Enzyme preparation for tobacco processing and application of enzyme preparation

A technology of enzyme preparation and tobacco leaves, which is applied in the field of reducing miscellaneous flavors of tobacco leaves, can solve the problems of long storage period, large backlog of funds, and low production cost, and achieve the effects of improving tobacco miscellaneous flavors, good application prospects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

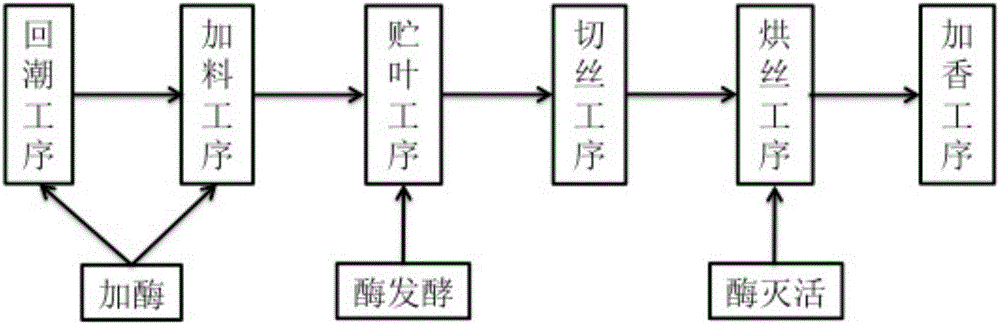

Method used

Image

Examples

Embodiment 1~8

[0032] The sensory evaluation of the tobacco leaf group after the treatment of the enzyme preparation in Examples 1-8

[0033] Embodiments 1 to 8 select different tobacco leaf groups (see Table 2) respectively, select different enzyme formulations (see Table 3) for the characteristics of each leaf group, and treat 8 different types of tobacco leaves according to the process parameters in Table 4. Leaves were treated with enzymes.

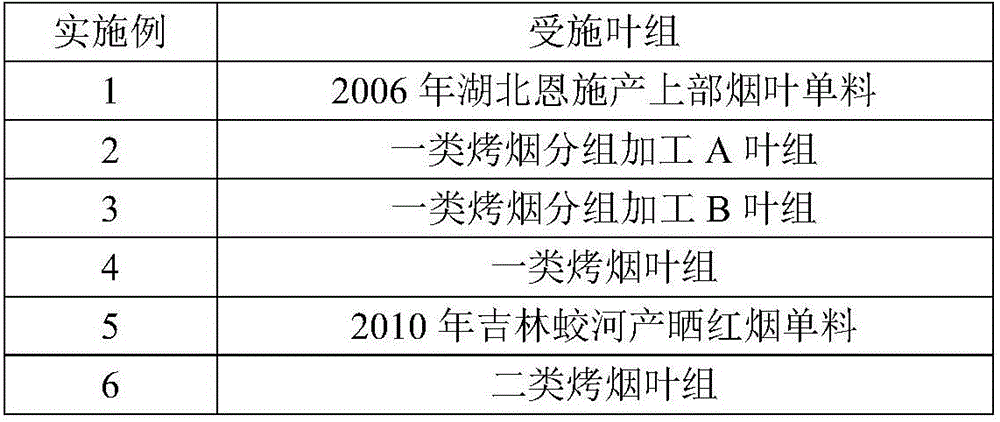

[0034] The tobacco leaf group that uses in the embodiment 1~8 of table 2

[0035]

[0036]

[0037] Composition and application rate (enzyme activity unit / gram tobacco leaf) of enzyme preparation in table 3 embodiment 1~8

[0038] Example 1 2 3 4 5 6 7 8 α-amylase 6 15 23 39 80 121 177 27 β-amylase 9 18 2 22 14 0 160 12 Glucoamylase 96 137 111 169 600 459 485 189 Pullulanase 9 130 151 168 5 169 320 6 cellulase 160 190 152 88 5 175 23 23 hemicellulase 199 ...

Embodiment 9

[0046] Embodiment 9 enzyme activity assay method

[0047] (1) α-amylase: Add 1 mL of 0.5% soluble starch solution and 2.5 mL of disodium hydrogen phosphate-citric acid buffer solution at pH 4.2 to a 10 mL test tube successively, and preheat at 40° C. for 10 min. Then add 0.5mL enzyme solution diluted multiple times, after 5min at 40°C, add 0.1mol / L H 2 SO 4 1 mL to stop the reaction. Then take 2mL of reaction solution and 0.5mL of 0.5% KI-I2 solution to develop color, and measure OD 620 . After the starch concentration of the reaction solution was compared with the starch gradient standard curve, the enzyme activity was calculated.

[0048] At pH 4.2 and temperature 40°C, the amount of enzyme required to hydrolyze 1 mg of soluble starch in 5 minutes is one unit of enzyme activity.

[0049] (2) β-amylase: Add 1 mL of 0.5% soluble starch solution and 2.5 mL of disodium hydrogen phosphate-citric acid buffer solution at pH 4.2 to a 10 mL test tube successively, and preheat a...

Embodiment 10

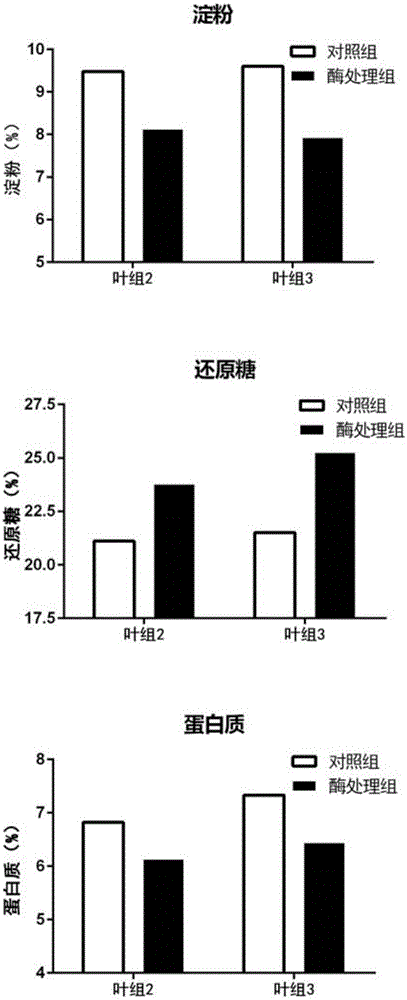

[0068] Chemical composition analysis of tobacco leaf group after embodiment 10 enzyme treatment

[0069] Get the tobacco leaf group after enzyme treatment in embodiment 2 and embodiment 3, have carried out the analysis of shredded tobacco chemical composition with pure water treatment contrast sample, have detected the content of starch, reducing sugar, total protein, the result is as follows figure 2 shown.

[0070] The chemical composition analysis results show that the enzyme preparation treatment of the present invention can significantly reduce the content of macromolecular compounds harmful to tobacco smoking quality, thereby improving the quality of tobacco leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com