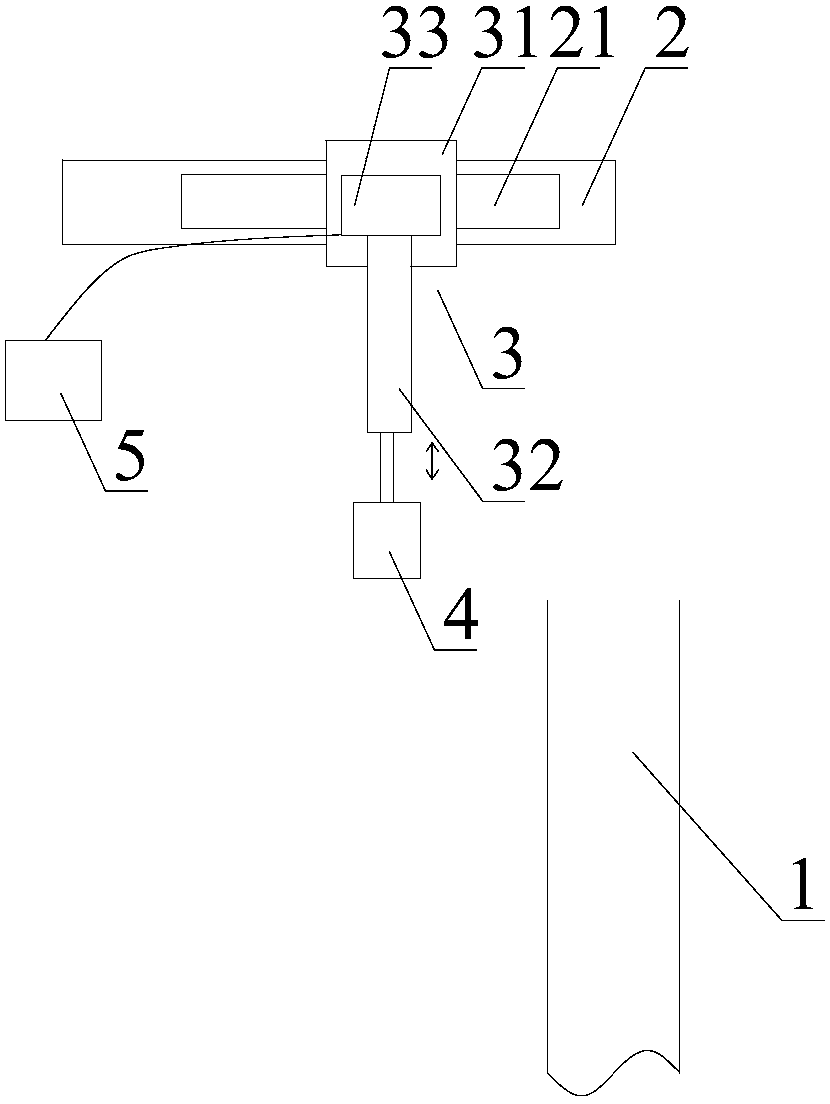

[0035] Such as figure 2 As shown, the automatic cleaning device for the measuring chamber of a coal ash content detector provided in Embodiment 1 of the present invention includes a fixed base 2 on which a mobile bracket 3 is arranged, and the mobile bracket 3 includes a horizontal slider 31, Vertical telescopic rod 32 and support drive motor 33, fixed base 2 is provided with moving slideway 21 along the horizontal direction, and the horizontal slide block 31 side of mobile support 3 is slidably embedded in moving slideway 21, and vertical telescopic rod One end of 32 is fixedly connected with the bottom of horizontal slide block 31, and the other end is fixedly connected with the top of cleaning tool 4, and support drive motor 33 is connected with horizontal slide block 31 and vertical telescopic rod 32 respectively, support drive motor 33 and control module 5 Connect and be controlled by it.

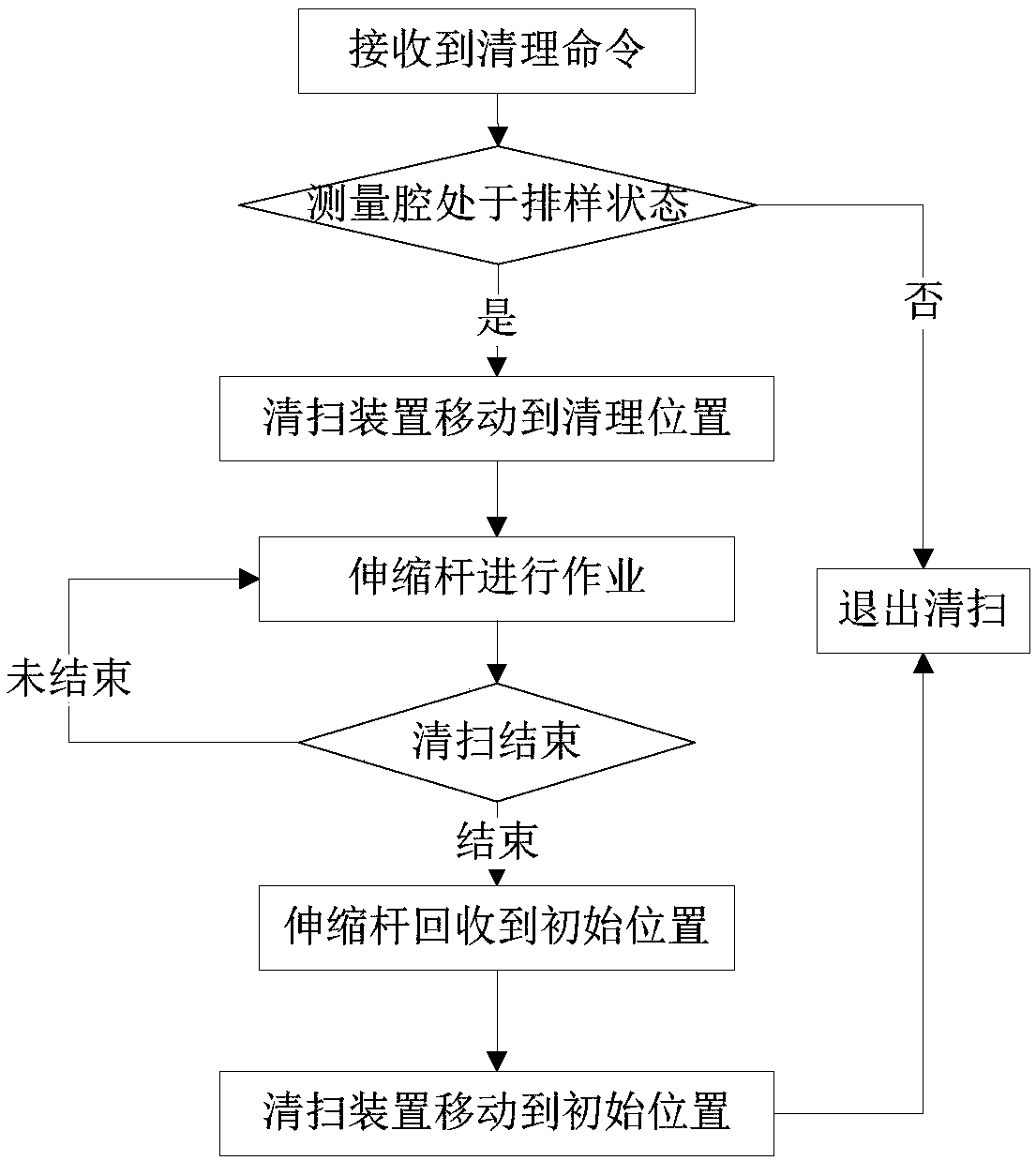

[0036] The working flow chart of the automatic cleaning device for the measureme...

Embodiment 2

[0038] Figure 4 It is a schematic structural diagram of an automatic cleaning device for the measurement chamber of a coal ash detector provided in Embodiment 2 of the present invention. The structure of the automatic cleaning device in this embodiment is similar to that in Embodiment 1. The difference lies in that this The automatic cleaning device of the embodiment also includes a cleaning rotating motor 6 installed at the lower end of the vertical telescopic rod 32 , and the two ends of the cleaning rotating motor 6 are respectively connected with the control module 5 and the cleaning tool 4 .

[0039] The working process of the automatic cleaning device for the measurement chamber of the coal ash detector provided in this embodiment is similar to that of Embodiment 1 when cleaning the inner wall of the measurement chamber. The difference is that when the cleaning tool is inserted into the measurement chamber, the control module issues a command While the bracket drives the ...

Embodiment 3

[0041] Figure 5 It is a schematic structural diagram of an automatic cleaning device for the measurement chamber of a coal ash content detector provided in Embodiment 3 of the present invention. The structure of the automatic cleaning device in this embodiment is similar to that in Embodiment 2. The difference lies in that this The cleaning tool 4 of the embodiment is a cavity structure, and cleaning brushes 41 are evenly arranged around the cavity; six high-pressure air outlet pipes 42 and twelve dust suction holes 43 are evenly arranged in the gaps between the cleaning brushes 41, and the upper end of the cavity is provided with There are high-pressure air inlet pipes 44 and negative pressure air pipes 45. Six high-pressure air outlet pipes 42 are connected in series with the high-pressure air inlet pipes 44 in the cavity and extend out of the cavity. The high-pressure air inlet pipes 44 are provided with high-pressure air valves on the part outside the cavity 47. The high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com