Producing method of plantain herb-green tea instant tea

A production method and technology for instant tea, applied in the direction of tea, tea extraction, food science, etc., to achieve the effects of shortening extraction time, high extraction rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0050] Green tea is prepared by the following production process:

[0051] (1) The raw material is single bud. After the fresh leaves are picked, they are collected in stages and placed in a clean bamboo plaque in a cool, ventilated place for 7 hours, and their moisture content is reduced to 70%.

[0052] (2) Microwave fixing: Put the fresh leaves that have been dried on the spread into the microwave fixing machine for microwave fixing. The M700 microwave oven of Guangdong Midea Microwave Manufacturing Co., Ltd. is used. The fixing temperature is 145℃. At this time, the moisture content of the green leaves was 52%.

[0053] (3) Initial kneading: Preliminary kneading was performed on the green leaves, and a 255-type kneading machine was used for warm kneading.

[0054] (4) Secondary microwave fixing: The above-mentioned greening leaves were subjected to microwave supplementary killing again, and the M700 microwave oven was also used. The moisture content of the secondary gre...

Embodiment 1

[0058] Adopt the following production process to prepare plantain green tea instant tea:

[0059] (1) The plantain was microwaved in an M700 microwave oven to kill the green and inactivate the enzyme, the amount of leaf input was 60g, the microwave power was 500W, and the greening time was 40s;

[0060] (2) the psyllium after fixing is pulverized to 100 meshes, the green tea of Preparation Example 1 and the commercially available licorice are pulverized to 20 meshes, 40 meshes respectively;

[0061] (3) Mix the pulverized plantain, green tea and licorice according to the weight ratio of 20:50:30;

[0062] (4) The mixture obtained in step (3) is leached with a mixed solution with a volume ratio of water and ethanol of 100:20. During leaching, protease, cellulase and pectinase are added in a mass ratio of 1:1:1. The compound enzyme was enzymolyzed, the mass volume fraction of the compound enzyme was 0.5%, the volume and mass ratio of the extract to the mixture was 500mL: 100g...

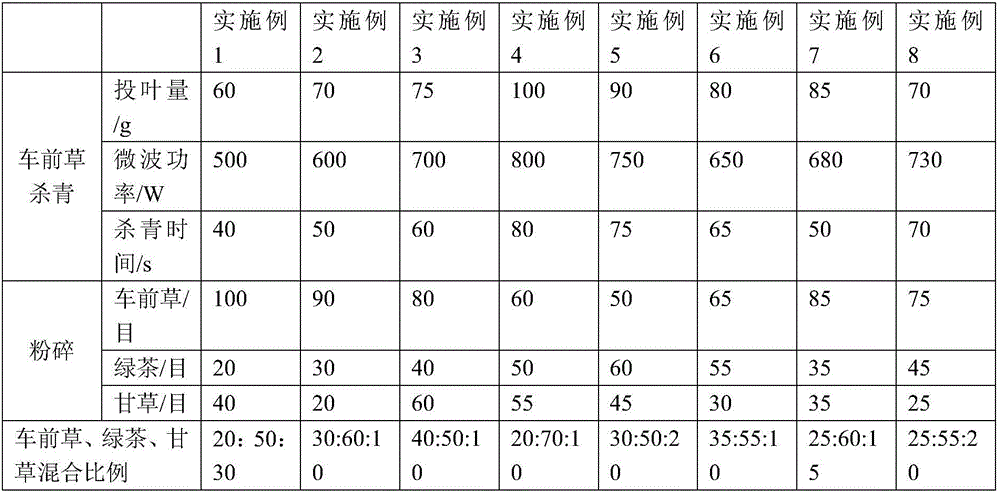

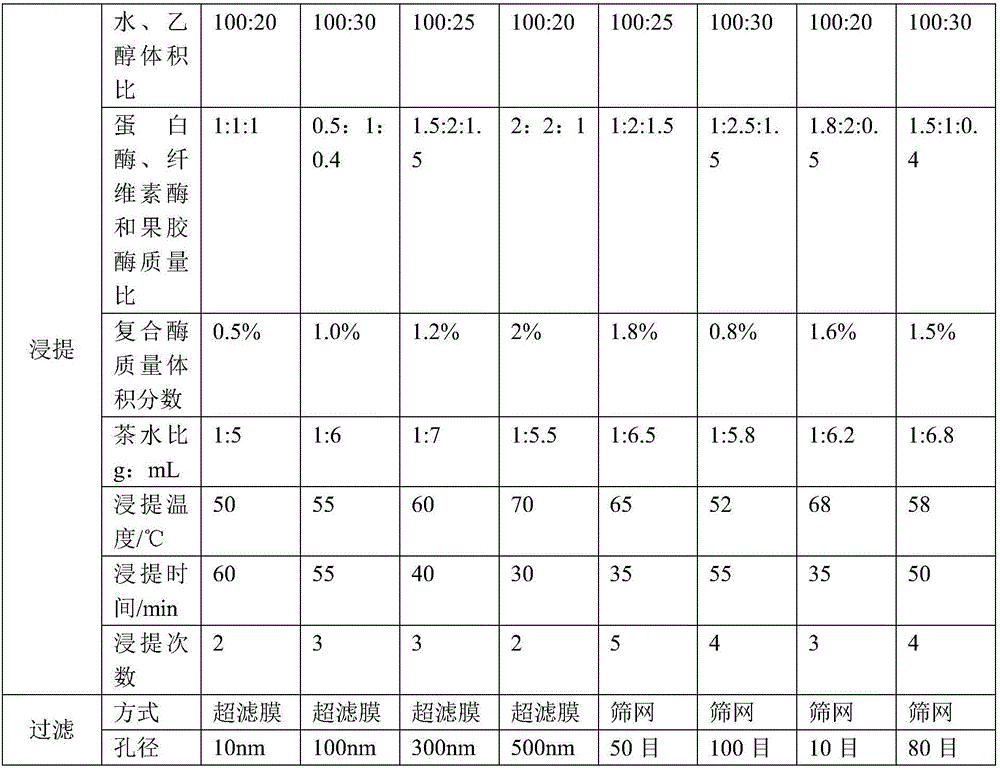

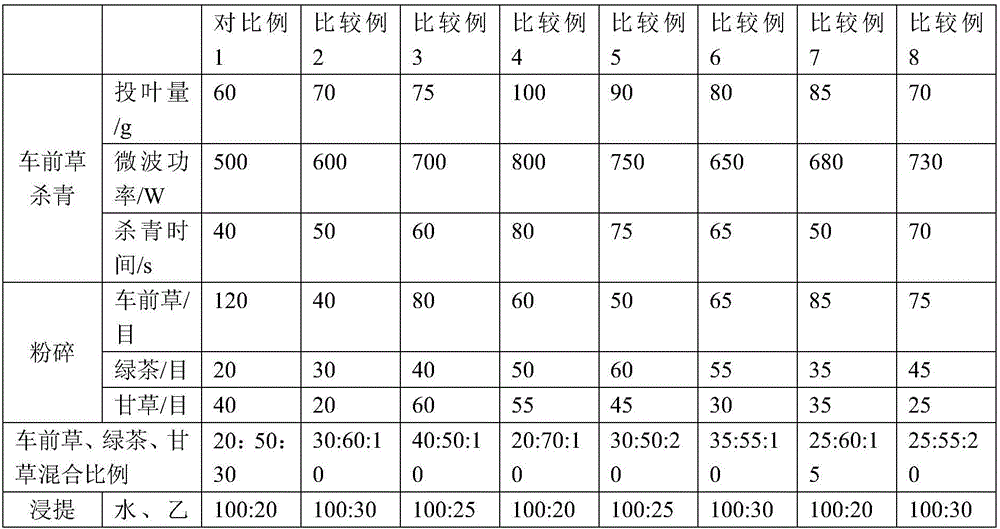

Embodiment 2-8

[0066] The instant tea process is basically the same as that in Example 1, and the specific process parameters are different from the process conditions in Table 1. In addition, Examples 7 and 8 used common commercial green tea as a raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com