Manufacturing method of hidden bilayer structure for intelligent bed

A technology of double-layer structure and manufacturing method, which is applied to bed frames, applications, household appliances, etc., can solve the problems of bunk beds that cannot be moved up and down at will, and occupies a large space, and achieves the effects of avoiding manual labor, saving space, and improving friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

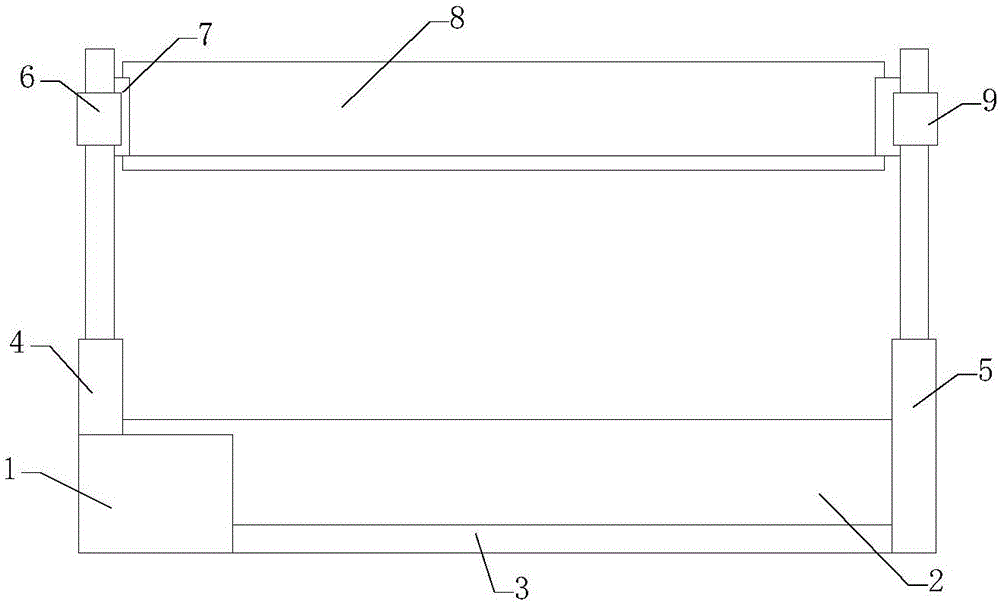

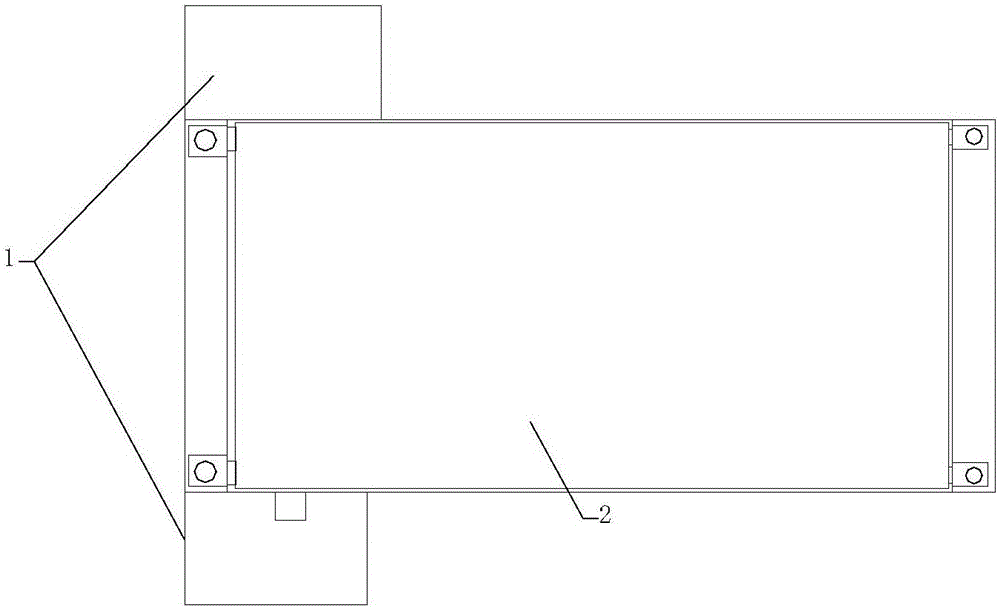

[0025] Such as figure 1 As shown, a method for manufacturing an invisible double-layer structure for a smart bed, including a control unit and a drive unit, the control unit includes a control box 1, and the control box 1 is provided with a motor and an air pump. The control box 1 is also provided with a control panel;

[0026] The drive unit includes the main bed frame 2, the main telescopic rod 4 and the auxiliary telescopic rod 5 arranged at the four corners of the main bed frame 2, the auxiliary bed 8 arranged in the main bed frame 2 and the air bed 3 arranged in the main bed frame 2. One end of the main telescopic rod 4 and the auxiliary telescopic rod 5 is installed on the main bed frame 2, the other end of the main telescopic rod 4 and the auxiliary telescopic rod 5 is connected with the auxiliary bed 8, and the air bed 3 is located on the auxiliary bed. Below the bed 8 and installed in the main bed frame 2;

[0027] The motor is connected with the main expansion rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com