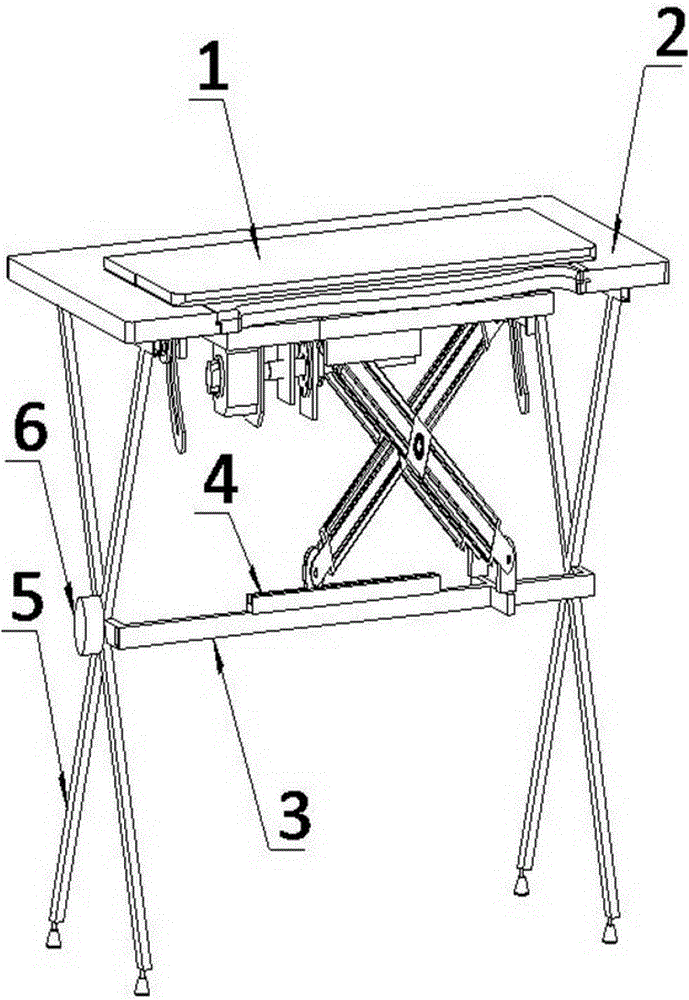

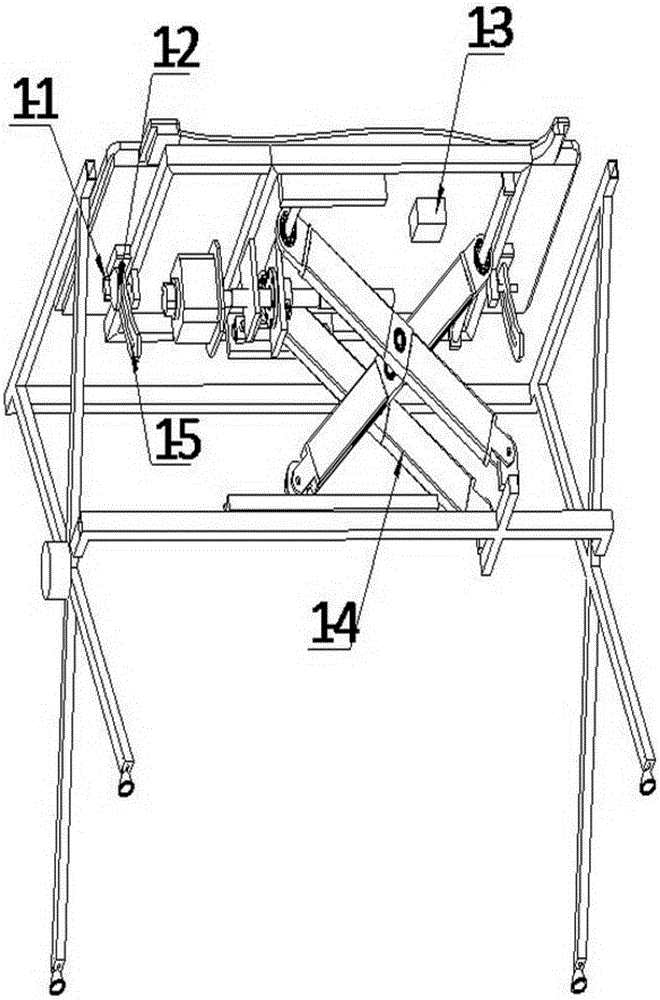

Automatic lifting angle-adjustable type double-sided table controlled based on sensor and operating method thereof

An automatic lifting and adjustable technology, which is applied to the legs of general furniture, extendable tables, tables with variable table heights, etc., can solve the problem of fragile table valuables, easy to overturned tables, and unstable folding tables and other problems, to achieve the effect of compact structure, small space occupation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

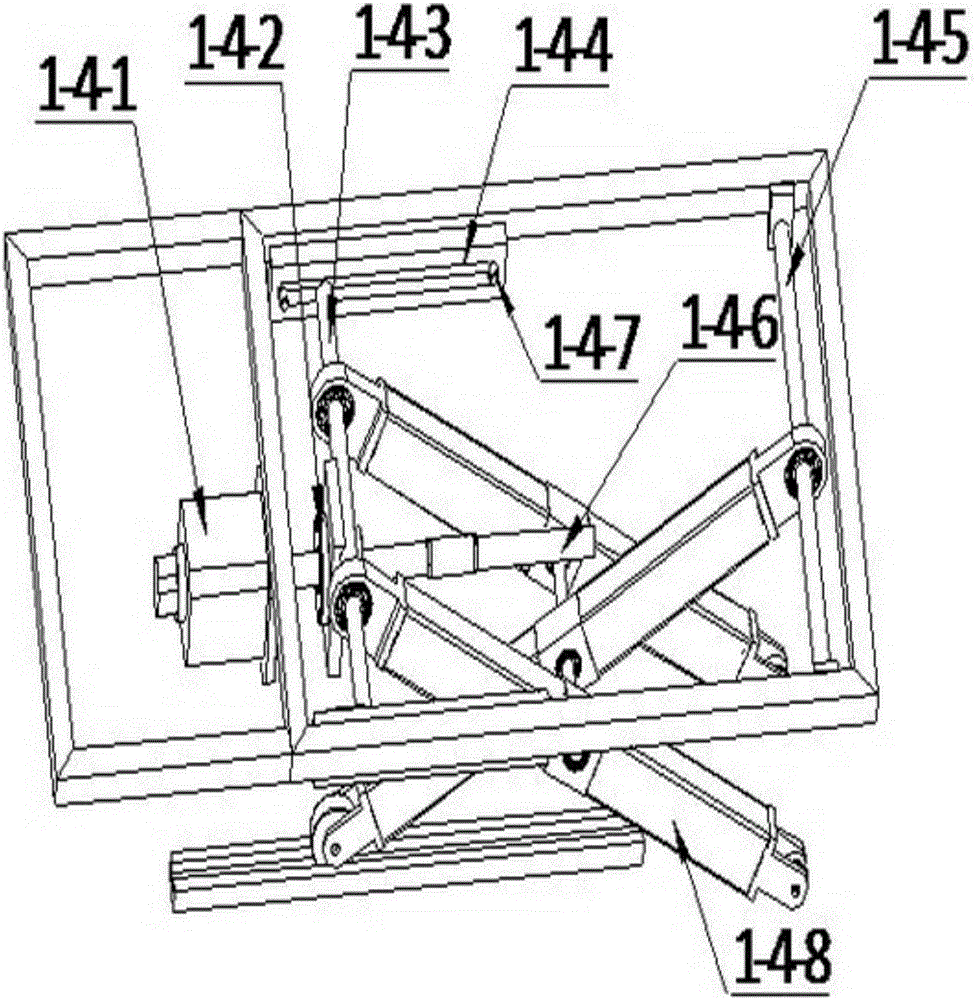

[0045] The pole 1-4-8-1 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0046] Step 1: Add 4120 parts of ultrapure water with a conductivity of 3.22μS / cm to the reactor, start the stirrer in the reactor, rotate at 160rpm, start the heat pump, and increase the temperature in the reactor to 127℃; 81 parts of (3-phenoxyphenyl)methyl-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanecarboxylate, 2-[4-(4-chlorobenzene Formyl)phenoxy)-2-methylpropionic acid 168 parts, 2,3,5,6-tetrafluoro-4-methylbenzyl (Z)-(1RS,3RS)-3-(2-chloro -2,3,3-trifluoroprop-1-enyl)-2,2-dimethylcyclopropane carboxylate 59 parts, stir until completely dissolved, adjust the pH to 3.5, and adjust the stirrer speed to 81rpm , The temperature is 156℃, the esterification reaction is 13 hours;

[0047] Step 2: Take 130 parts of 5-hydroxy-4-(p-hydroxybenzyl)-3',3-dimethoxybibenzyl, N,N'-[3,3'-dichloro[1,1' -Biphenyl]-4,4'-diyl]bis[4-[(2-chlorophenyl)azo]-3-...

Embodiment 2

[0052] The pole 1-4-8-1 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0053] Step 1: Add 5360 parts of ultrapure water with conductivity of 6.85μS / cm to the reactor, start the stirrer in the reactor, rotate at 264rpm, start the heat pump, and increase the temperature in the reactor to 173℃; add sequentially 285 parts of (3-phenoxyphenyl)methyl-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanecarboxylate, 2-(4-(4-chlorobenzene) Formyl)phenoxy)-2-methylpropionic acid 292 parts, 2,3,5,6-tetrafluoro-4-methylbenzyl (Z)-(1RS,3RS)-3-(2-chloro -2,3,3-trifluoroprop-1-enyl)-2,2-dimethylcyclopropane carboxylate 82 parts, stir until completely dissolved, adjust the pH to 8.6, and adjust the stirrer speed to 192rpm , The temperature is 212℃, and the esterification reaction is 20 hours;

[0054] Step 2: Take 173 parts of 5-hydroxy-4-(p-hydroxybenzyl)-3',3-dimethoxybibenzyl, N,N'-[3,3'-dichloro[1,1' -Biphenyl]-4,4'-diyl]bis[4-[(...

Embodiment 3

[0059] The pole 1-4-8-1 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0060] Step 1: Add 4730 parts of ultrapure water with a conductivity of 4.93μS / cm to the reactor, start the stirrer in the reactor, rotate at 212rpm, start the heat pump, and increase the temperature in the reactor to 148℃; add sequentially 181 parts of (3-phenoxyphenyl)methyl-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanecarboxylate, 2-(4-(4-chlorobenzene) Formyl)phenoxy)-2-methylpropionic acid 235 parts, 2,3,5,6-tetrafluoro-4-methylbenzyl (Z)-(1RS,3RS)-3-(2-chloro -2,3,3-trifluoroprop-1-enyl)-2,2-dimethylcyclopropane carboxylate 69 parts, stir until completely dissolved, adjust the pH to 6.1, and adjust the stirrer speed to 136rpm , The temperature is 186℃, and the esterification reaction is 16 hours;

[0061] Step 2: Take 151 parts of 5-hydroxy-4-(p-hydroxybenzyl)-3',3-dimethoxybibenzyl, N,N'-[3,3'-dichloro[1,1' -Biphenyl]-4,4'-diyl]bis[4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com