Y-shaped groove back-chipping-free submerged-arc welding technology for moderately thick plate in boiler and pressure container

A pressure vessel and welding process technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large weld metal filling, low production efficiency, serious environmental pollution, etc., achieve stable welding quality, and improve production The effect of high efficiency and weld qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

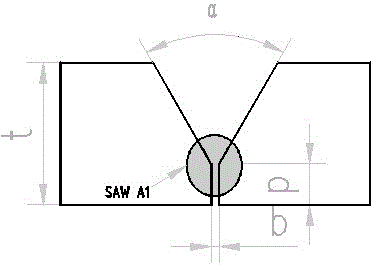

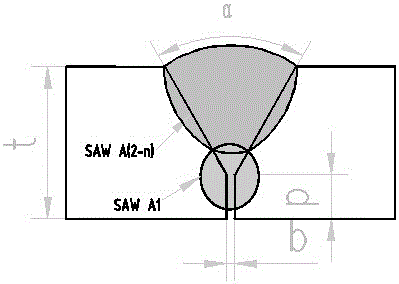

[0021] In this embodiment, the welding process of Y-shaped groove submerged arc welding of medium and thick plates in the longitudinal circular seam of the medium and thick plates of boilers and pressure vessels without clearing the root includes the steps:

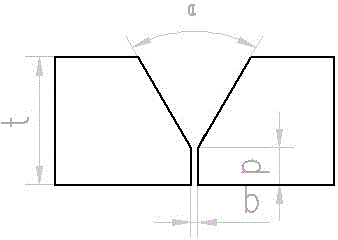

[0022] Cutting and assembly steps before welding, the medium and thick plate cylinder is machined or flame cut according to the thickness of the plate to form a Y-shaped groove;

[0023] In one embodiment, the pre-welding cutting and assembling steps further include a spot welding positioning process, and the spot welding positioning adopts semi-automatic gas shielded welding to perform spot welding on the post-welding side, and uses a ¢1.0 solid-core welding wire.

[0024] figure 1 A schematic diagram of cutting and assembly before welding is disclosed. The process of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com