Eco-friendly composite material and production method thereof

A composite material and production method technology, applied in the field of composite materials, can solve the problems of high production cost, complex formula, environmental pollution, etc., and achieve the effect of improving air quality and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

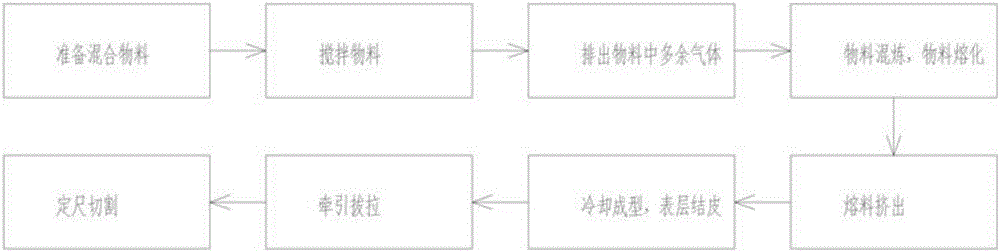

[0055] as attached figure 1 Shown, a kind of production method of the environmental protection composite material described in claim 1 comprises the following steps:

[0056] 1) Prepare the mixed material, which includes: 40-60 parts of PVC, 10-60 parts of calcium powder, 0.1-40 parts of carbon powder, 1.5-4 parts of stabilizer, 1-5 parts of negative oxygen Ion powder, 0.1-5 parts of photo-oxygen catalyst, 0.2-1 parts of flame retardant, 0.1-5 parts of toughening agent, 0.1-3 parts of modifier and 1-15 parts of plant fiber powder;

[0057]2) Stir the material, use a mixer to stir the material, and the stirring time is 35-50 minutes;

[0058] 3) Exhaust the excess gas in the material, and use the vacuum pump to extract the excess gas in the mixer. The vacuum degree in the mixer is 0.07-0.09MPa;

[0059] 4) Material mixing, material melting, the melting temperature of the material is 170-190 ° C, using the mixing section of the foaming twin-screw extruder for material mixing, ...

Embodiment 2

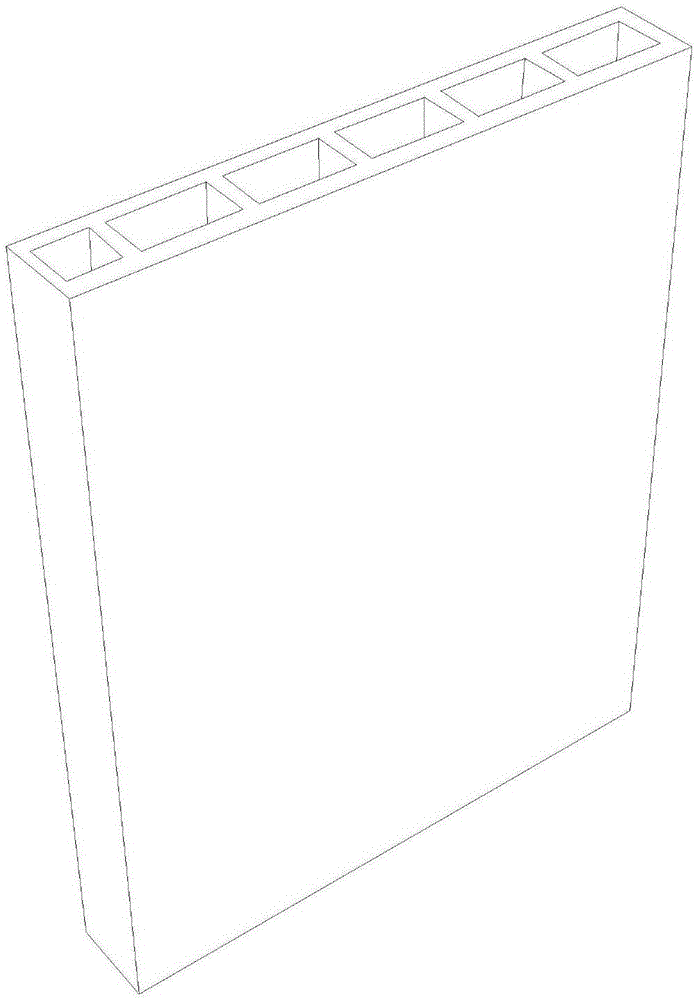

[0074] as attached figure 2 As shown, after step 5) and before step 6), vacuum pumping of the molten material is also included. Except for this, other steps and implementation methods are the same as in Example 1.

[0075] Through vacuum pumping, the cross-section of the extruded molten material is in the shape of a flute. The molding material after this step helps to reduce the weight of the product; at the same time, it can save the molten material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com