System and method used for integrating routine tests of railway vehicles

A rail vehicle and rail technology, applied in the system and experimental fields, can solve the problems of increasing use and maintenance costs, consuming manpower and manpower, and increasing labor costs, and achieves the effect of saving hoisting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 100% low-floor trams on the through-line process and test flow,

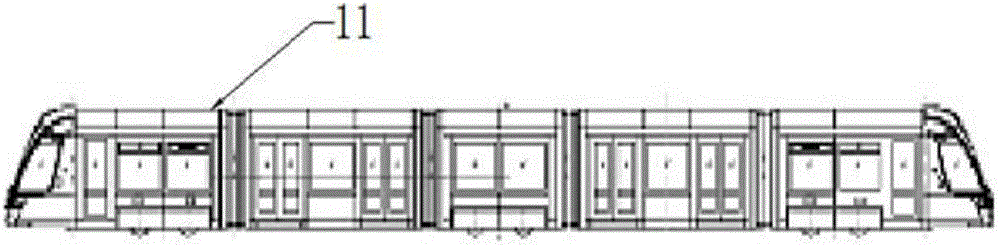

[0045] refer to figure 2 , 100% low-floor tram marshalling method: =Mc1+F1+Tp+F2+Mc2=Mc1, where Mc2 is the motor car module where the motor car bogie and cab are installed; Tp is the trailer where the pantograph and trailer bogie are installed Modules; F1 and F2 are suspension car body modules; F1 and F2 are suspension car body modules, + is a windshield sealing hinge structure between units, and = is a semi-automatic coupler (foldable type) at both ends.

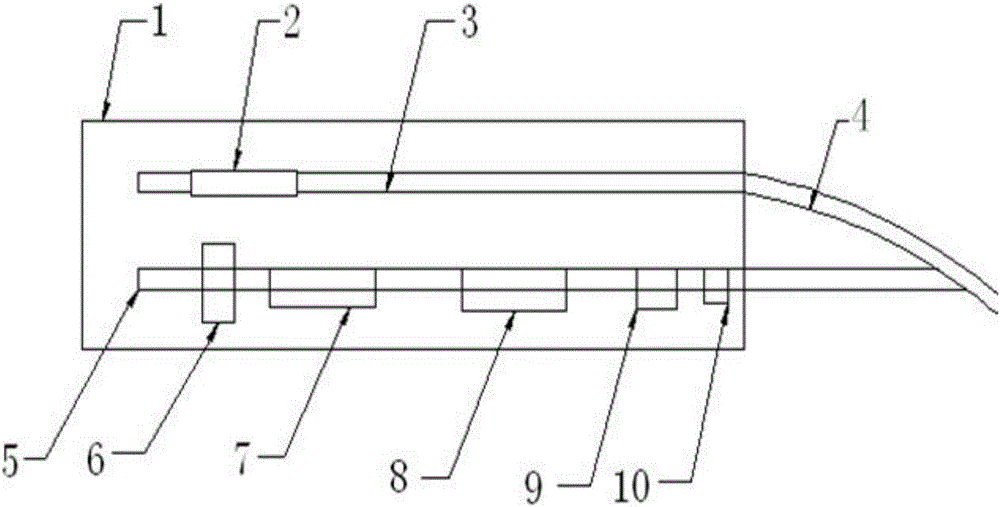

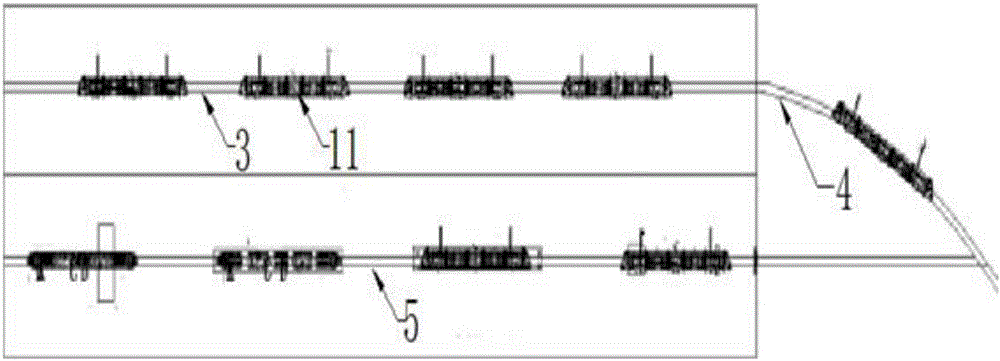

[0046] refer to image 3 , 100% low-floor tram 5 modules each single car (Mc1, F1, Tp, F2, Mc2) completes the connection of the car body and the bogie in the single-car drop-off adjustment ditch 7 shown in the figure, that is, the single-car drop-off process. After the single-vehicle landing is completed, use the single-vehicle transfer trolley to the right to transport the 5-module single-vehicle to the illustrated complete-vehicle coupling ditch ...

Embodiment 2

[0048] 70% low-floor trams on the through-line process and test circulation, refer to Figure 4 , train marshalling mode: =Mc+Tp+Mc=Mc, wherein, Mc is the motor car module that installs the motor car bogie and driver's cab, Tp is the trailer module that installs pantograph and trailer bogie, + is the windshield seal between the units Hinged structure = being semi-automatic couplers (foldable type) at both ends.

[0049] refer to figure 2 , 70% low-floor tram process and test circulation process are completely consistent with 100% low-floor tram circulation.

Embodiment 3

[0051] Process and test circulation of urban rail subway trains on the through line

[0052] refer to Figure 5 , train marshalling mode: =Tc*Mp*M*M*Mp*Tc=, wherein = is a semi-automatic coupler, * is a semi-permanent drawbar, Tc is a trailer with a cab, M is a motor car without a cab, and Mp is no Motor car with pantograph in driver's cab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com