Power cable deicing device

A power cable and power line technology, which is applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of easily damaged power lines and unsatisfactory cutting effects, so as to avoid jamming or breaking, improve the deicing effect, and facilitate The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

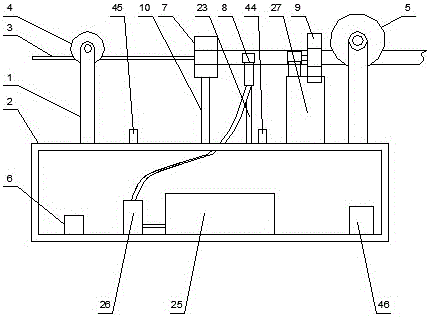

[0032] Such as Figure 1 to Figure 7 As shown, a power cable deicing device includes a running mechanism and a frame 2 connected below the running mechanism through a mechanical arm 1. The road wheels 4 and the front road wheels 5 that are stuck on the ice-covered part of the power line 3 are not removed. The frame 2 is provided with a deicing mechanism, and the deicing mechanism is located between the rear road wheels 4 and the front road. Between the wheels 5, a wireless controller 6 is installed on the left side inside the frame 2, and the traveling mechanism is connected to the wireless controller 6 by electrical signals; the deicing mechanism includes an ice-coated crushing module 7 from left to right , Waterjet segmentation module 8 and pre-cutting module 9.

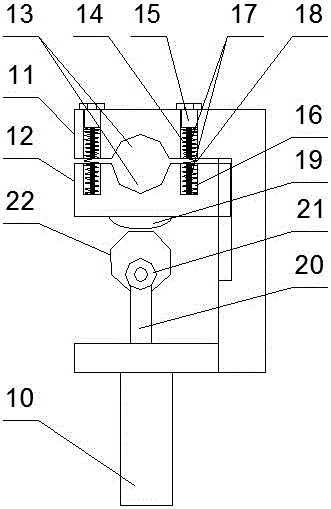

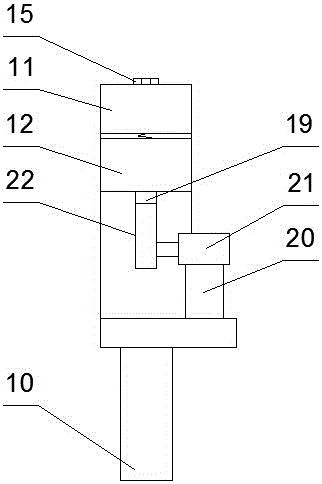

[0033] The ice-coated crushing module 7 includes a crushing module bracket 10 arranged on the frame 2, a semi-frame-shaped fixed jaw 11 with an opening on the left side of the upper end of the crushing module brac...

Embodiment 2

[0041] Such as Figure 8 As shown, the difference between it and Embodiment 1 is that: the top of the water tank 25 is provided with an opening, the opening is provided with a funnel 41 for receiving ice and snow, and the top of the frame 2 is provided with a gap corresponding to the position of the funnel 41 for receiving ice and snow 42 is used to install a heating module 43 at the bottom of the water tank 25 and the heating module 43 is electrically connected to the wireless controller 6 .

[0042] In this embodiment, an opening is set on the top of the water tank, and an ice and snow funnel is arranged on the opening, and a gap is provided at the top of the frame corresponding to the position of the ice and snow funnel to collect ice cubes falling from the power line, and the bottom of the water tank Set up a heating module and connect the heating module to the wireless controller with electrical signals, so that during the deicing process, some falling ice cubes can be co...

Embodiment 3

[0044] Such as Figure 9 As shown, the difference between it and Embodiment 2 is that: the center of gravity adjustment module is arranged at the bottom of the frame 2, and the center of gravity adjustment module includes a counterweight 47 that is slidingly arranged at the bottom of the frame 2 using a dovetail structure and is arranged on the bottom of the frame 2. The automatic telescopic rod 48 on the left side of the bottom of the frame 2, the free end of the automatic telescopic rod 48 is connected with the counterweight 47, and the automatic telescopic rod 48 is connected with the wireless controller 6 by electrical signals.

[0045] The automatic telescopic rod 48 is an electric telescopic rod.

[0046] In this embodiment, a center-of-gravity adjustment module is provided at the bottom of the frame to adjust the center of gravity of the device, so as to avoid the instability of the center of gravity from affecting the work of the device; The position of the block can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com