Heat pump smoke waste heat recycling system of gas engine

A waste heat recovery system and flue gas waste heat technology, applied in the field of energy saving, can solve problems such as increasing high-grade energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

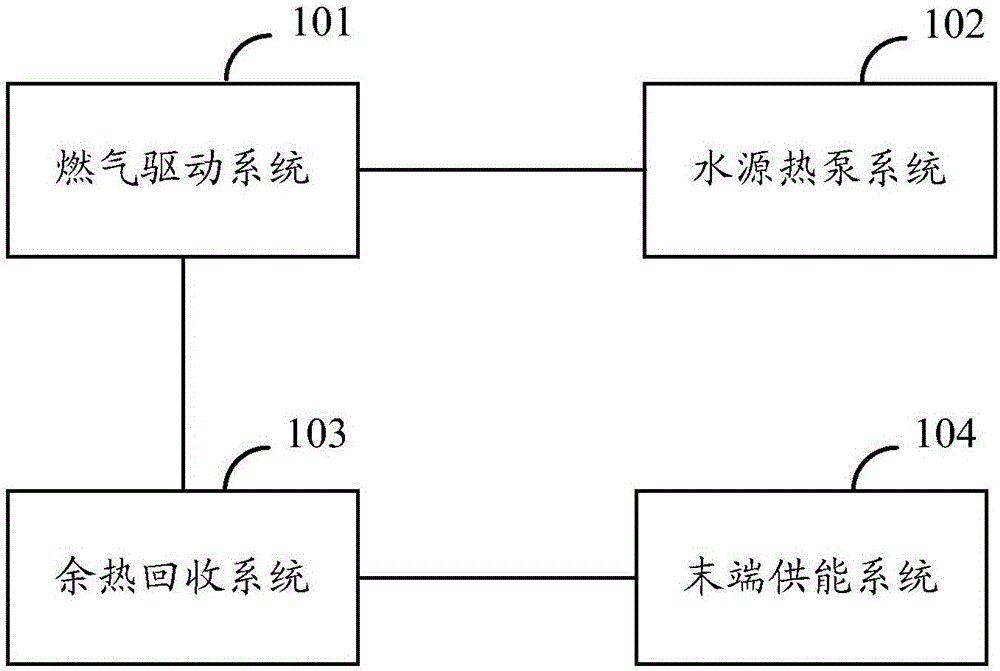

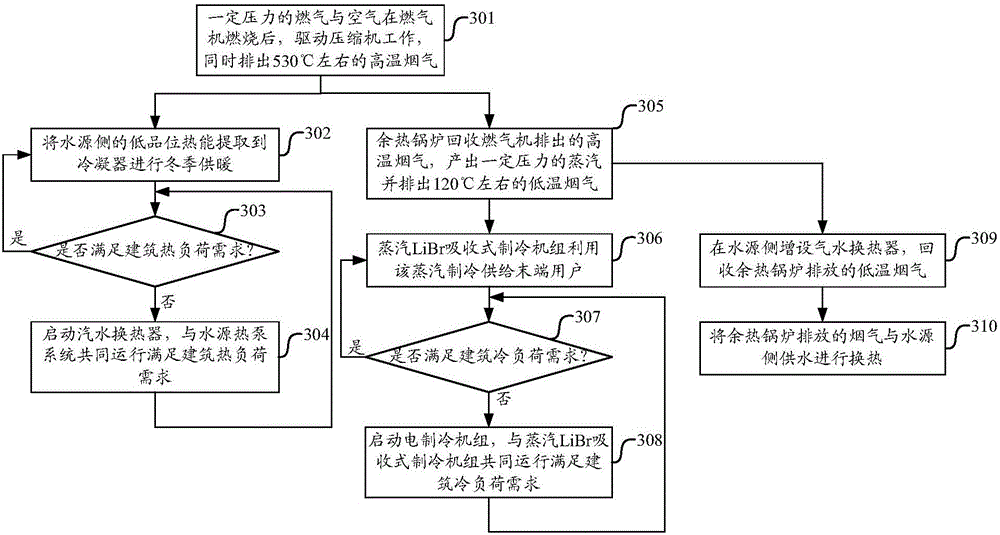

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0026] The inventor noticed during the invention that:

[0027] A gas engine heat pump is a compression heat pump device driven by a gas (usually natural gas) engine, which uses natural gas as energy input to provide cooling or heating to end users. The gas engine heat pump has the advantages of high utilization rate of primary energy, strong low temperature adaptability, and good partial load performance.

[0028] For large public buildings with both cooling load and heating load demand, if traditional electric refrigerators are used for cooling, the consumption of high-grade energy will be increased. In the gas engine heat pump system, the waste heat of the gas engine is large and the taste is high, and the waste heat of the gas engine can be used for cooling.

[0029] In addition, the gas engine heat pump is directly driven by the gas engine. Excep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com