Intelligent pipeline climbing robot

A technology of crawling robots and intelligent pipes, which is applied to special pipes, pipe components, mechanical equipment, etc., and can solve problems such as bulky, difficult to process, and huge machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

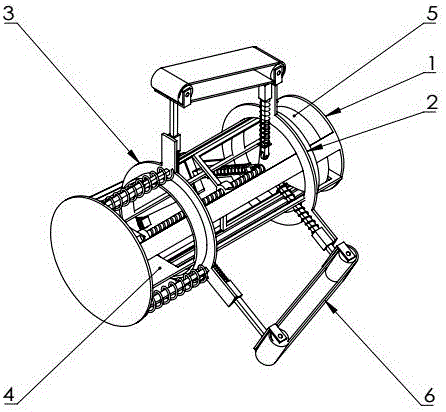

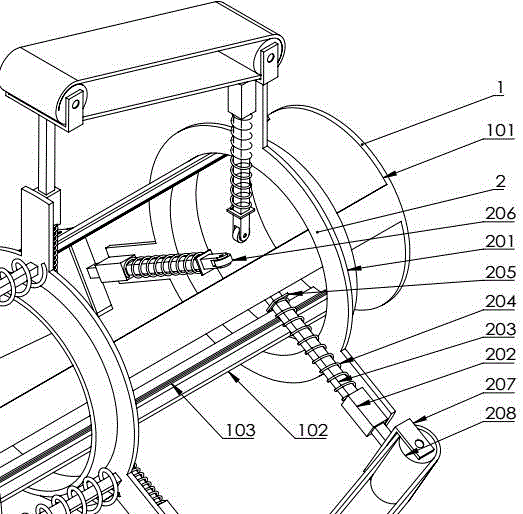

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an intelligent pipeline crawling robot includes a frame 1, a driving device 2, an auxiliary device 3, a screw mechanism 4, a tapered transmission member 5, and three crawlers 6, and is characterized in that: the frame 1 includes 2 One end cover 101, three connecting frames 102, and three conical slide rails 103, the connecting frame 102 is fixedly installed between the two end covers, and the inner centerlines of the three connecting frames 102 are provided with conical slide rails 103; the driving device 2 includes a first fixing frame 201, three first square sleeves 202, three first sliding rods 203, three first springs 204, three first spring fixing frames 205, and three Pulley 206, 3 first wheel fixing frames 207, 3 first wheels 208, the first fixing frame 201 is fixedly installed on the 3 connecting frames 102 near the position of the right end cover 101, the first square The sleeve 202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com