Electromagnetic fixator

A fixer and electromagnetic technology, which is applied to non-mechanical transmission-operated locks, building locks, buildings, etc., can solve the problems of unreliable fixation, time-consuming and troublesome fixation, and achieve the effect of reliable fixation and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

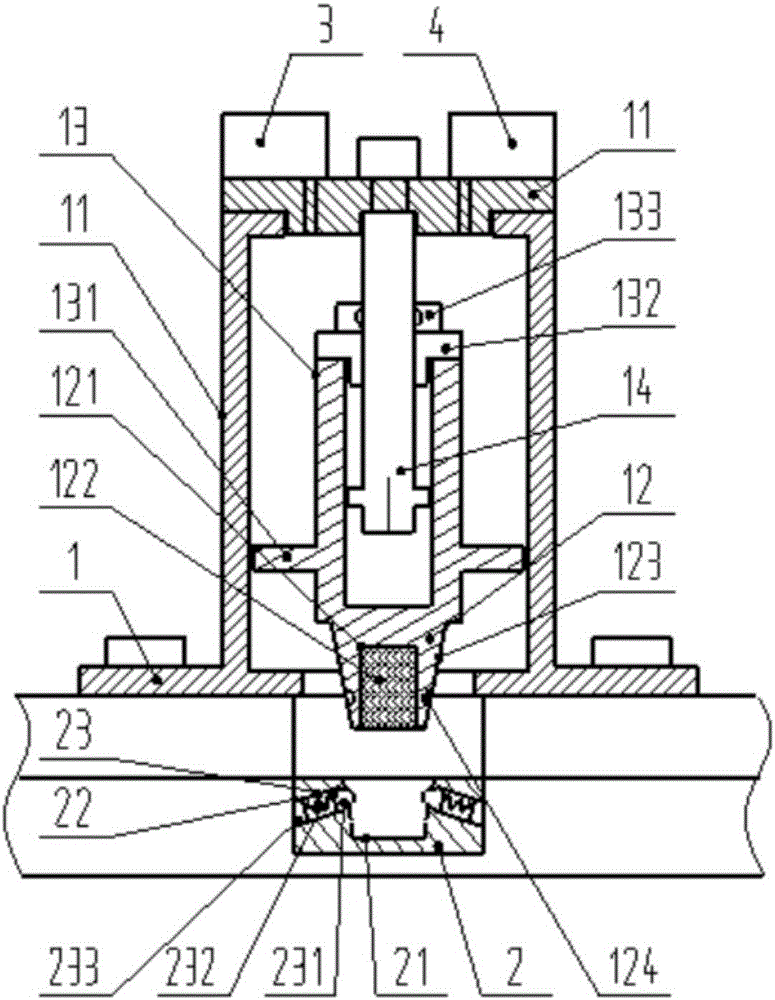

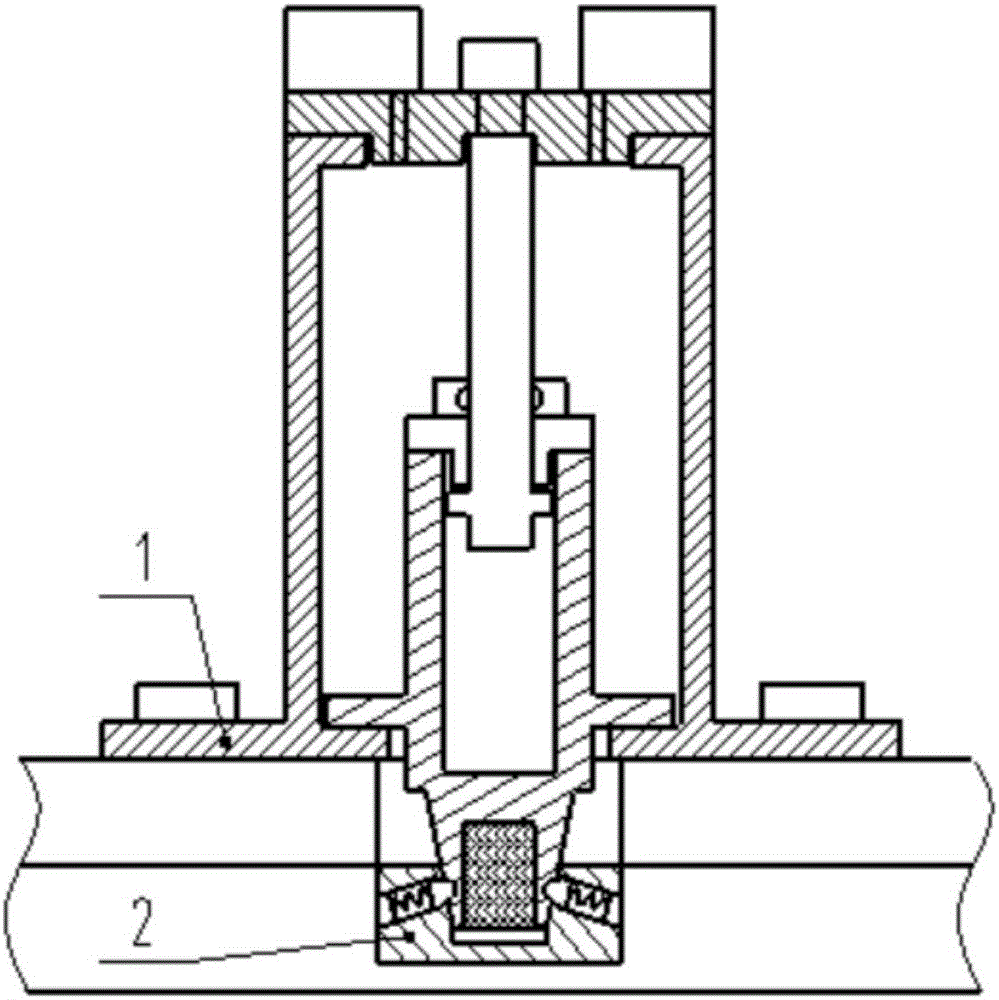

[0021] Such as Figure 1-2 As shown, an electromagnetic holder includes a fixing base 1 and a permanent magnet base 2. The fixing base includes a sleeve 11, a lock tongue 12 inside the sleeve, a core cylinder 13 fixed at the tail end of the lock tongue, and a guide core. The core rod 14 that slides in the axial direction of the barrel and the cover plate 15 connected to the upper end of the sleeve, the front end of the lock tongue has a blind hole 121, and an electromagnet 122 is embedded in the blind hole, the core rod is fixed on the lower surface of the cover plate, and the lock tongue The front end is provided with two slopes 123, which can facilitate the insertion of the dead bolt into the groove of the fixed part, and a plurality of grooves 124 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com