Milling machine used for automobile large-plane die

A large plane and milling machine technology, which is applied in the field of milling machines for automobile large plane molds, can solve the problems of low processing efficiency, high labor intensity, and slow milling speed, and achieve the effects of improving work efficiency, reducing labor intensity, and fast milling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

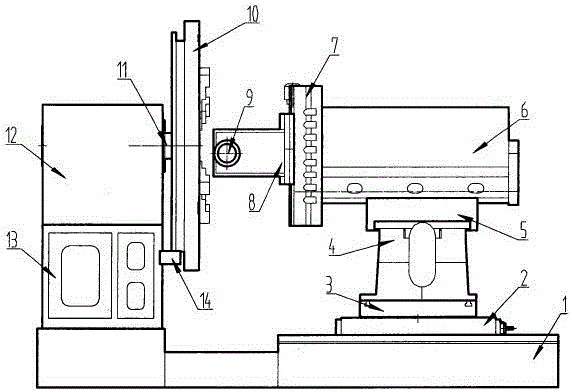

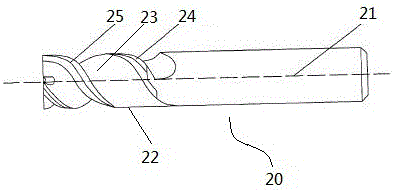

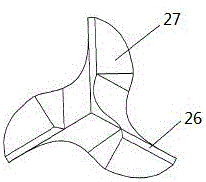

[0016] like figure 1 Shown, a kind of milling machine that is used for automobile large plane mould, comprises milling machine base 1, and described milling machine base 1 is provided with stroke slide plate 2; A milling cutter three-dimensional device is provided; the milling cutter three-dimensional device includes a first guide rail 4, a second guide rail 6, a third guide rail 7, and a milling cutter spindle 9, and the first guide rail 4 is fixedly mounted on the rotary disk 3; Two guide rails 6 are fixedly installed on the first guide rail 4, and the third guide rail 7 is fixedly installed on the second guide rail 6; the milling cutter spindle 9 is fixedly arranged on the third guide rail 7, and a milling cutter is installed on the milling cutter spindle 9 20; the milling machine base 1 is also provided with a workbench 10, and the workbench 10 is set corresponding to the three-dimensional device of the milling cutter; as figure 2 , image 3 As shown, the milling cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com