Composite type artificial dura mater and preparation method

An artificial dura mater and composite technology, applied in medical science, prosthesis, etc., can solve the problems of scarring or wrapping reaction, increase of operation and treatment time, weak biocompatibility and other problems, and achieve the benefit of wound surface Repair, easy industrial preparation, effect of increasing fiber surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) select fibrin and deionized water to prepare hydrogel solution according to the molar ratio of 1:10;

[0030] 2) making a suspension of the fibroblast growth factor and the hydrogel material at a molar ratio of 1:5000;

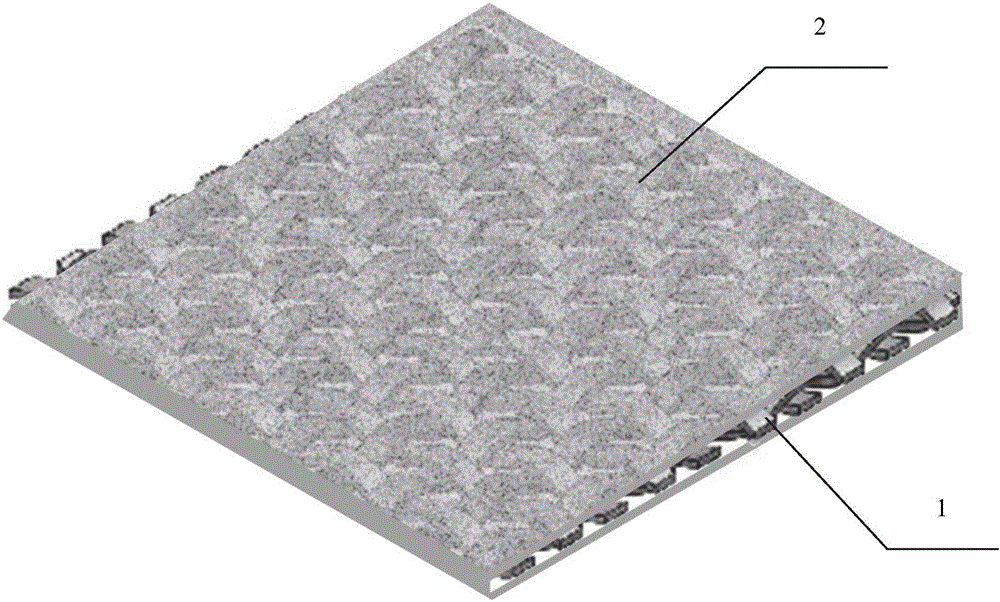

[0031] 3) Place the hydrogel suspension in a film-forming mold to form a film with a thickness of 100 μm, and cure at 4°C for 2 hours;

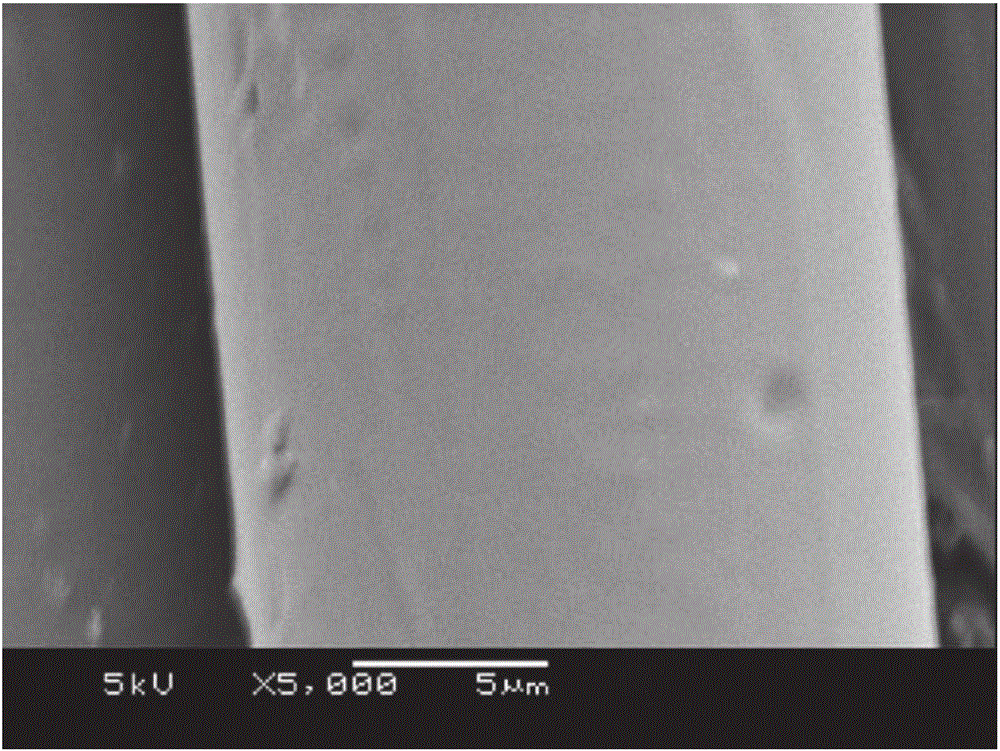

[0032] 4) The braided wire is made of PLA, and the surface is treated with helium plasma, the gas temperature is 90°C, the flow rate is 4L / min, and the treatment time is 4min;

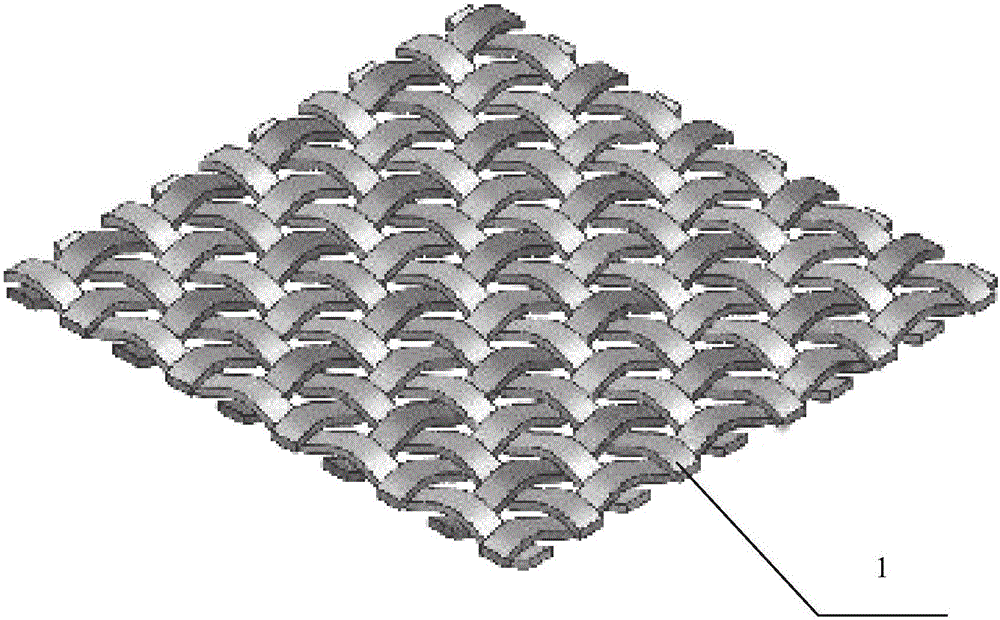

[0033] 5) The braided wire is made of a braided layer using a Hercules braiding process, with a thickness of 500 μm;

[0034] 6) After the braided layer is placed on the cured hydrogel and spread flat, a layer of hydrogel suspension with a thickness of 100 μm is spread on the braided layer, and cured at 4°C for 2 hours;

[0035] 7) Sterilize the artificial dura mater with an irradiation dose of 25kGy.

Embodiment 2

[0037] 1) Select collagen and deionized water to configure hydrogel solution according to the molar ratio of 1:20;

[0038] 2) making a suspension of the fibroblast growth factor and the hydrogel material at a molar ratio of 1:4000;

[0039] 3) placing the hydrogel suspension in a film-forming mold to form a film with a thickness of 200 μm, and curing at 4° C. for 3 hours;

[0040] 4) The braided wire is made of PGA, and the surface is treated with helium plasma, the gas temperature is 100°C, the flow rate is 6L / min, and the treatment time is 6min;

[0041] 5) The braided wire is made of a braided layer using a Hercules braiding process, with a thickness of 1000 μm;

[0042] 6) After the braided layer is placed on the cured hydrogel and paved flat, a layer of hydrogel suspension with a thickness of 200 μm is spread on the braided layer, and cured at 4°C for 3 hours;

[0043] 7) Sterilize the artificial dura mater with an irradiation dose of 28 kGy.

Embodiment 3

[0045] 1) Select collagen and deionized water to configure hydrogel solution according to the molar ratio of 1:20;

[0046] 2) making the vascular endothelial growth factor and the hydrogel material into a suspension according to the molar ratio of 1:4000;

[0047] 3) placing the hydrogel suspension in a film-forming mold to form a film with a thickness of 300 μm, and curing at 6° C. for 3 hours;

[0048] 4) The braided wire is made of PLGA, the surface is treated with oxygen plasma, the gas temperature is 100°C, the flow rate is 8L / min, and the treatment time is 8min;

[0049] 5) The braided wire is made into a braided layer by a two-dimensional triaxial braiding process, with a thickness of 1000 μm;

[0050] 6) After the braided layer is placed on the cured hydrogel and paved flat, a layer of hydrogel suspension with a thickness of 300 μm is spread on the braided layer, and cured at 6° C. for 3 hours;

[0051] 7) Sterilize the artificial dura mater with an irradiation dose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com