Arc plate zoom adjustable shrinkage cavity used for coal-fired power plant primary air pipe and work method thereof

A plate scaling type, coal-fired power plant technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of easy accumulation of pulverized coal, failure of adjustment effect, shortened service life, etc., to eliminate pulverized coal Accumulation zone, throttling effect is moderate, reducing the effect of regulating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0024] Example.

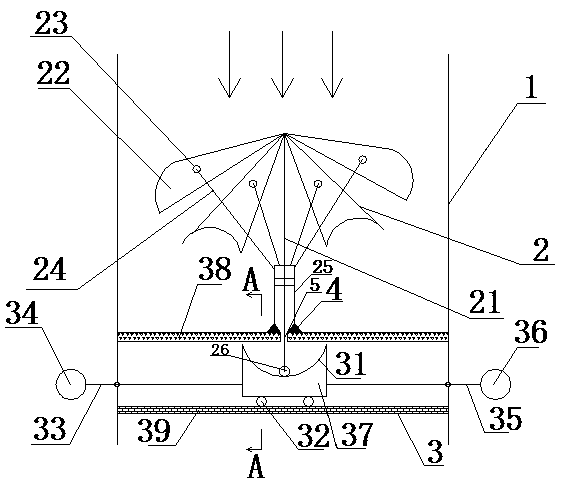

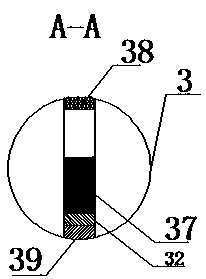

[0025] see Figure 1 to Figure 2 , the arc-shaped plate zoom-type adjustable shrinkage hole used in the primary air duct of a coal-fired power plant in this embodiment includes a zoom-type adjustable shrinkage hole mechanism 2 and an actuator 3, and the zoom-type adjustable shrinkage hole mechanism 2 is located in the primary wind Inside the pipe 1, and the zoom-type adjustable shrinkage mechanism 2 is in contact with the actuator 3; the zoom-type adjustable shrinkage mechanism 2 includes a lifting link 21, a triangular arc plate 22, a connecting buckle 23, a connecting rod 24, and a sleeve 25 And adjusting cam 26, the tip of triangular arc plate 22 links to each other with the upper end of liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com