Vacuum lock system and processing method of substrates by using same

A technology of vacuum processing and vacuum lock, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve the problems of vacuum robot burden, work efficiency and output limitation, etc., so as to reduce the conveying pressure, improve work efficiency, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

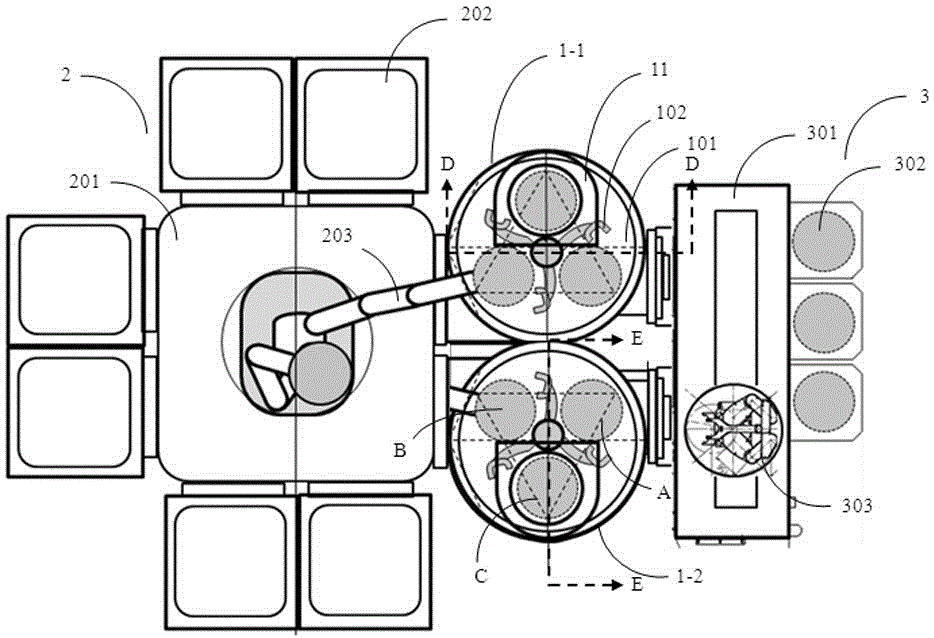

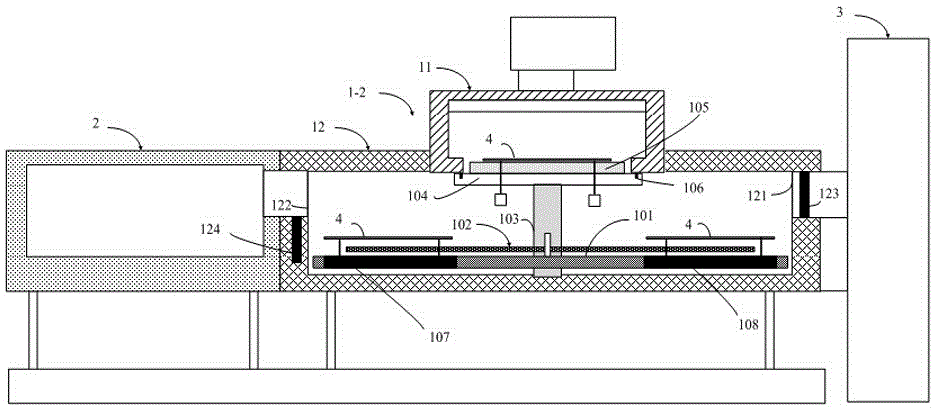

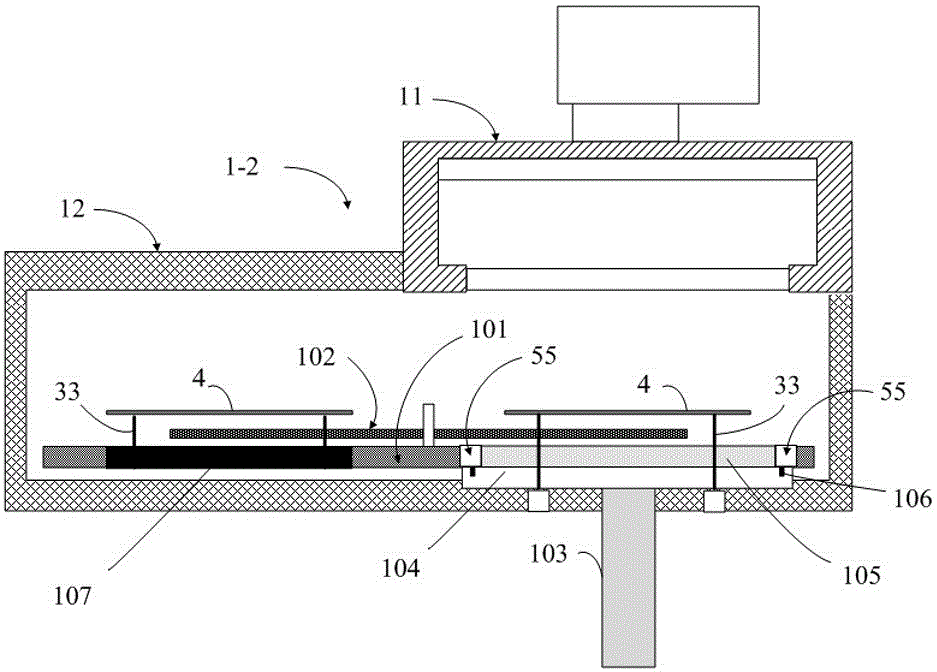

[0037] based on the following Figure 1 to Figure 5 , specifically explain the preferred embodiment of the present invention.

[0038] Such as Figure 1 ~ Figure 4 As shown, a vacuum lock system provided by the present invention includes a chamber main body, a substrate transfer support assembly and a substrate lifting assembly disposed in the chamber main body.

[0039] The chamber body includes a processing chamber 11 and a substrate transfer chamber 12 , and the processing chamber 11 is vertically stacked on the upper part of the substrate transfer chamber 12 .

[0040] The bottom of the processing chamber 11 has an opening communicating with the substrate transfer chamber 12, and the processing chamber 11 is used to perform plasma processing on the substrate 4 placed therein, for example, it may be removed from the surface of the substrate 4 The photoresist plasma treatment chamber for removing photoresist may also be other plasma treatment chambers such as removal of et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com