Spherical concentrator capable of being uniformly heated

A technology of uniform heating and concentration tank, which is applied in the direction of evaporator accessories, evaporation, chemical instruments and methods, etc. It can solve the problems of small capacity of concentration tank and uneven heating, so as to increase the absorption rate, enhance the uniformity of heating and save energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

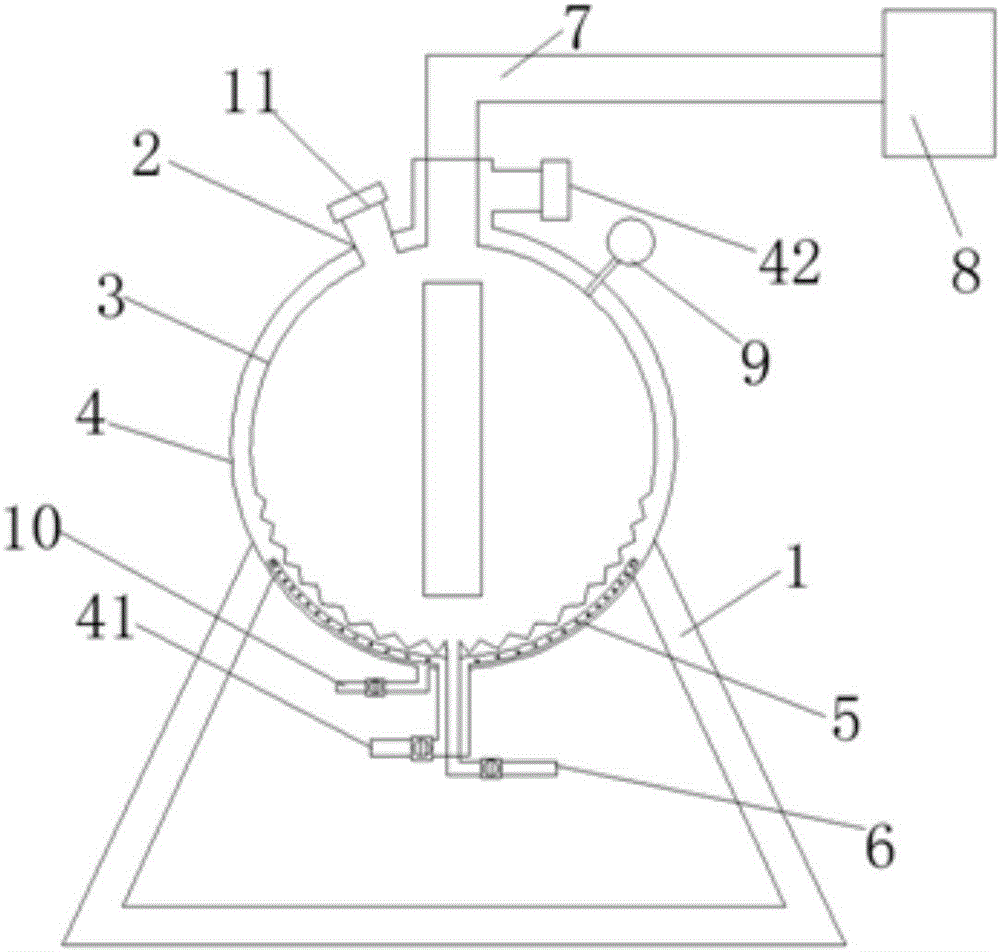

[0016] like figure 1 A uniformly heated spherical concentration tank shown includes a spherical tank body 2 fixed on a support 1; the spherical tank body 2 includes an inner tank 3 and an outer tank 4, and the inner tank 3 and the outer tank 4 Form a steam chamber; the bottom of the outer tank 4 is provided with a steam inlet 41, and the top of the outer tank 4 is provided with a steam outlet 42, and a plurality of steam dispersion pipes 5 are connected on the steam outlet 42; the steam dispersion pipe 5 is arranged in the steam cavity; steam holes are uniformly distributed on the steam dispersion pipe 5; the plurality of steam dispersion pipes 5 are evenly distributed with the vertical center axis of the spherical tank body (2) as the axis; the inner tank The bottom end of 3 is provided with a discharge pipe 6, and the discharge pipe 6 leads to the outside of the spherical concentration tank through the steam outlet 42, and the upper end of the inner tank 3 is provided with a...

Embodiment 2

[0019] This embodiment has been further improved on the basis of embodiment 1, as figure 1 A uniformly heated spherical concentration tank is shown; a pressure gauge 9 is also installed on the spherical tank body 2, and a feed port 11 is provided on the inner tank 3; the feed port 11 passes through the outer tank 4 leads to the outside of the spherical tank body 2.

Embodiment 3

[0021] This embodiment has been further improved on the basis of embodiment 1, as figure 1 Shown is a uniformly heated spherical concentration tank; the bottom of the outer tank 4 of the spherical tank body 2 is provided with a condensed water outlet 10, which can discharge the cooling water condensed in the steam chamber to ensure the normal operation of the concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com