Green prickleyash drying method

A kind of green pepper and microwave killing technology, which is used in food science, food preservation, application and other directions. It can solve problems such as long cycle, unhygienic, poor quality and other problems, and achieve the effect of improvement of the finished product rate, saving cost, and high opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

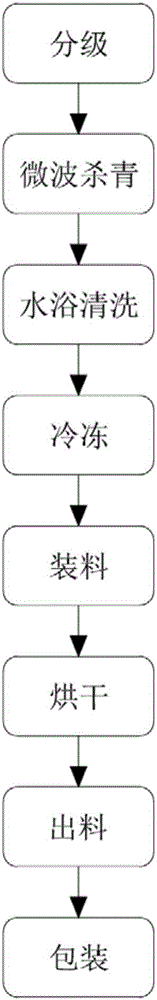

Image

Examples

Embodiment 1

[0022] A method for drying green peppercorns, comprising steps of grading, microwave cleaning, water bath cleaning, freezing, charging, drying, discharging and packaging. The specific steps of the drying method for green peppercorns are as follows:

[0023] S1: Grading: Clean the dirt on the surface of the green pepper and remove the impurities in the root, and then classify it to ensure that it is heated evenly during the forced drying process and the drying conditions are consistent;

[0024] S2: Microwave de-enzyming: Send the graded green pepper to a microwave de-enzyming machine for de-enzyming treatment, wherein the microwave power is 300KW, and the microwave drying temperature is 120°;

[0025] S3: Water-bath cleaning: Put the green pepper after microwave treatment into a water-bath washing machine for cleaning to remove the dirt on the surface of the green pepper. The water temperature in the water-bath washing machine is 30°, and the working time is 10 minutes;

[002...

Embodiment 2

[0032] A method for drying green peppercorns, comprising steps of grading, microwave cleaning, water bath cleaning, freezing, charging, drying, discharging and packaging. The specific steps of the drying method for green peppercorns are as follows:

[0033] S1: Grading: Clean the dirt on the surface of the green pepper and remove the impurities in the root, and then classify it to ensure that it is heated evenly during the forced drying process and the drying conditions are consistent;

[0034] S2: Microwave de-enzyming: Send the graded green pepper to a microwave de-enzyming machine for de-enzyming treatment, wherein the microwave power is 200KW, and the microwave drying temperature is 90°;

[0035] S3: Water-bath cleaning: Put the green pepper after microwave treatment into a water-bath washing machine for cleaning to remove the dirt on the surface of the green pepper. The water temperature in the water-bath washing machine is 34°, and the working time is 12 minutes;

[0036...

Embodiment 3

[0042] A method for drying green peppercorns, comprising steps of grading, microwave cleaning, water bath cleaning, freezing, charging, drying, discharging and packaging. The specific steps of the drying method for green peppercorns are as follows:

[0043] S1: Grading: Clean the dirt on the surface of the green pepper and remove the impurities in the root, and then classify it to ensure that it is heated evenly during the forced drying process and the drying conditions are consistent;

[0044] S2: Microwave de-enzyming: Send the graded green pepper to a microwave de-enzyming machine for de-enzyming treatment, wherein the microwave power is 150KW, and the microwave drying temperature is 110°;

[0045] S3: Water-bath cleaning: Put the green pepper after microwave treatment into a water-bath washing machine for cleaning to remove the dirt on the surface of the green pepper. The water temperature in the water-bath washing machine is 40°, and the working time is 15 minutes;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com