A method for preparing cds/mos2 composite hollow square photocatalyst

A photocatalyst and block technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., to achieve the effect of complete crystallization and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1CdS / MoS 2 Preparation of composite photocatalyst

[0014] Select 300mg of cadmium carbonate, sodium molybdate and 500mg of thiourea. The amount of sodium molybdate added is 1:0:4, 1:0.15:4, 1:0.3:4, 1:0.6:4 according to the ratio of the amount of substance. , 1:1.2:4, 1:1.4:4 were added, and 6 groups of samples were dissolved in 35ml of deionized water, magnetically stirred, and hydrothermally reacted at 220 degrees Celsius for 24 hours. After the reaction, the resulting products were sequentially deionized Wash with water and ethanol, filter, and place in a constant temperature drying oven at 60 degrees Celsius to dry.

Embodiment 2

[0015] Example 2CdS / MoS 2 Characterization and Analysis of Heterojunction Composite Photocatalyst

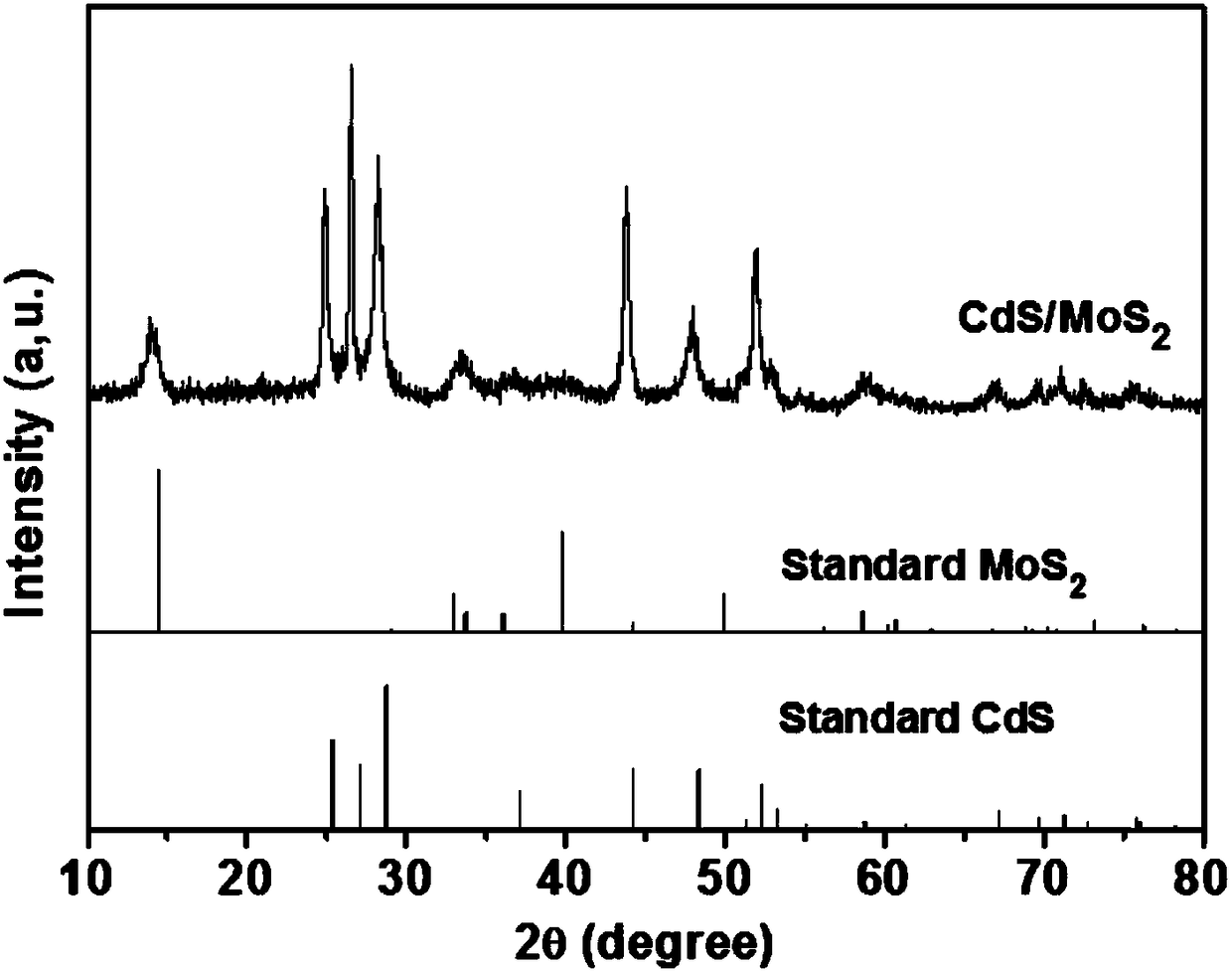

[0016] Such as figure 1 As shown, it can be seen from the figure that there are CdS and MoS 2 Diffraction peaks and no other impurity phases indicate that the purity of the composite structure we obtained is high.

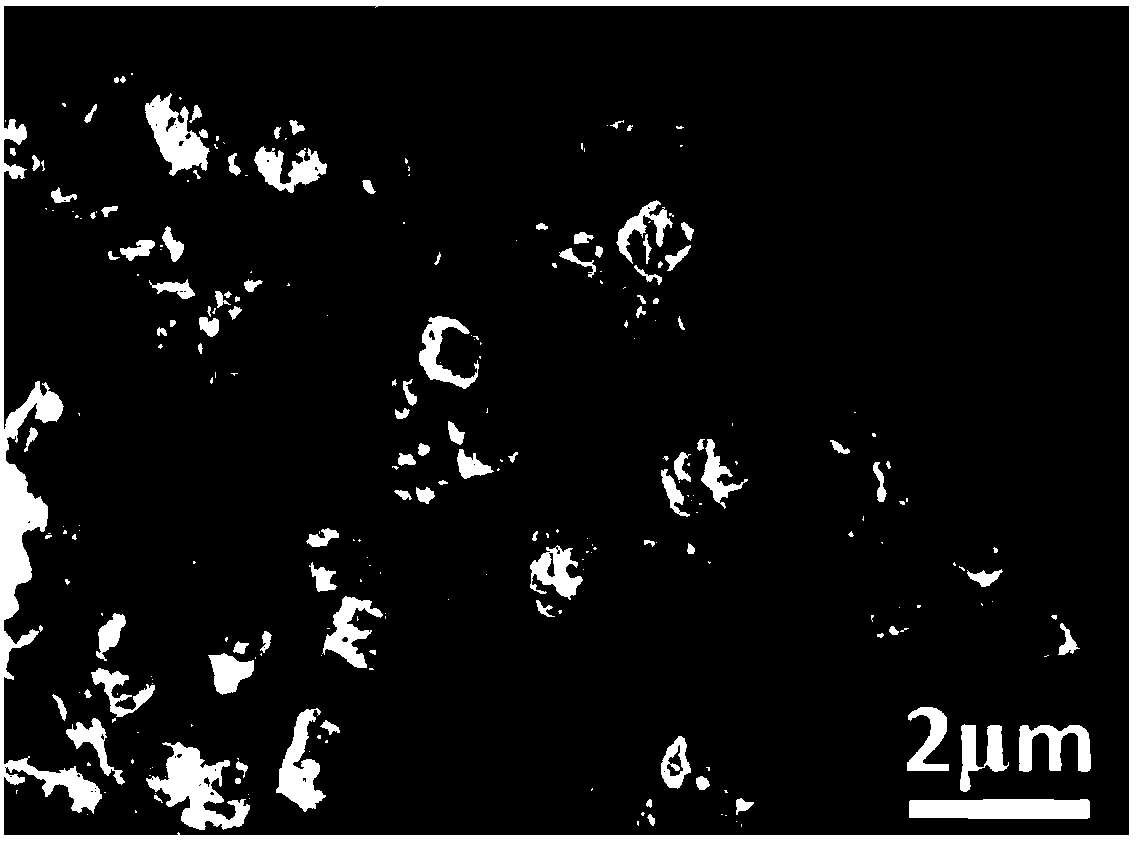

[0017] Such as figure 2 As shown, the uniformly distributed hollow square structure can be seen from the figure.

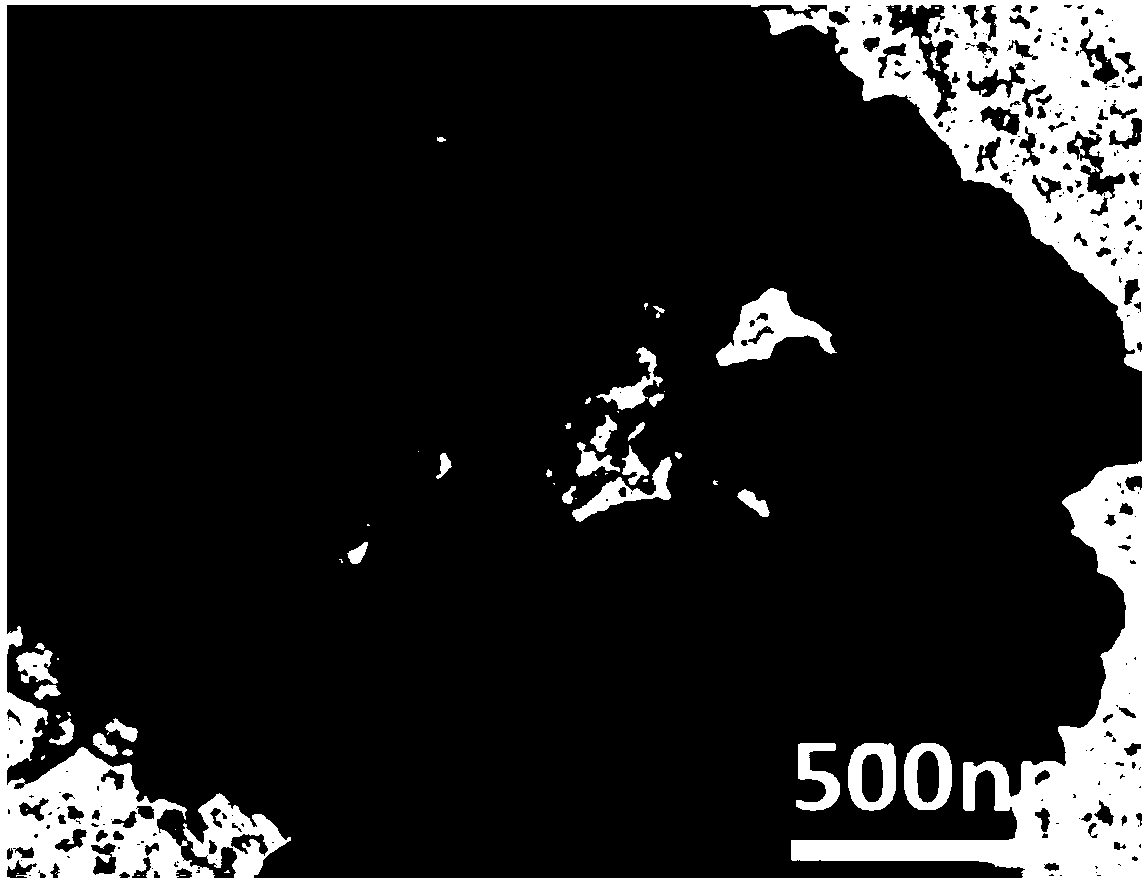

[0018] Such as image 3 As shown, you can see MoS 2 The nanosheets were successfully coated on the surface of the CdS hollow square to form a heterogeneous structure.

[0019] Such as Figure 4 As shown, the CdS / MoS can be clearly seen in the figure 2 The composite photocatalyst has excellent photocatalytic hydrogen production performance. When the ratio of cadmium carbonate, sodium molybdate and thiourea is 1:1.2:4, the photocatalytic hydrogen production efficiency is the highest.

Embodiment 3

[0020] Example 3CdS / MoS 2 Visible light catalytic activity experiment of heterojunction composite photocatalyst

[0021] (1) Weigh CdS / MoS 2 100mg of composite photocatalyst was placed in a photocatalytic hydrogen production reactor, 100ml of water was added, and 10ml of lactic acid was stirred for 20 minutes.

[0022] (2) The amount of hydrogen generated is measured by gas chromatography every 1 hour.

[0023] (3) by Figure 4 It can be seen that the prepared composite photocatalyst has excellent visible light catalytic activity, and the composite sample has higher hydrogen production performance than pure CdS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com