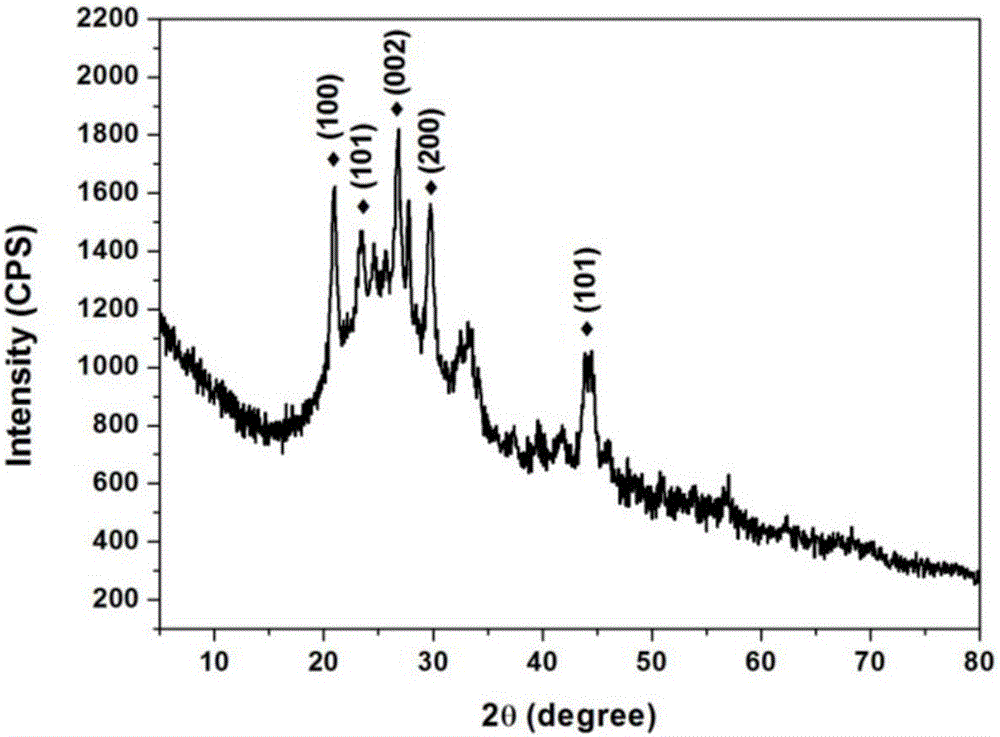

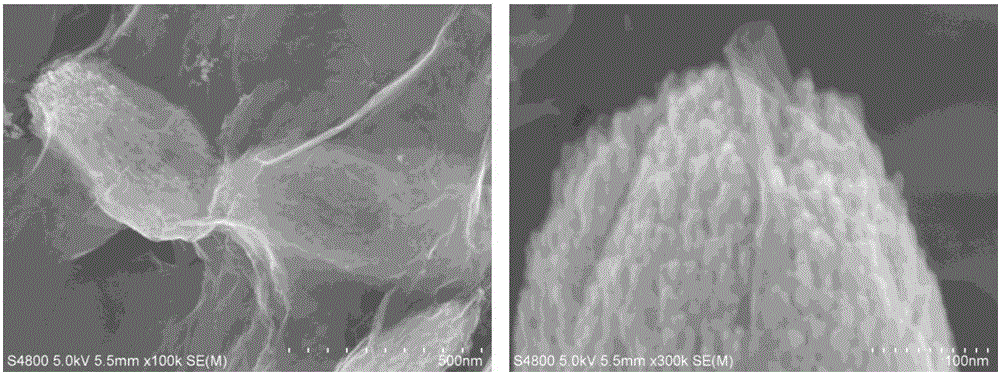

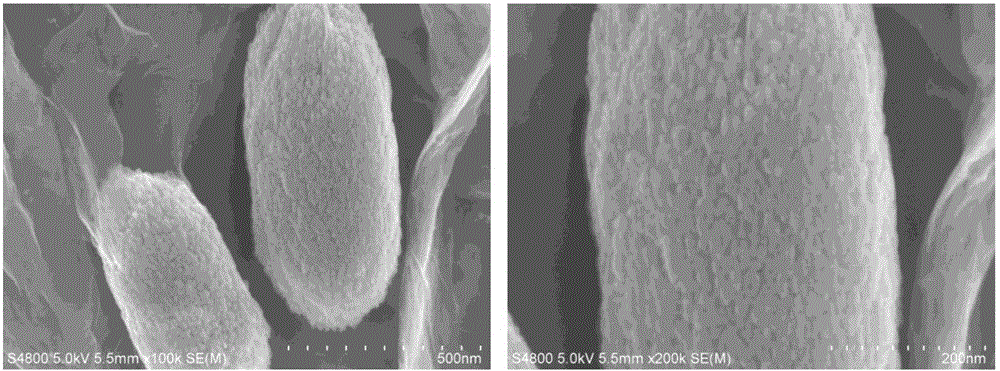

Silkworm-chrysalis-shaped PbS quantum dot/graphene composite material and preparation method thereof

A composite material and graphene technology, applied in nanomaterials and nanometer fields, can solve the problems of difficult desorption of gas molecules, influence on device stability, and long device recovery time, and achieve uniform particle size, low cost, and excellent gas sensing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A "chrysalis-like" PbS quantum dot / graphene composite material is prepared by the following method:

[0027] (1) Graphene oxide is added in 20mL ethylene glycol, utilizes mechanical agitation and ultrasound to disperse graphene oxide completely and evenly in ethylene glycol, forms graphene oxide-ethylene glycol dispersion liquid (concentration of graphene oxide is 0.6wt%);

[0028] (2) Add 1.0 mmol of lead nitrate powder to the graphene oxide-ethylene glycol dispersion, and mechanically stir for 10 to 30 minutes to completely dissolve the lead nitrate powder to obtain the lead nitrate-graphene oxide-ethylene glycol dispersion;

[0029] (3) Dissolve 2.5mmol of sodium sulfide completely in 5mL of ethylene glycol solution, and stir mechanically for 5-10 minutes to form a sodium sulfide-ethylene glycol solution;

[0030] (4) Ultrasonic the lead nitrate-graphene oxide-ethylene glycol dispersion, and at the same time slowly drop the sodium sulfide-ethylene glycol solution dr...

Embodiment 2

[0034] A "chrysalis-like" PbS quantum dot / graphene composite material is prepared by the following method:

[0035] (1) Graphene oxide is added in 20mL ethylene glycol, utilizes mechanical agitation and ultrasound to disperse graphene oxide completely and evenly in ethylene glycol, forms graphene oxide-ethylene glycol dispersion liquid (concentration of graphene oxide 0.1wt%);

[0036] (2) Add 1.0 mmol of lead nitrate powder to the graphene oxide-ethylene glycol dispersion, and mechanically stir for 10 to 30 minutes to completely dissolve the lead nitrate powder to obtain the lead nitrate-graphene oxide-ethylene glycol dispersion;

[0037] (3) Dissolve 1.25 mmol of sodium sulfide completely in 5 mL of ethylene glycol solution, and stir mechanically for 5 to 10 minutes to form a sodium sulfide-ethylene glycol solution;

[0038] (4) Ultrasonic the lead nitrate-graphene oxide-ethylene glycol dispersion, and at the same time slowly drop the sodium sulfide-ethylene glycol solution...

Embodiment 3

[0042] A "chrysalis-like" PbS quantum dot / graphene composite material is prepared by the following method:

[0043] (1) Graphene oxide is added in 20mL ethylene glycol, utilizes mechanical agitation and ultrasound to disperse graphene oxide completely and evenly in ethylene glycol, forms graphene oxide-ethylene glycol dispersion liquid (concentration of graphene oxide is 2.0wt%);

[0044] (2) Add 1.0 mmol of lead nitrate powder to the graphene oxide-ethylene glycol dispersion, and mechanically stir for 10 to 30 minutes to completely dissolve the lead nitrate powder to obtain the lead nitrate-graphene oxide-ethylene glycol dispersion;

[0045] (3) Dissolve 0.25 mmol of sodium sulfide completely in 5 mL of ethylene glycol solution, and stir mechanically for 5 to 10 minutes to form a sodium sulfide-ethylene glycol solution;

[0046] (4) Ultrasonic the lead nitrate-graphene oxide-ethylene glycol dispersion, and at the same time slowly drop the sodium sulfide-ethylene glycol solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com