Method for enhancing tar removal and CO2 trapping of chemical-chain-gasification hydrogen production process

A technology for enhancing chemistry and tar, which is applied in the direction of gasification process, chemical industry, sustainable manufacturing/processing, etc. It can solve the problems of absorbent deactivation, poor mechanical strength of absorbent, etc., so as to improve reactivity, reduce operation and maintenance, The effect of reducing the concentration of tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

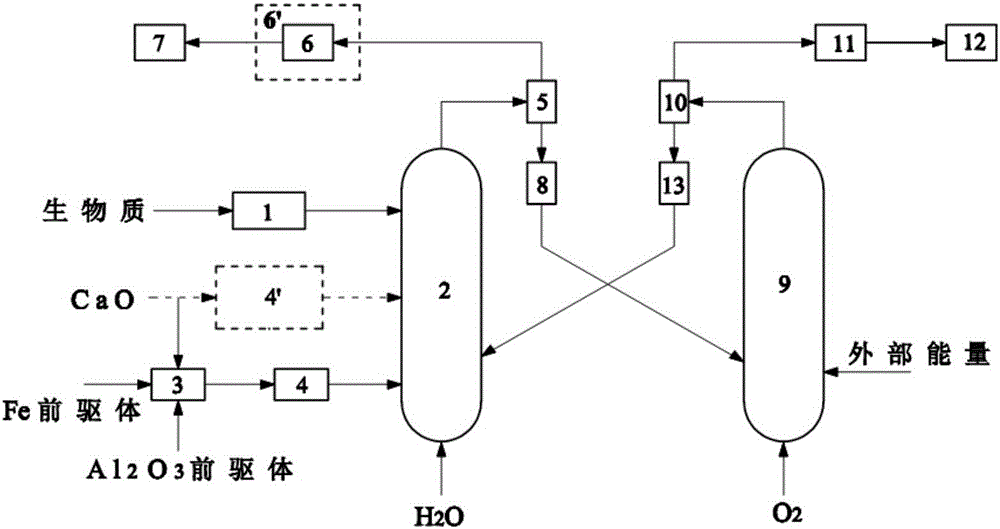

[0031] Fuel such as biomass enters the gasifier 2 through the feeding device 1 . CaO precursors (such as quicklime) and Al 2 o 3 Precursor Al 3 (NO 3 ) 3 9H 2 O, iron compound precursor Fe(NO 3 ) 3 9H 2 O is integrated with each other in modification unit 3 to form a new composite absorbent. Quicklime, Al 3 (NO 3 ) 3 9H 2 O, Fe(NO 3 ) 3 9H 2 The mass ratio of O is controlled at about 1:1.08:0.72. In the resulting composite absorbent, the main components include CaO, Ca 12 Al 14 o 33 , Fe 2 o 3 , the mass ratio of the above three components is about 1:0.33:0.17. The composite absorbent coming out of the modifying unit then enters the absorbent feeding unit 4 and is transported to the gasifier.

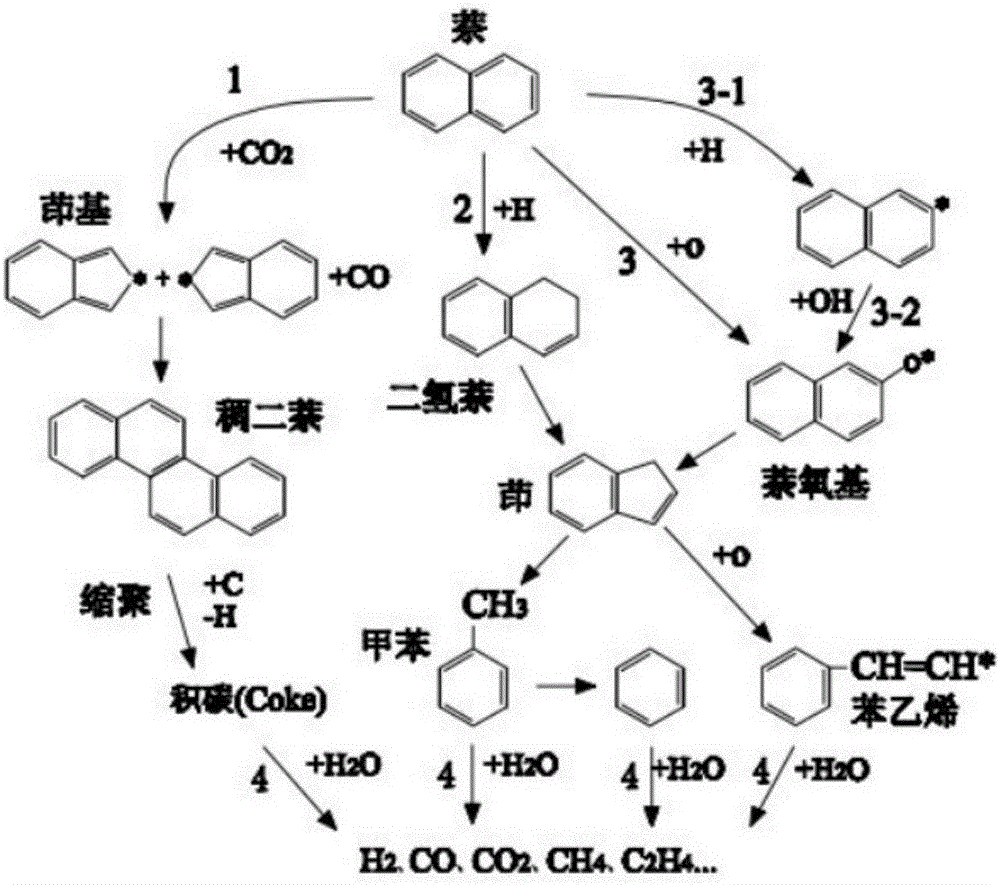

[0032] A typical temperature at which a biomass gasifier operates is 750°C. Biomass undergoes a thermal decomposition reaction as shown in formula (1) at high temperature to generate CO, H 2 , CO 2 、CH 4 , a small amount of other small molecular hydrocarbon gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com