Low-voltage high-power driving circuit for servo motor control

A drive circuit and servo motor technology, applied in the field of excitation or armature current control, output power conversion device, electrical components, etc., can solve difficult problems and achieve light weight and low power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

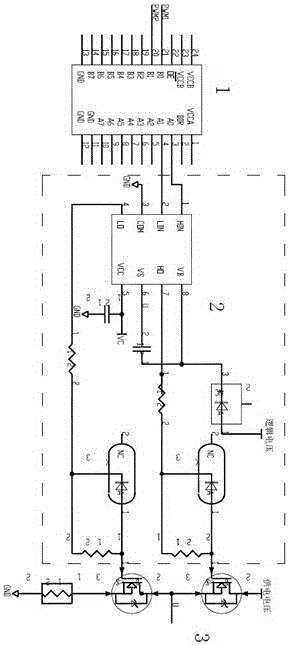

[0014] A low-voltage high-power drive circuit for servo motor control, including a signal isolation circuit, a gate-level drive circuit, and a MOSFET tube circuit, wherein the input of the signal isolation circuit is connected to a PWM signal, and the output of the signal isolation circuit is connected to the gate The input ends of the drive circuit are connected, the output end of the gate-level drive circuit is connected with the input end of the MOSFET tube circuit, the output end of the MOSFET tube circuit is connected with the servo motor, and the servo motor is driven by controlling the MOSFET tube circuit.

[0015] A driver chip is provided in the gate-level drive circuit, and the driver chip adopts the IR2108 gate-level driver chip of IR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com