Reducing spherical plugging device

A occluder and variable-diameter technology, which is applied in the field of variable-diameter spherical occluders, can solve problems such as poor sealing of pipeline occluders and resistance in the recovery process, and achieve convenient operation, reduced resistance, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

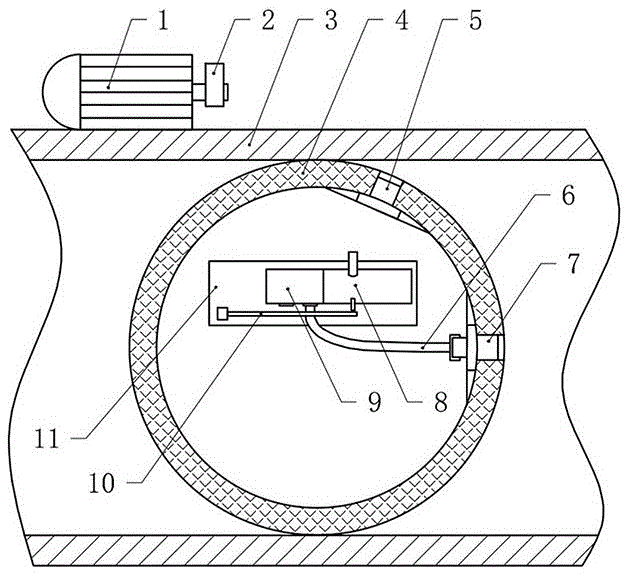

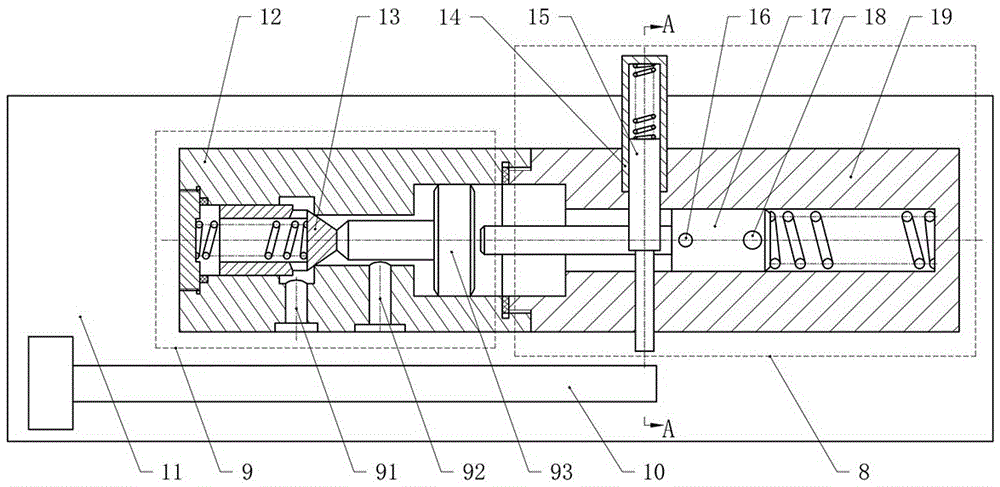

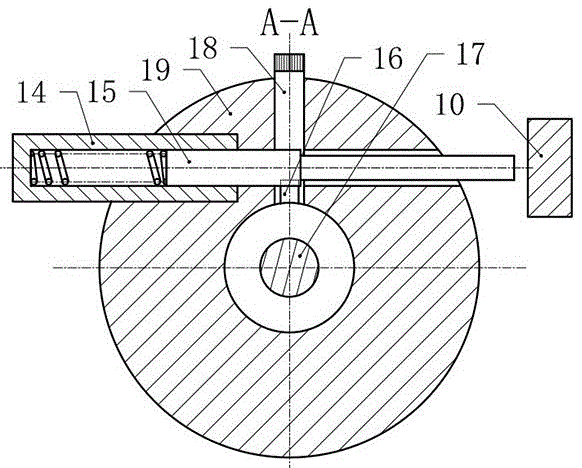

[0018] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below Figure 1~4 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0019] The housing 4 is a rubber spherical shell, and an injection joint 7 is installed in the housing 4 . The injection joint 7 communicates with the outside of the housing 4 , and liquid is injected into the housing 4 through the injection joint 7 . The casing 4 is provided with a vent hole 5, which is arranged above the installation position of the casing 4. When the liquid is injected into the casing 4 through the injection joint 7, the air in the casing 4 passes through the vent hole 5 Discharge, close the air vent 5 after the air is discharged.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com