A kind of up-conversion nano-material that can respond to pH value and its preparation method

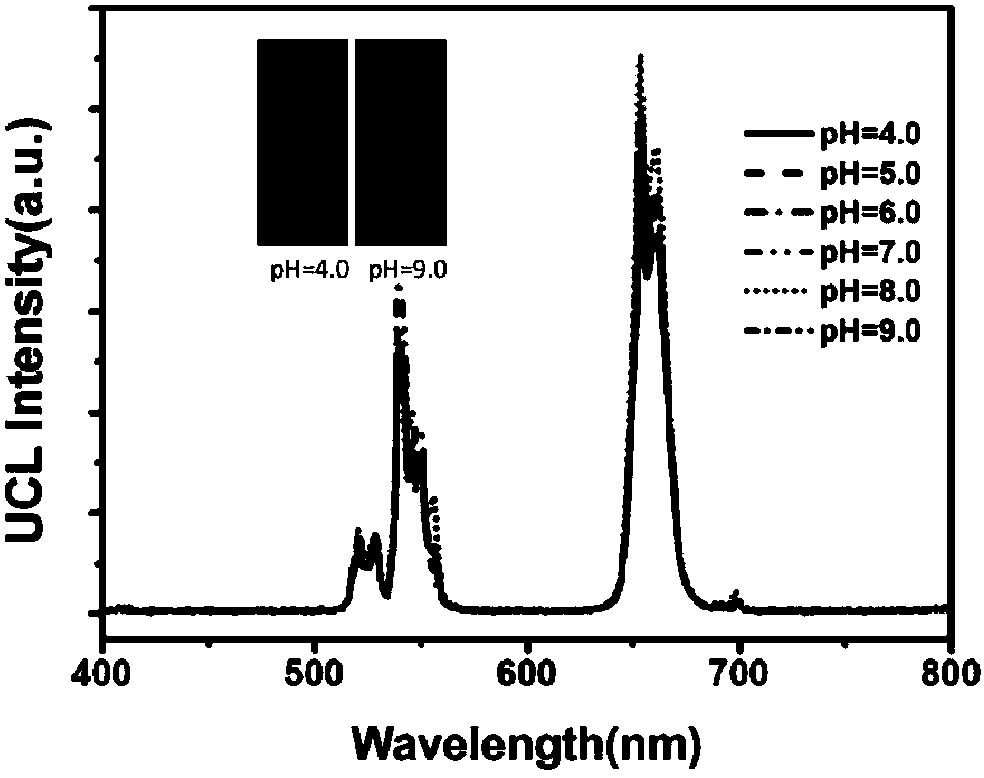

A nanomaterial and ph value technology, applied in the field of nanomaterials, can solve the problem of not having the intelligent response characteristics of the microenvironment, and achieve the effects of good water solubility, strong optical signal, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

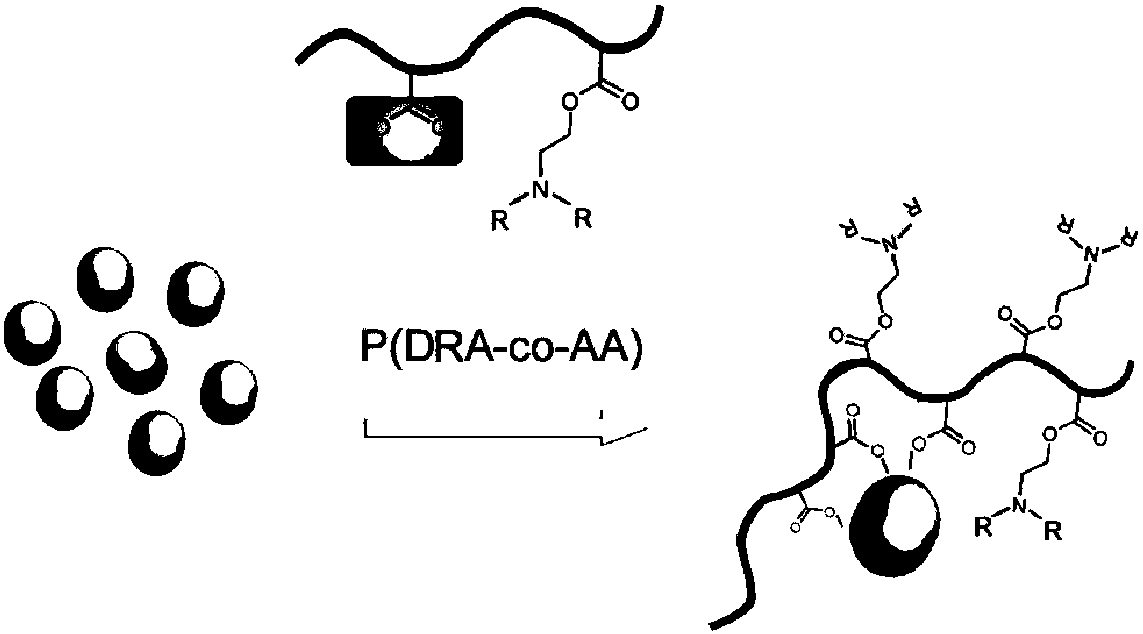

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Upconversion Nanomaterials Responsive to pH Values with a Response Value of pH 5.0

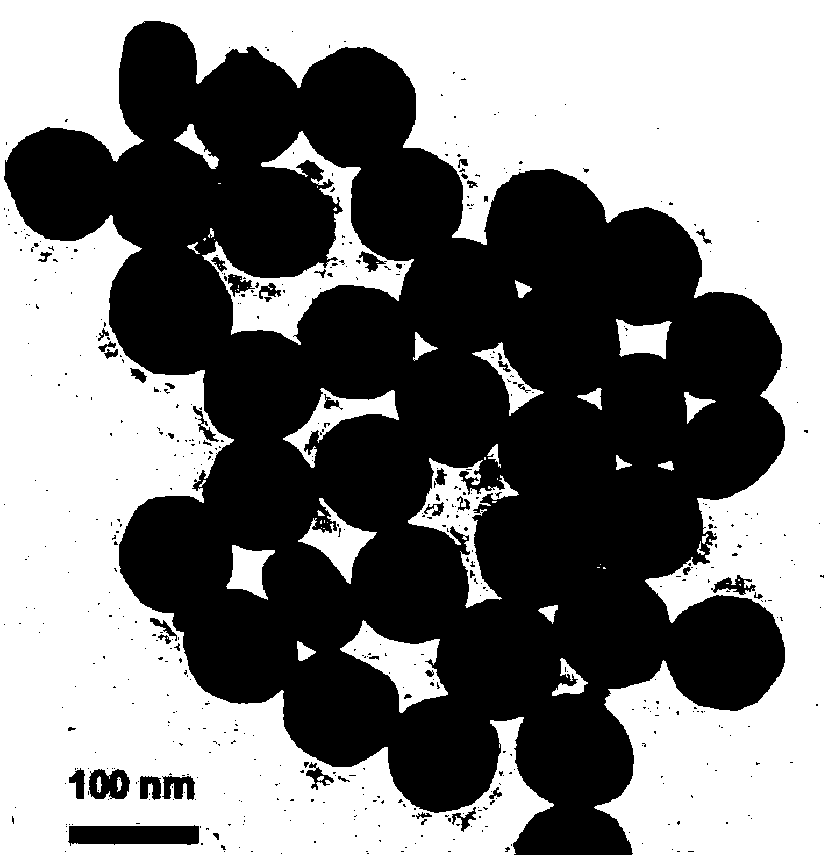

[0035] (1) Weigh LuCl 3 (0.2251g), YbCl 3 (0.0503g) and ErCl 3 (0.0055g), as well as oleic acid (6mL) and octadecene (15mL), in a three-necked flask at 40°C for vacuum deoxygenation, filled with nitrogen, heated to 70°C and then vacuumed; heated to 120°C, reacted for 40min; Finally, the temperature was raised to 160°C and maintained for 5 minutes, then the temperature was naturally lowered to 40°C; NH was added 4 After F (4mmol) and NaOH (2.5mmol), vacuum deoxidize at 40°C, fill with nitrogen, heat up to 70°C and then vacuum; after reacting at 300°C for 60min, cool down to 40°C naturally; put the reaction solution at 12000r / min Centrifuge at a rotating speed, pour off the supernatant, add cyclohexane and ethanol with a volume ratio of 1:1, and ultrasonically disperse. The final product is dispersed with 6mL of cyclohexane, packed into a sample bottle, and obtained by tra...

Embodiment 2

[0042] (1) Weigh YCl 3 (0.0976g), YbCl 3 (0.0503g) and ErCl 3 (0.0055g), and oleic acid (6mL) and octadecene (15mL), deoxidized at 40°C, filled with nitrogen, heated to 70°C and then vacuumed; heated to 130°C, reacted for 60min; heated to 160°C and maintained for 10min Cool down naturally to 40°C; add 0.1481g NH 4 F. After 0.1g NaOH, deoxidize at 40°C, fill with nitrogen, heat up to 70°C and then vacuumize; after reacting at 300°C for 60 minutes, cool down to 40°C naturally; centrifuge the reaction solution at 12000r / min, pour it out To the supernatant, add cyclohexane and ethanol at a volume ratio of 1:1, ultrasonically disperse, and disperse the final product with 9 mL of cyclohexane to elute oleic acid to obtain upconversion nanomaterials that can be dissolved in aqueous solution;

[0043] (2) Weigh hydroquinone (0.0494g), triethylamine (4.3382g), N,N'-diethylethyl alcohol (6.2402g) and tetrahydrofuran (50mL) in sequence, and place in a three-necked flask at 56°C Reflux...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com