Intrastratal explosive fracturing ignition ball and fracturing construction method

A construction method and ignition ball technology, which are used in earth-moving drilling, production of fluids, wellbore/well components, etc., to shorten the dwell time, reduce damage, and reduce injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

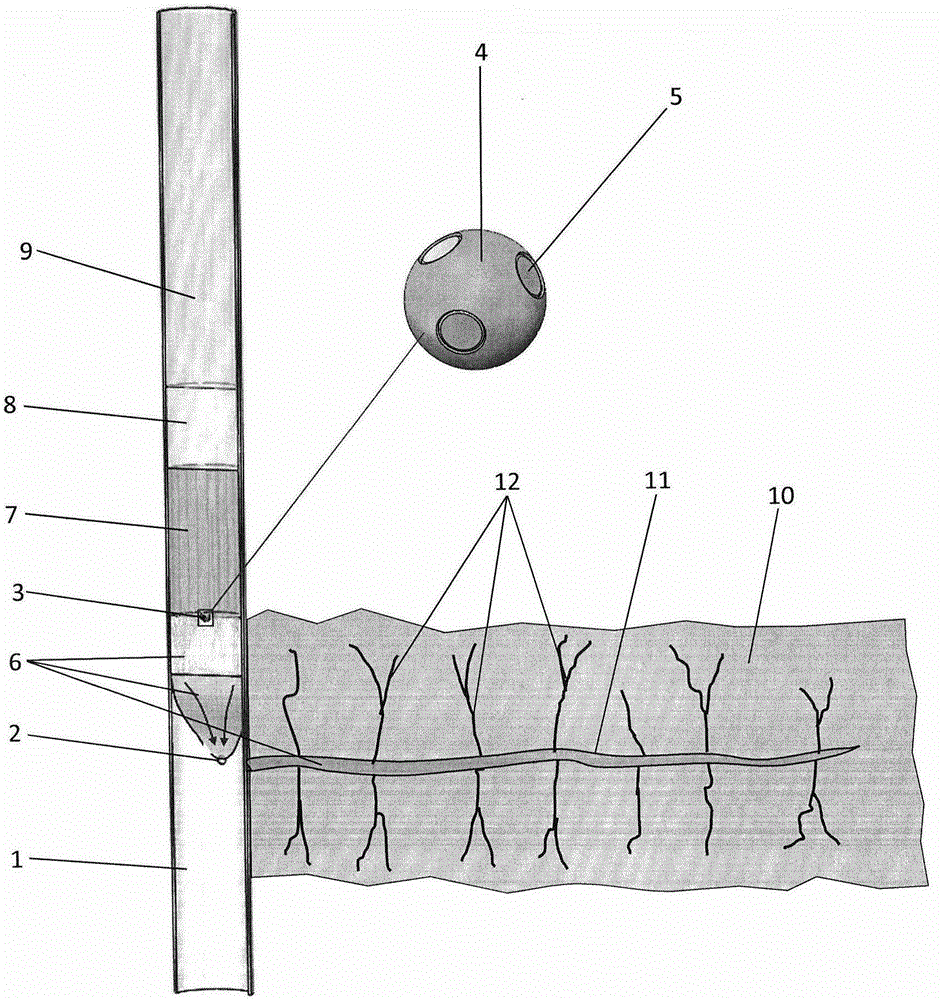

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0022] Such as figure 1 Shown is the schematic diagram of the construction method of explosive fracturing in the middle layer of the present invention, and specific implementation includes the following contents:

[0023] A number of perforation holes 2 are formed in the reservoir casing 1 by means of perforation completion to prepare for fracturing;

[0024] The implementation of hydraulic fracturing can cooperate with the end sand screen technology to form a hydraulic fracture 11 with a certain fracture length and fracture width inside the reservoir 10;

[0025] After the hydraulic fracturing is completed, pump 8 slugs of spacer fluid, 6 slugs of large liquid explosives into the wellbore in sequence, put in ignition balls 3 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com