Improved clamping structure for vehicle steering pipe string

A steering column and automobile technology, applied to the steering column and the steering control installed on the car, etc., can solve the problems such as the large adjustment force of the steering column, the inability to ensure the lock of the handle, and the inability to completely separate the rack, etc., to achieve Low processing cost, avoid tooth-to-tooth phenomenon, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in conjunction with the accompanying drawings.

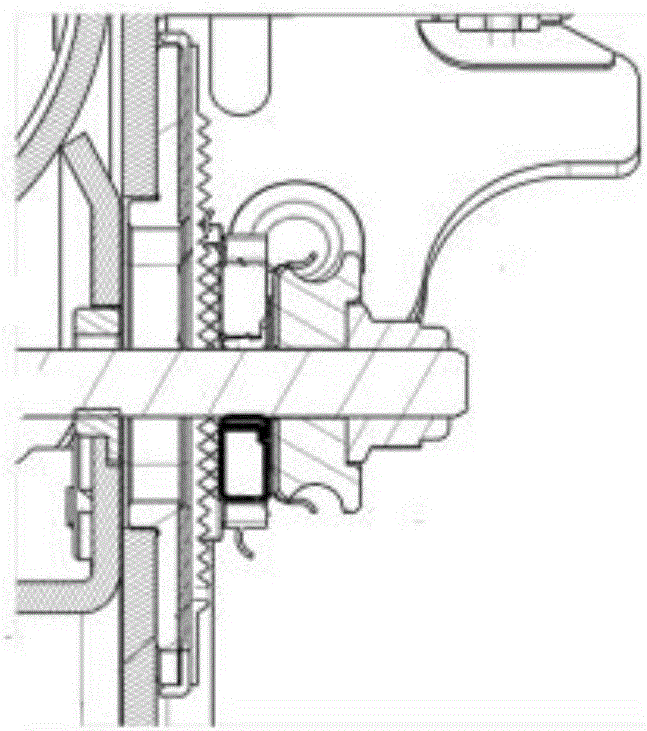

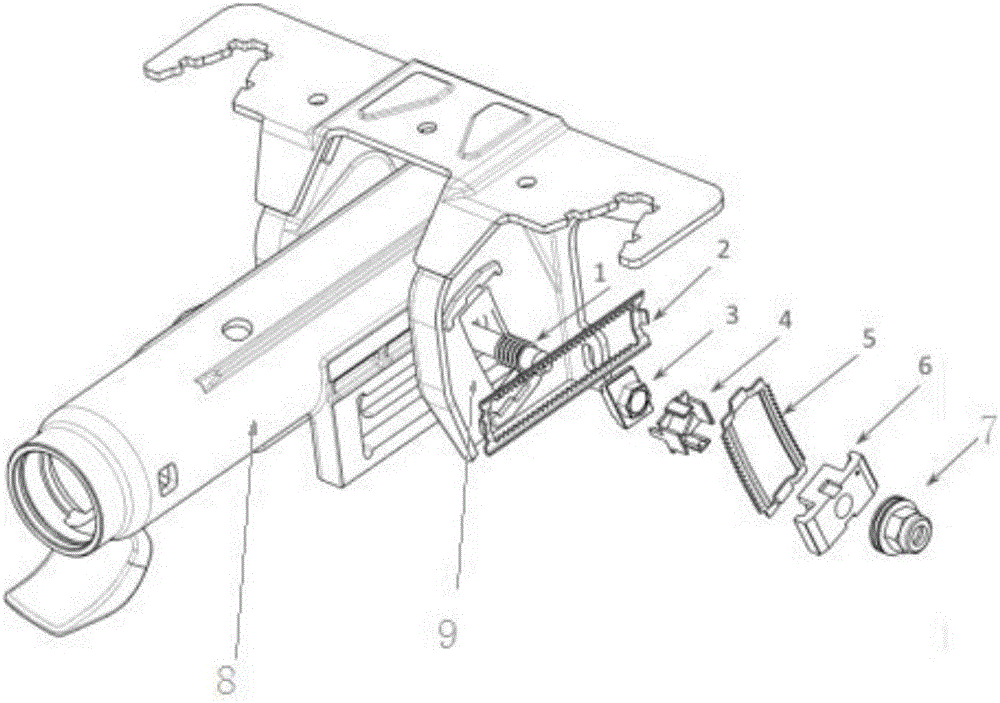

[0016] see figure 2 , the present invention designs an improved automobile steering column clamping structure, comprising: an upper column 8, a U-shaped frame 9, a handle spring 1, the outer side of the upper column 8 is provided with a U-shaped frame 9, and the handle The spring 1 penetrates the upper pipe column 8 and the U-shaped frame 9 from one side of the upper pipe column 8, and the penetrating end of the handle spring 1 is provided with an axial spring rack 2, and a shaft is fixed in front of the axial spring rack 2. To the rack 3, the front of the axial rack 3 is provided with a right radial soft limiter 4, the right radial soft limiter 4 is provided with a radial spring rack 5, and the radial spring rack 5 is clamped with a The radial rack 6 is provided with a tightening nut 7 in front of the radial rack 6; the two ends of the radial spring rack 5 and the U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com