Hearth observation device

An observation device and furnace technology, which are applied to the safety device, combustion method, combustion chamber and other directions of the combustion chamber, can solve the problems of burns, unfavorable recording and analysis data, and inability to realize the shooting of the furnace flame, and achieve the effect of being convenient to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

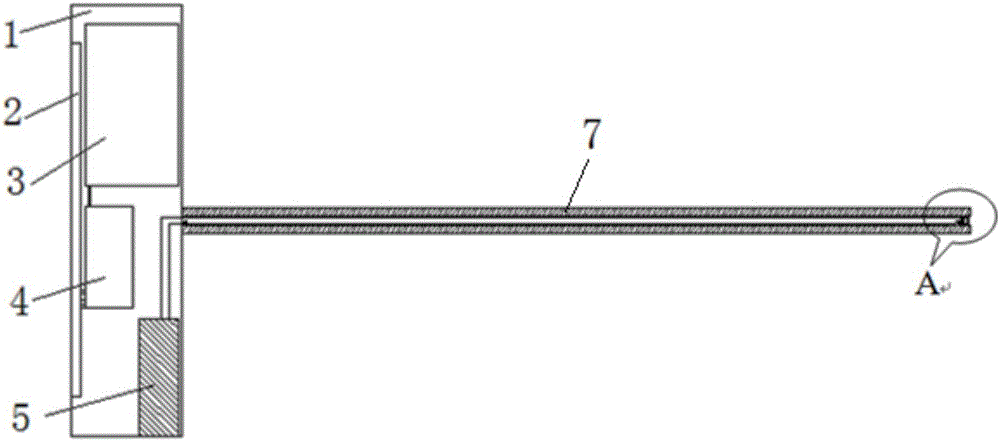

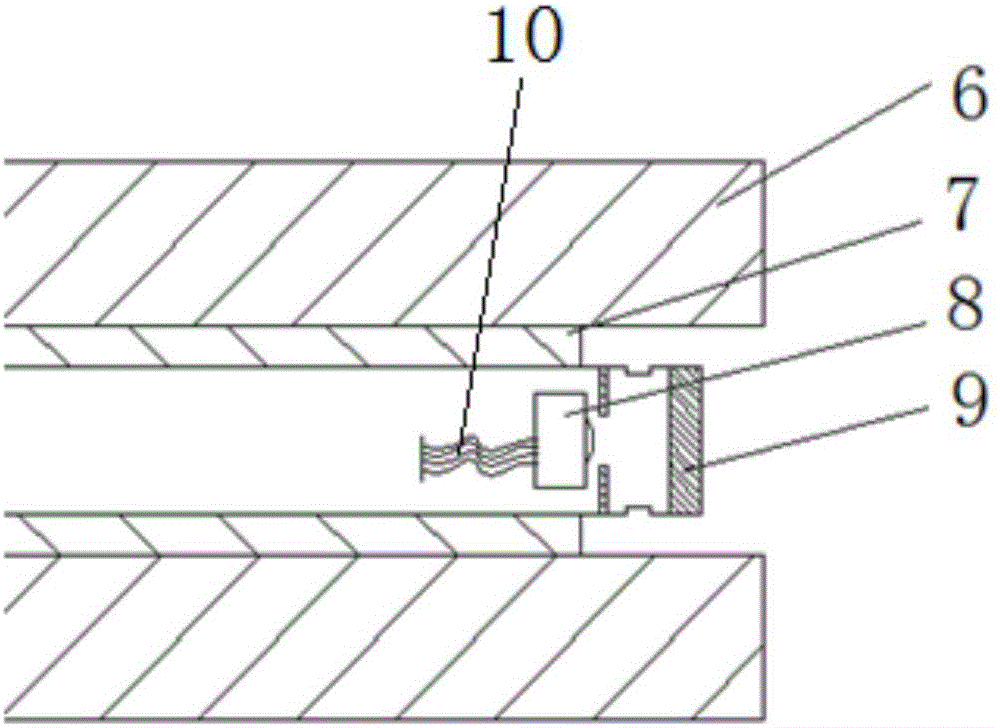

[0031] figure 1 A schematic structural view of an embodiment of the furnace observation device according to the present invention is shown. combine figure 2 As shown, the device includes a camera body 1 and a camera 8 electrically connected to the camera body 1 . Wherein, the camera body 1 is connected to a flexible tube 7 that can be bent and shaped, and the camera head 8 is fixed to the flexible tube 7 .

[0032] In the furnace observation device of the present invention, the camera 8 is fixed in the flexible pipe 7 that can be bent and shaped, and the flexible pipe 7 is used as a support for the camera 8 on the one hand, and the camera 8 can be observed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com