A thimble type anti-air valve eccentric wear gas distribution mechanism and its use method

A technology of gas distribution mechanism and anti-air valve, which is applied in the direction of valve details, valve devices, mechanical equipment, etc., can solve the problems of lack of guiding devices, damage to parts, and easy deviation, so as to avoid partial wear of air valves and reduce Friction, to prevent the effect of eccentric wear of the valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

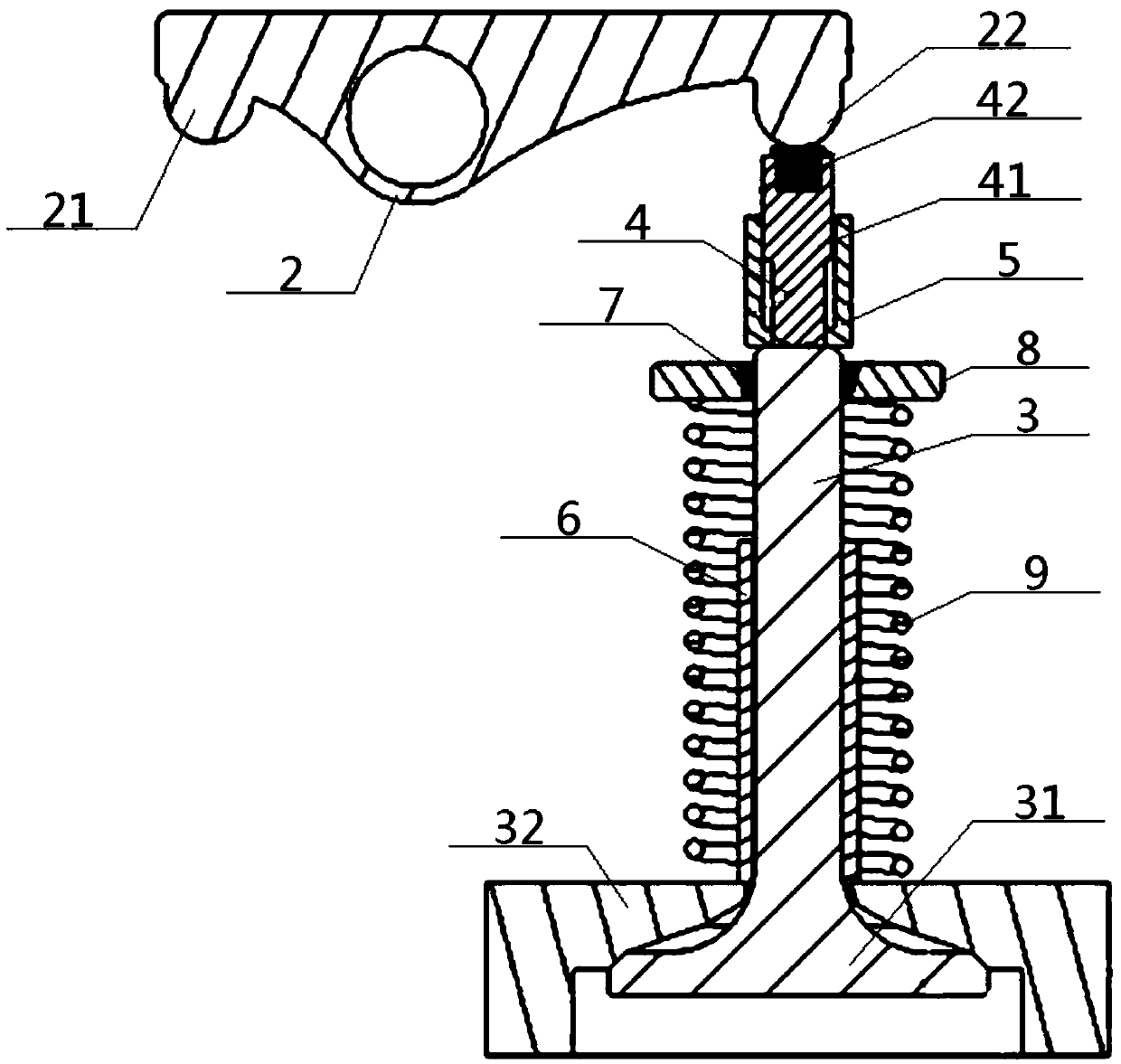

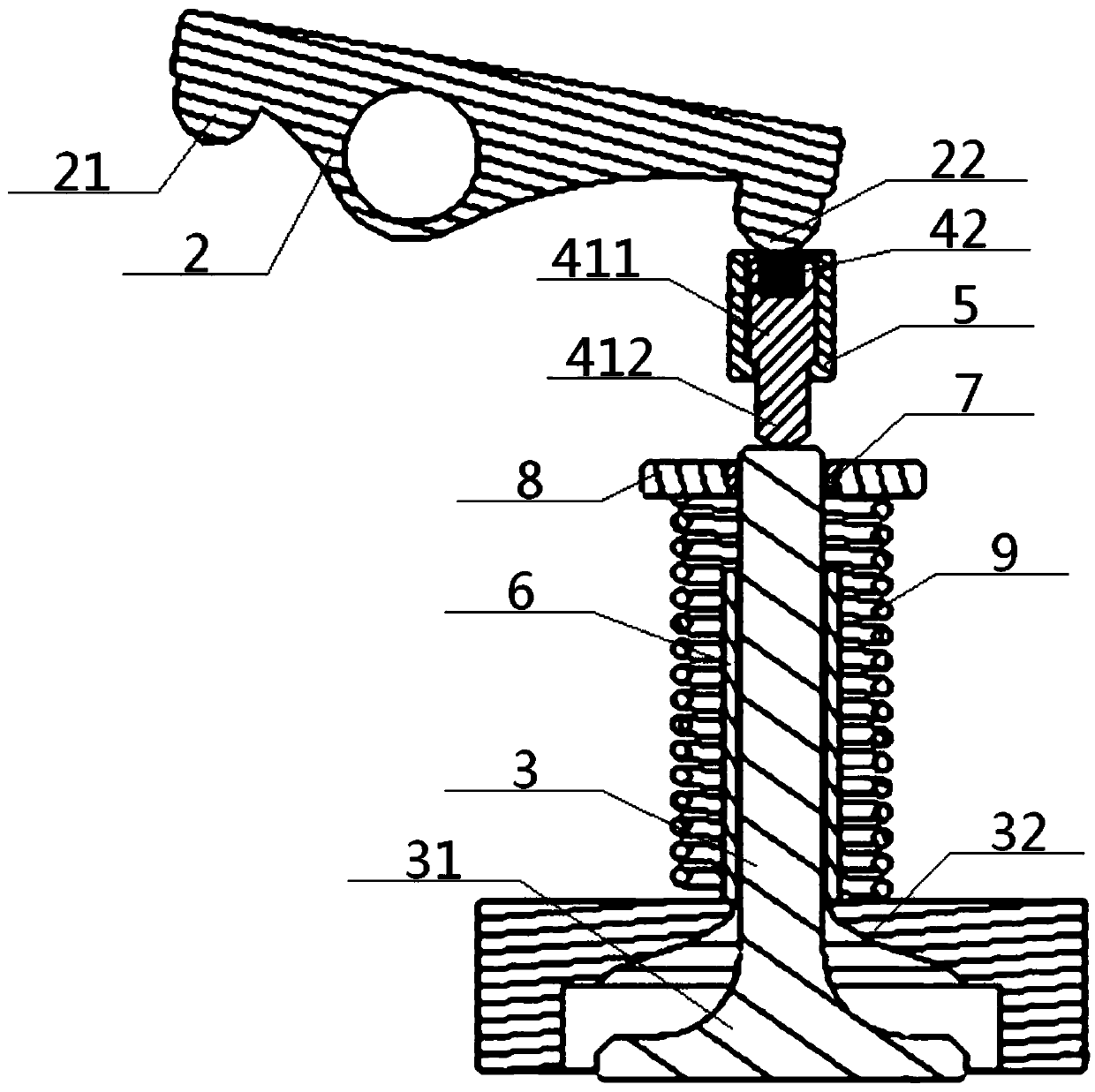

[0047] see Figure 1 to Figure 5 , a thimble type anti-air valve eccentric wear distribution mechanism, including rocker arm 2, rotating shaft 23, valve stem 3, valve head 31, thimble structure 4, structure seat 5 and valve guide 6, the rocker arm The middle part of 2 moves up and down in an arc around the rotating shaft 23 at its bottom, and the outer end of the rocker arm 2 cooperates with the upper top device 1 for upward movement; the inside of the structural seat 5 is provided with a structural cavity 51, and the structural seat 5 The bottom of the bottom is provided with a cavity rod hole 52 communicating with the structural cavity 51. The thimble structure 4 includes a needle valve body 41, a needle valve 42 and an elastic material 43. The needle valve body 41 includes an upper valve body 411 and a lower valve body 412. , the top of the upper valve body 411 is provided with a valve groove 413 to be connected with the needle valve 42, the valve groove 413 and the needle ...

Embodiment 2

[0051] Basic content is the same as embodiment 1, the difference is:

[0052] The needle valve 42 is a T-shaped structure, including an outer horizontal part 421 and an inner vertical part 422 connected vertically, the outer wall of the inner vertical part 422 is wrapped in the inner part of the elastic material 43, and the outer part of the elastic material 43 is connected with the valve groove. The inner walls of 413 are connected, and the outer transverse portion 421 covers the valve groove 413 and the top of the elastic material 43 . The elastic material 43 is a hollow cylindrical structure, the bottom of the inner vertical part 422 and the lower valve body 412 are conical structures, and there is an inner gap 44 between the bottom of the inner vertical part 422 and the elastic material 43, There is an outer gap 53 between the bottom end of the lower valve body 412 and the cavity rod hole 52 .

Embodiment 3

[0054] Basic content is the same as embodiment 1, the difference is:

[0055] Structurally—the air distribution mechanism of the anti-air valve eccentric wear also includes a lock block 7, a spring seat 8 and a spring 9. The middle part of the spring seat 8 is fixedly connected with the lock block 7 embedded in it, and the lock block 7 and the The air valve stem 3 passing through the bottom is fixedly connected, the top of the air valve stem 3 is matched with the bottom of the lower valve body 412 for downward movement, and the bottom end of the air valve stem 3 passes through the lock block 7, the spring 9, and the cylinder head 32 in turn. After that, it is vertically connected with the valve head 31; on the valve rod 3, a spring 9 is set on the outside of the position between the spring seat 8 and the cylinder cover 32, and the top of the spring 9 is fixedly connected with the bottom surface of the spring seat 8, and the spring The bottom of 9 is fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com