Multi-coordinate high-speed parallel robot mechanism

A robot, multi-coordinate technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of limited working space, poor rapidity, and low rigidity, and achieve the effect of simple and compact structure and improved working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

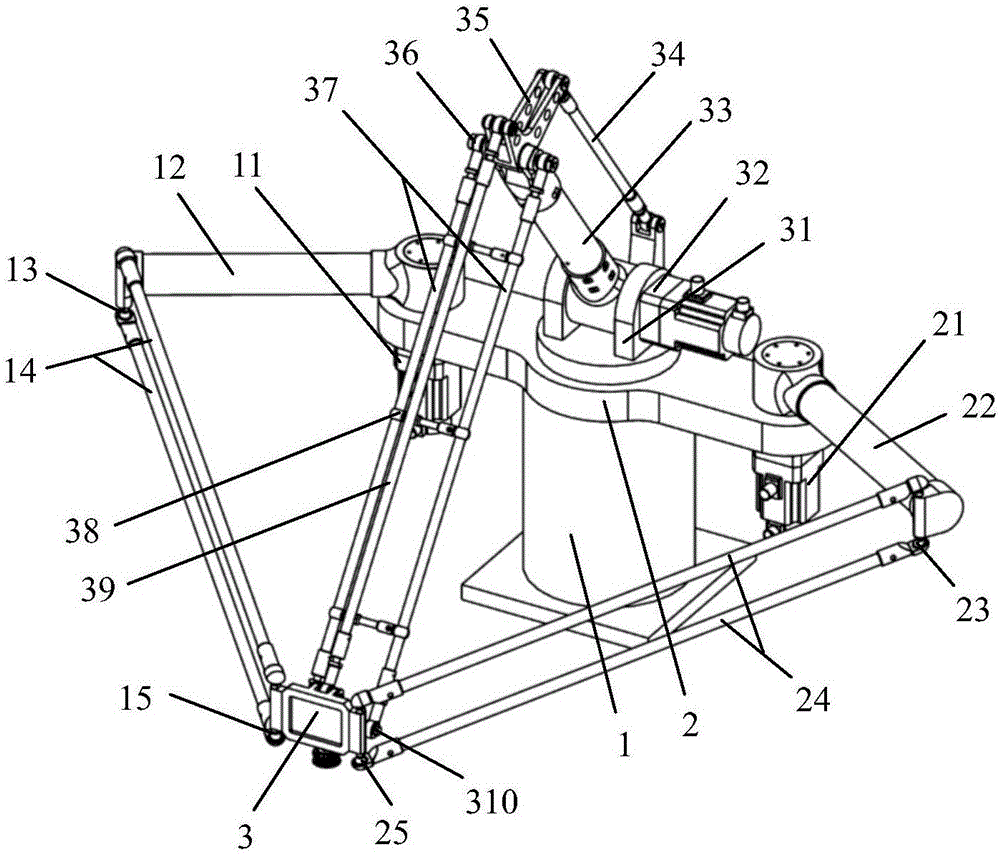

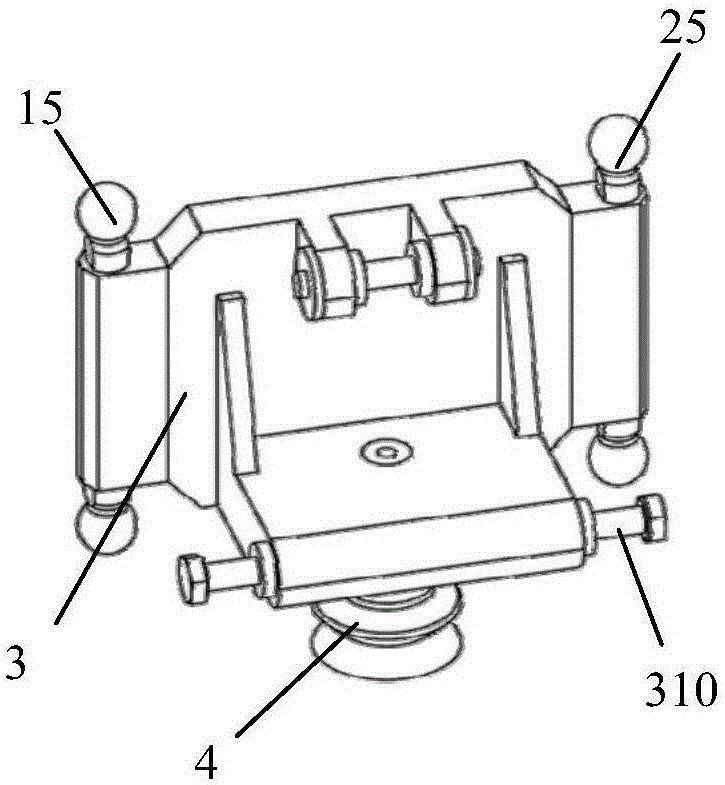

[0041] combined with Figure 1-2 , a multi-coordinate high-speed parallel robot mechanism, including a fixed frame 1, a supporting platform 2, a moving platform, and a first branch chain, a second branch chain and a third branch chain connecting the support platform 2 and the moving platform,

[0042] The support platform 2 is fixedly connected to the fixed frame 1;

[0043] The first branch chain and the second branch chain structure are identical, and are distributed on both sides of the third branch chain;

[0044] The first branch chain includes a first driving device 11, a first near frame rod 12, a first upper connecting shaft 13, two parallel and equal long first far frame rods 14 and a first lower connecting shaft 15; The first driving device 11 is fixedly connected with the support platform 2, and one end of the first frame rod 12 is rotationally connected with the support platform 2, and is fixedly connected with the driving end of the first drive device 11, and the...

Embodiment 2

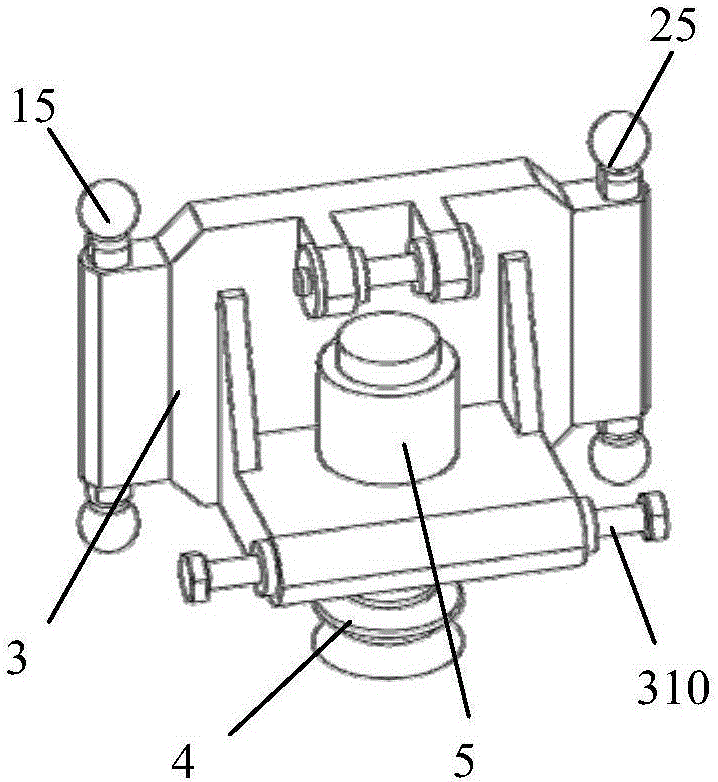

[0050] combined with figure 1 and 3 The difference between implementation 2 and embodiment 1 is that, on the basis of example 1, an end effector 4 is rotatably connected to the moving platform, and an end effector driving device 5 is fixedly connected, and the end effector 4 and The driving end of the end effector driving device 5 is fixedly connected. Embodiment 2 is a three-level one-rotation three-degree-of-freedom high-speed parallel robot mechanism.

Embodiment 3

[0052] combined with Figure 4-6 , the difference between Example 3 and Example 1 is that

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com