Rapidly returning device for roll crusher

A roll crusher and flash back technology, which is applied in the direction of grain processing, etc., can solve the problems of excessive feeding of materials, material blockage, hard objects entering, etc., and achieve the effect of meeting crushing requirements and improving speed and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

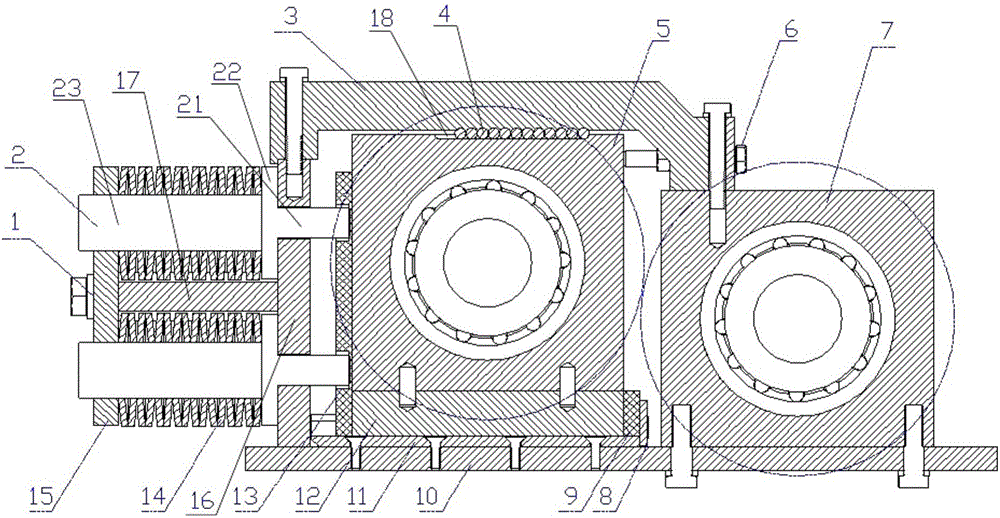

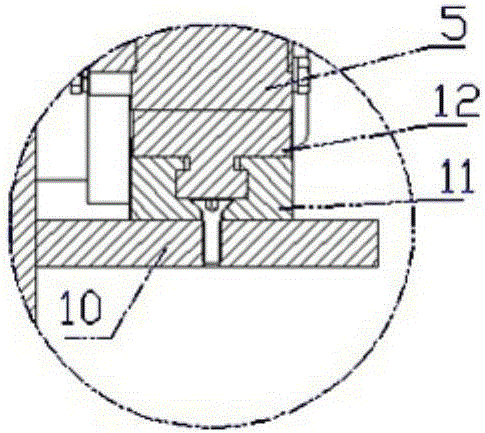

[0021] see figure 1 , figure 2 , a flashback device of a roller crusher according to the present invention includes a base 10 on which a fixed bearing seat 7 and a sliding bearing seat 5 are arranged side by side, and a frame-type sliding bearing seat is arranged on the outside of the sliding bearing seat. Seat, the frame-type sliding seat includes a connecting arm 3, a vertical support plate 16, a T-shaped slideway 11, one end of the connecting arm is fixedly connected with the top of the vertical support plate, and the other end of the connecting arm It is fixedly connected with the top of the fixed bearing seat, and the T-shaped slideway is fixed on the base; the bottom of the sliding bearing seat is connected with the T-shaped slideway through the T-shaped slide rail 12, and the sliding The top of the bearing seat is connected with the connecting arm through a ball 4; an elastic return mechanism is arranged on the vertical support plate.

[0022] see figure 1 , in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com