An operational mechanical device and its electrical system

A technology of electrical systems and mechanical equipment, applied in the fields of electric energy management, electric vehicles, transportation and packaging, etc., can solve the problems that the electrical system of the main vehicle occupies a large space, the overall space of the main vehicle is tight, and the counterweight is unreasonable, etc., to achieve Lightweight, reduced space and important requirements, the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

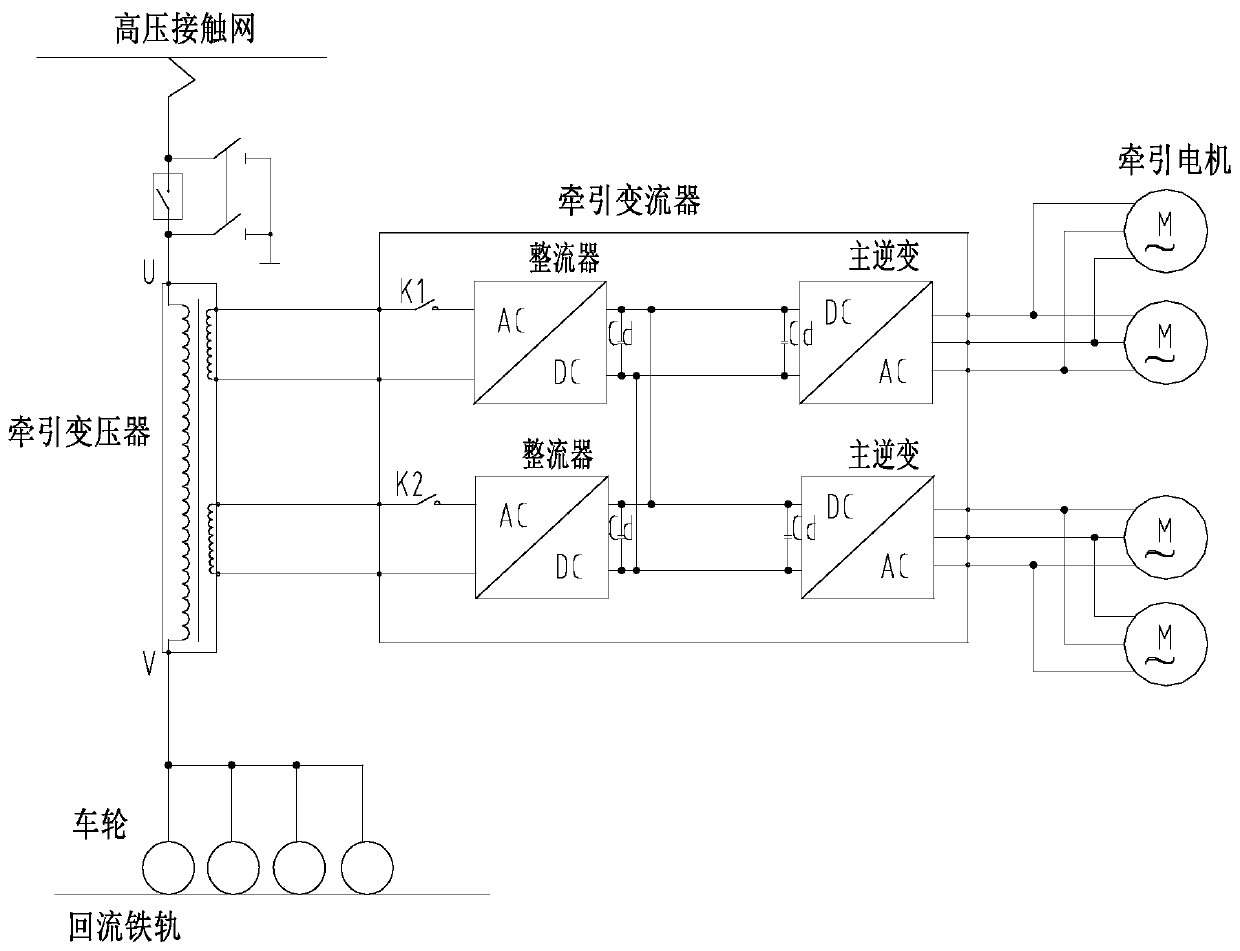

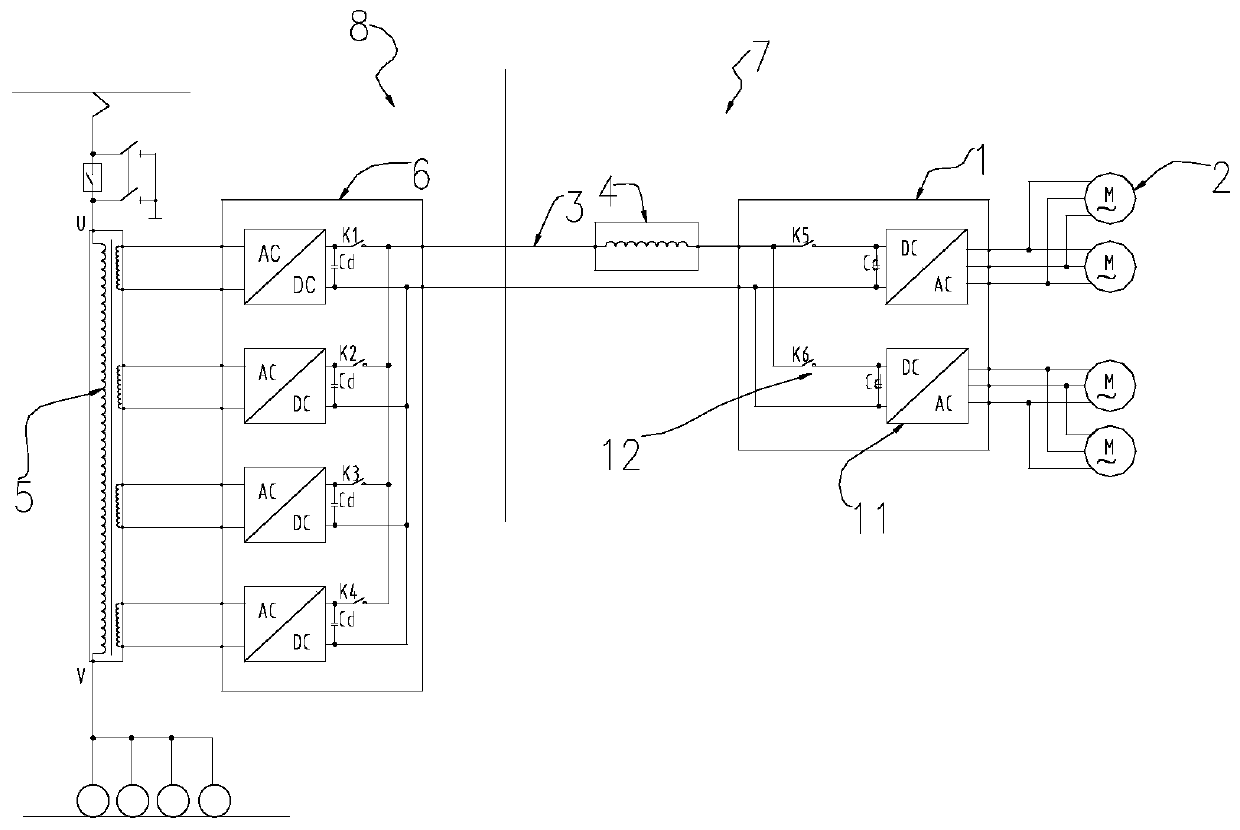

[0025] Please refer to figure 2 , this embodiment provides an electrical system of an operable mechanical device, including a traction inverter 1 and a traction motor 2 . Wherein, the traction inverter 1 obtains DC power from the power supply equipment through the DC bus 3 , and converts the DC power into three-phase AC power to supply to the traction motor 2 .

[0026] Optionally, refer to Figure 7 , four traction motors 2 are connected in parallel at the output end of the traction inverter 1 in this embodiment.

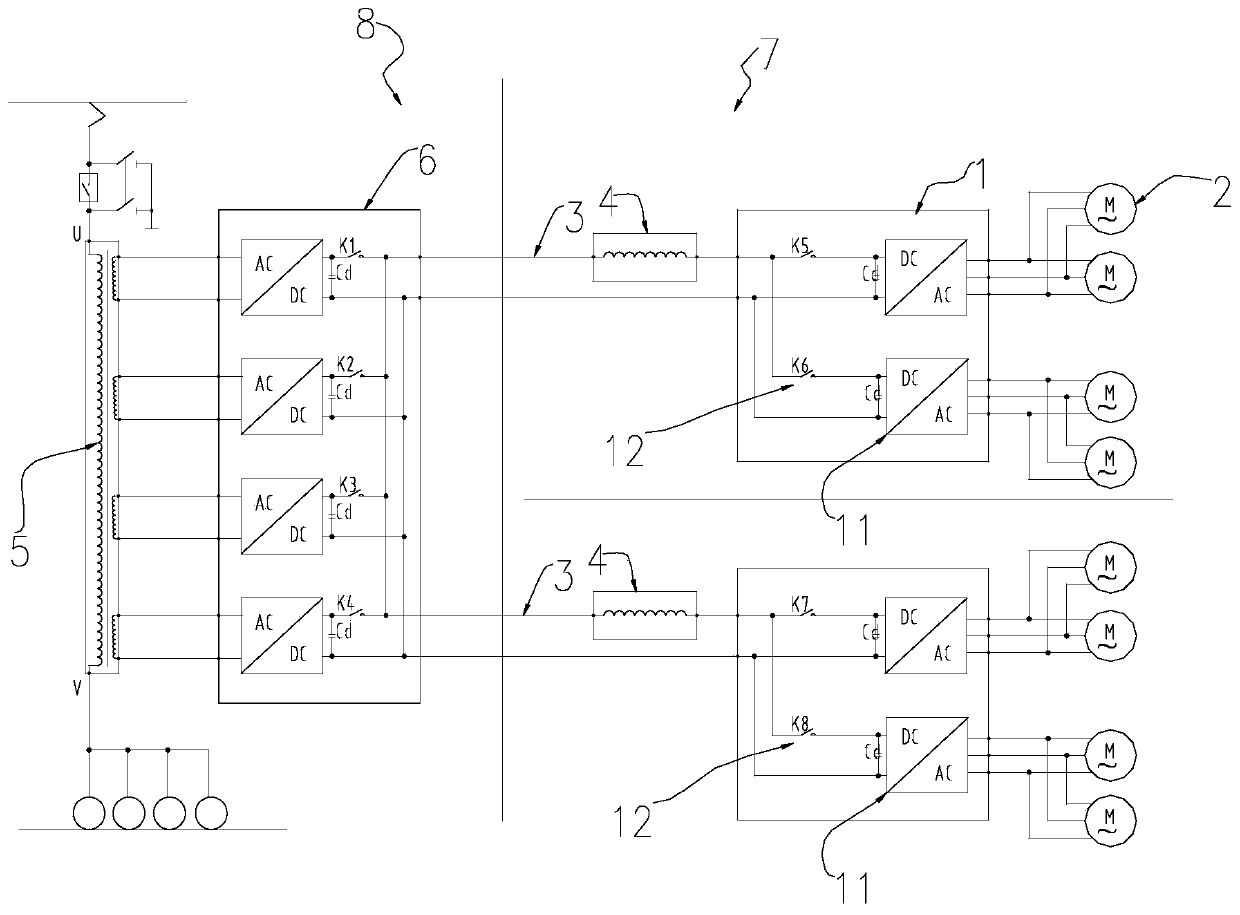

[0027] Optionally, refer to figure 2 , image 3 and Figure 4 , the traction inverter 1 in this embodiment includes two inverter units, and each inverter unit is connected to two parallel traction motors 2 respectively. The number of traction inverter 1 can be one, such as figure 2 , can also be two or more, such as image 3 .

[0028] Optionally, refer to Figure 8 , the traction inverter 1 in this embodiment includes four traction inverter units 11 , ...

Embodiment 2

[0034] Please refer to Figure 2 to Figure 9 In this embodiment, on the basis of Embodiment 1, an inductance device is added on the DC bus 3, and the inductance device is arranged at the current input end of the traction inverter 1, which is used for the current fluctuation on the DC bus 3 to avoid short circuit conditions The fault current under the fault is too large, resulting in damage to electrical equipment. The inductive device is preferably a line reactor 4 .

Embodiment 3

[0036] Please refer to Figure 2 to Figure 9 In this embodiment, on the basis of Embodiment 1 and Embodiment 2, a DC conversion device is added, and the DC conversion device is connected to the power supply device, and is used to convert the unidirectional AC power on the power supply device into DC power, and then transmit it through the DC bus 3 to the traction inverter 1, and then to the traction motor 2. The DC conversion equipment in this embodiment specifically includes a traction transformer 5 and a traction rectifier 6, wherein the traction transformer 5 is connected to the power supply equipment for stepping down the unidirectional AC power provided by the power supply equipment, and the traction rectifier 6 is connected to the traction transformer 5 , which is used to convert the stepped-down unidirectional alternating current into direct current. The DC conversion device in this solution can also be a power electronic transformer 9 .

[0037]The purpose of adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com