High heat radiation composite cable

A composite cable and high heat dissipation technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor anti-pressure protection performance, reduced work efficiency, and difficulty in pulling out cable cores, etc., to achieve increased pressure resistance and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

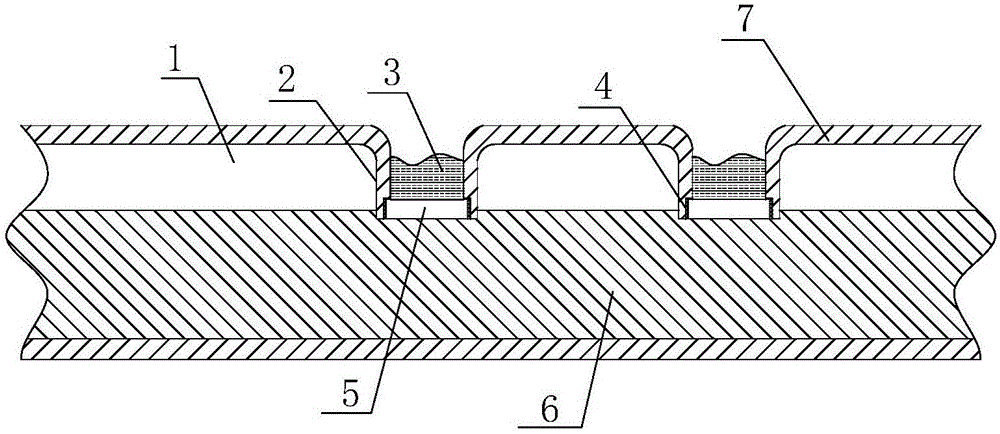

[0015] Such as figure 1 As shown, the high heat dissipation composite cable includes the outermost PVC protective layer 7 and the cable 6 installed in the PVC protective layer 7, and more than one convex portion 2 is evenly distributed on one end surface of the PVC protective layer 7, The protruding part 2 extends to one side of the cable 6 and is pressed against one end face of the cable 6. The upper end face of the protruding part 2 is open, and an accommodating cavity is formed at the opening end, and the material of the protruding part 2 and the PVC protective layer 7 is the same;

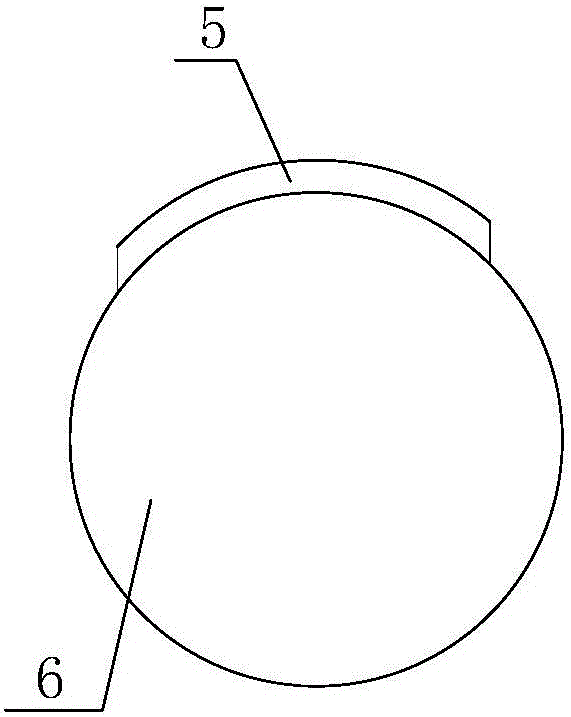

[0016] The lower end surface of the convex part 2 is provided with an arched opening, and the arched opening is sealed by an arched bottom plate 5. 6 The upper end face is in sealing contact.

[0017] In this embodiment, the lower end surface of the arched bottom plate 5 and the lower end surface of the convex part 2 are provided with an arc-shaped groove parallel to the cable, and the arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com