Magnetic suspension bearing control system capable of realizing resuspension after destabilization and control method thereof

A technology of magnetic levitation bearing and control system, applied in the direction of bearing, shaft and bearing, shaft, etc., can solve the problems of rotor or stator damage, uncontrollable recovery of suspension process, etc., to reduce impact force, reduce vibration amplitude, and facilitate recovery control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

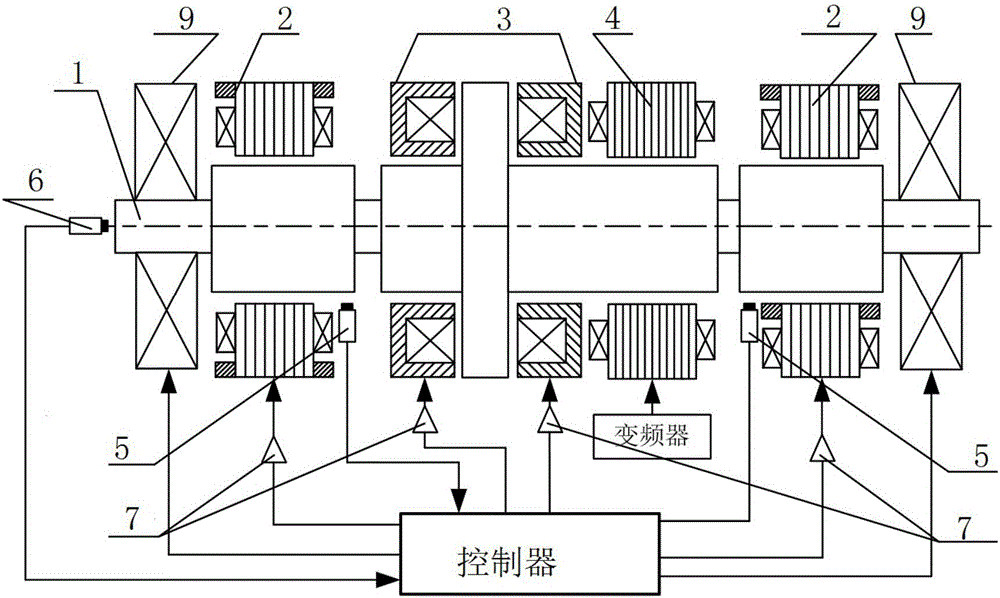

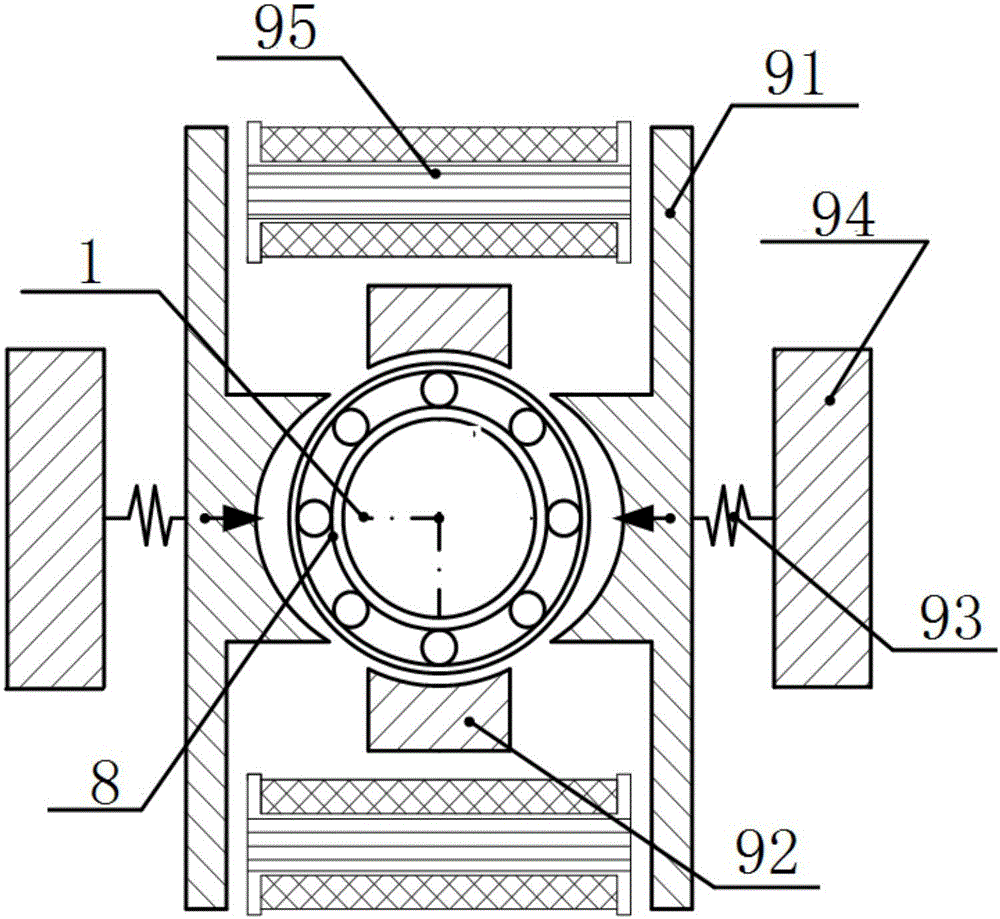

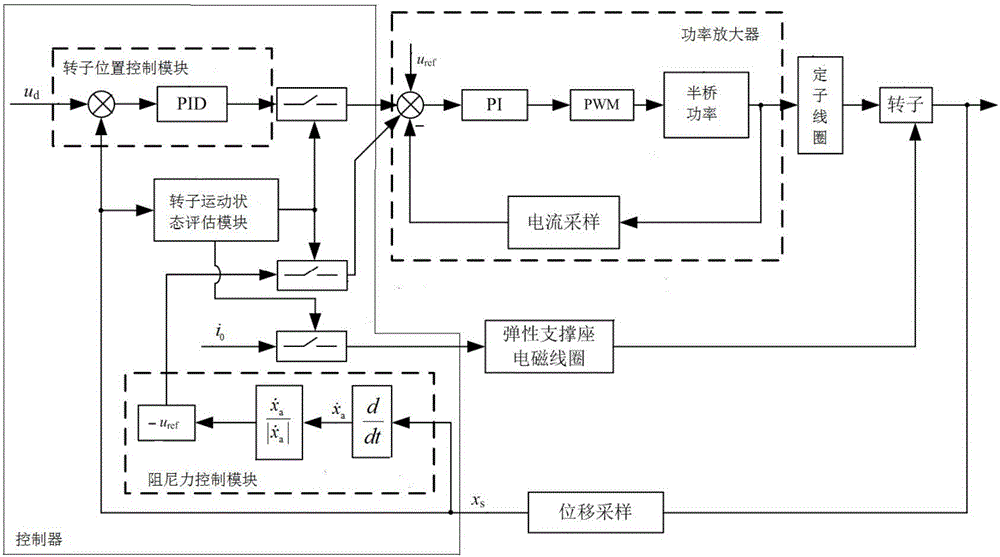

[0043] to combine figure 1 and figure 2 , a magnetic suspension bearing control system that achieves resuspension after instability in this embodiment includes a rotor 1, a radial magnetic suspension bearing stator 2, an axial magnetic suspension bearing stator 3, a motor stator 4, a radial displacement sensor 5, an axial displacement The sensor 6, the controller, the power amplifier 7 and the frequency converter used to control the motor stator 4, the axial displacement sensor 3 and the radial displacement sensor 5 are all connected to the controller, the radial magnetic suspension bearing stator 2 and the axial magnetic suspension bearing stator 3 The stator coils inside are all connected to the power amplifier 7, and each power amplifier 7 is connected to the controller, and a ball bearing 8 that rotates with the rotor is respectively installed at the two ends of the rotor 1, and each ball bearing 8 The outer cover is provided with an elastic support seat 9, and the use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com