Device for turning transformer plate radiators during spraying paint

A flipping device and radiator technology, applied in the direction of spraying device, etc., can solve the problems affecting product paint quality and large difference in paint thickness, so as to improve work efficiency, save energy consumption, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

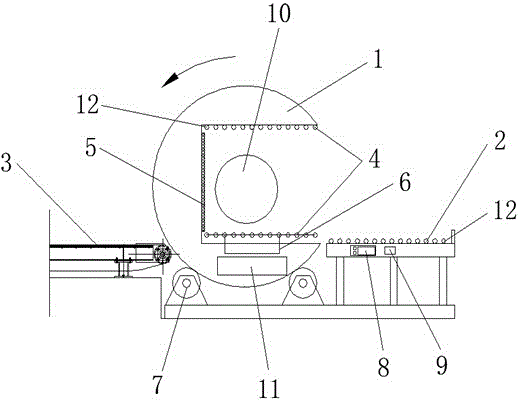

[0010] like figure 1 As shown in the figure, a paint overturning device for finned radiators for transformers includes an overturning frame 1, a conveyor belt 2, and a waiting area 3. The bottom of the overturning frame 1 is provided with a support pulley 7, and the overturning frame 1 is provided with a transmission belt 4 and a beam 5. , the compression plate 6 and the motor 10, the transmission belt 4 is arranged on the upper and lower sides of the flip frame 1, the servo motor 12 is installed inside the conveyor belt 4, and the two rollers are connected, the beam 5 is arranged on the left side of the flip frame 1, and the pressure The tightening plate 6 is arranged at the bottom of the conveyor belt 4, the cylinder 11 is installed at the bottom of the pressing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com