Potassium chlorate production equipment and method

A technology of production equipment and production methods, applied in the direction of chloric acid, chlorate, chemical instruments and methods, etc., can solve the problems of acid and alkali waste, achieve the effects of preventing harmful solid waste, increasing crystallization efficiency, and quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

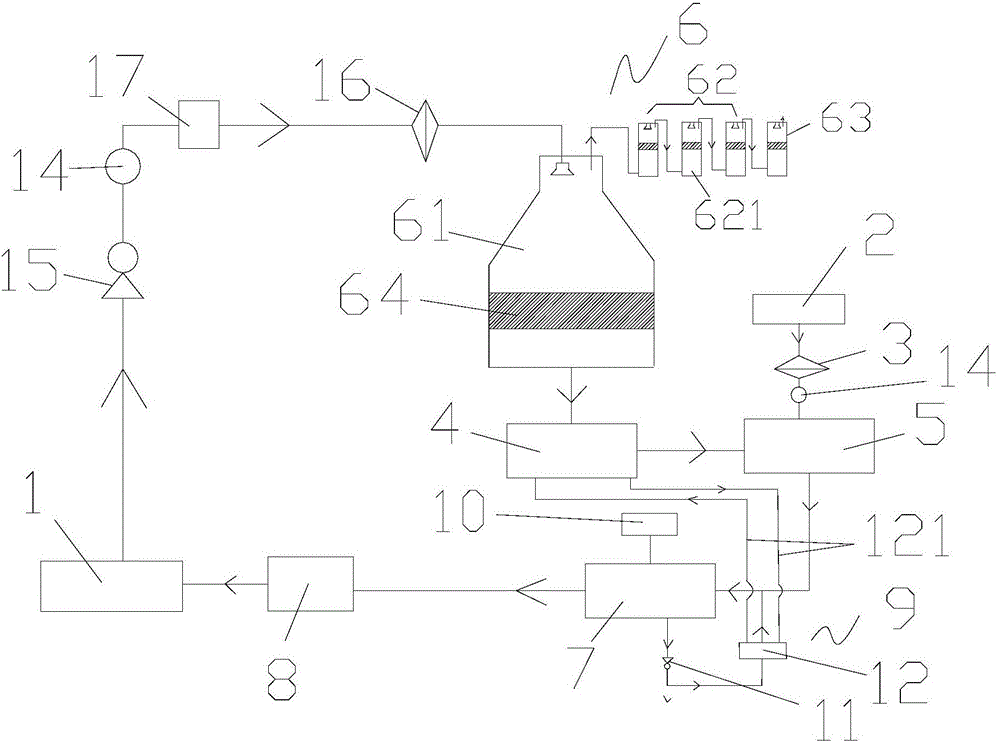

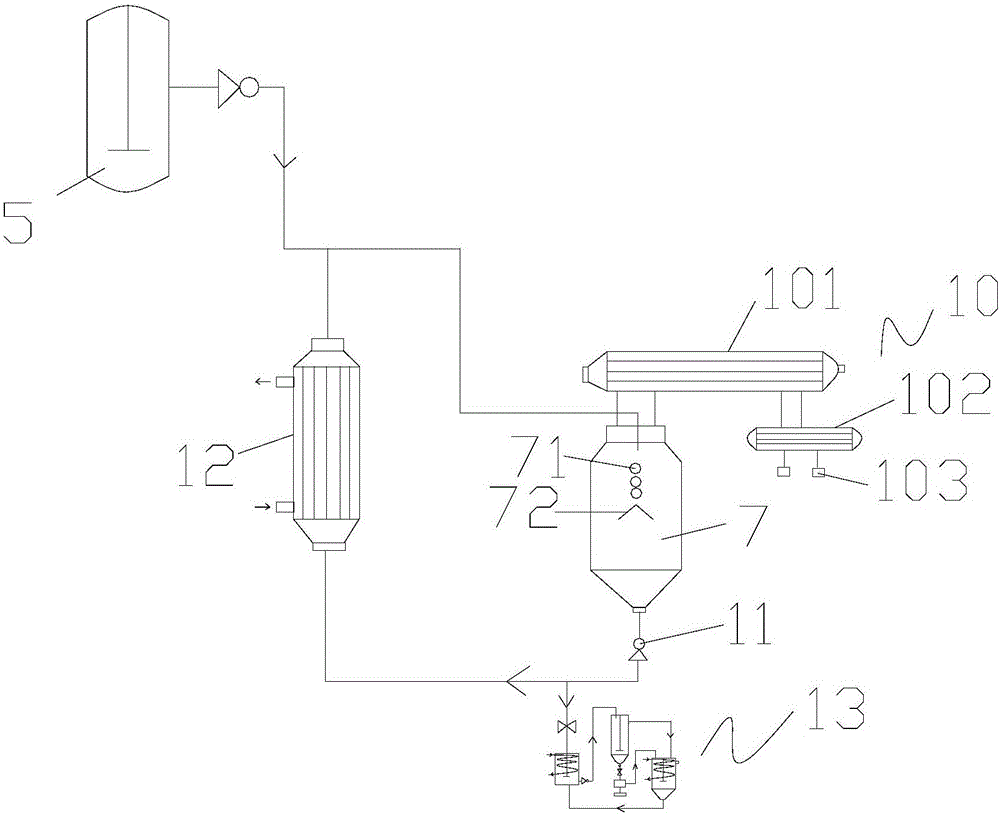

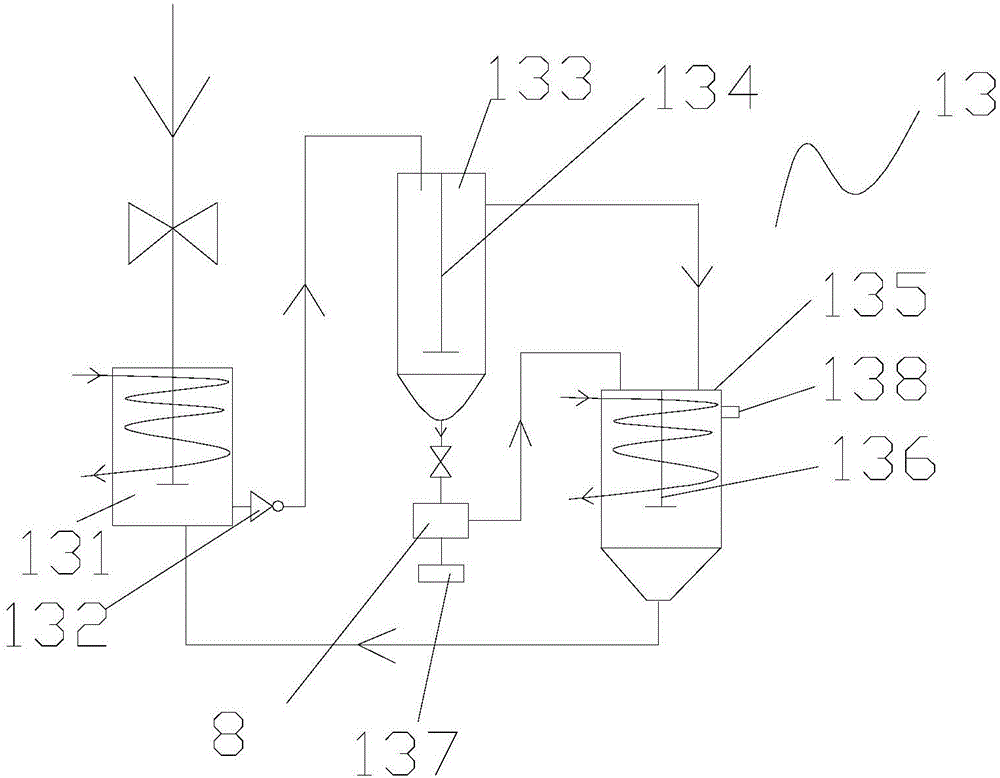

[0027] Such as Figure 1-Figure 3 The production equipment of a kind of potassium chlorate shown comprises alkaline sodium chloride dissolving device 1 and potassium chloride dissolving device 2, and potassium chloride dissolving device 2 is communicated with metathesis reaction equipment 5 by the first filter 3; Alkaline sodium chloride Dissolving device 1 is communicated with electrolytic tank 4, electrolytic tank 4 is communicated with chlorine removal device 6 and metathesis reaction equipment 5, metathesis reaction equipment 5 is communicated with crystallizer 7, crystallizer 7 is communicated with centrifugal device 8, and centrifugal device 8 is communicated with alkaline sodium chloride The dissolving device 1; the crystallizer 7 is connected with a solution concentration device 9; the alkaline sodium chloride dissolving device 1 and the potassium chloride dissolving device 2 are both connected with a flow meter 14.

[0028] Chlorine removal device 6 comprises the spra...

Embodiment 2

[0035] A kind of production method of potassium chlorate, comprises the steps:

[0036] Step 1: Dissolve sodium chloride to form a sodium chloride solution, add NAOH or KOH to adjust the pH value of the sodium chloride solution to 10-11; dissolve potassium chloride to form a potassium chloride solution; add Na to the potassium chloride solution 2 CO 3 and NaOH to remove impurities.

[0037] In this patent, after potassium chloride is dissolved into a homogeneous phase, there is only one solute of KCl and a small amount of calcium and magnesium ions in the solution. After adding Na2CO3 and NaOH, CaCO3 and Mg(OH)2 will be produced and settled. Compared with the removal of impurities by multi-component systems, there are no dangerous substances such as NaCIO3 and KCIO3 and heavy metal salts such as Na2Cr2O7 brought into the salt mud, and only a small amount of KCI in the solid waste is general industrial solid waste, without environmental hazards and troubles in disposal, and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com