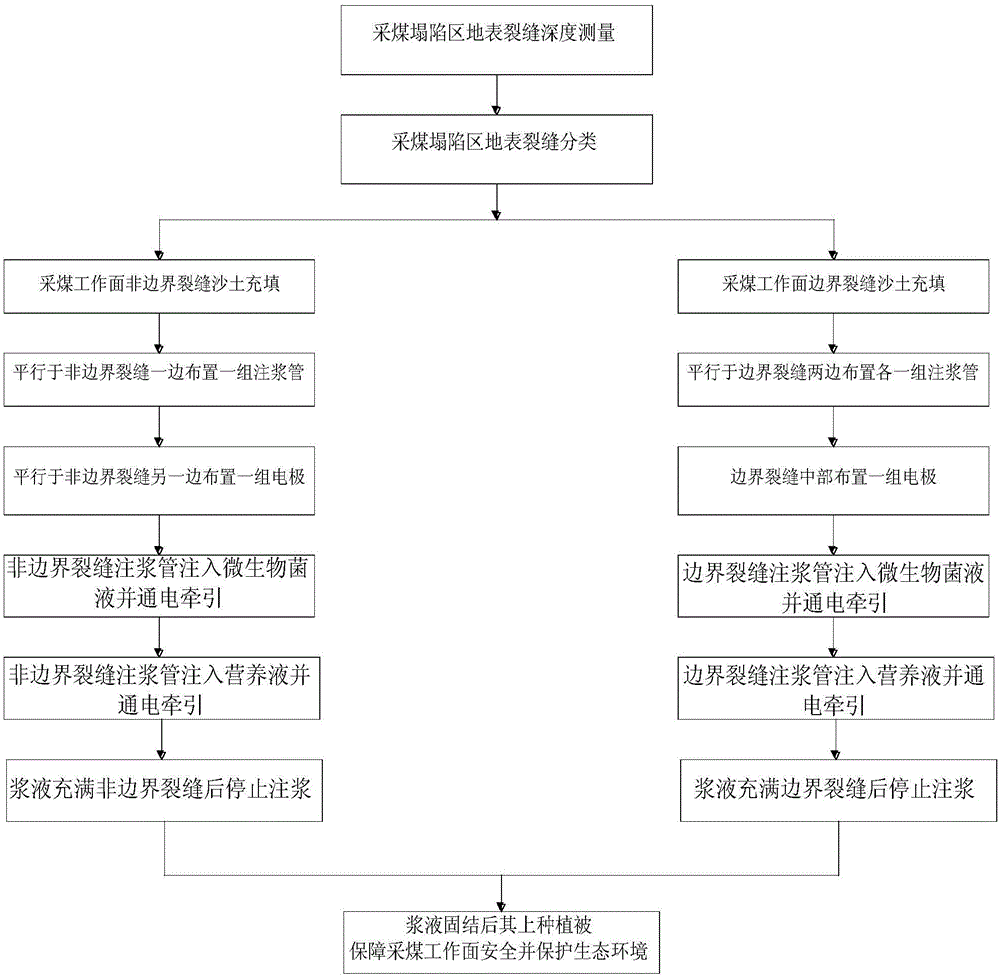

Device and method for repairing ground cracks of coal mining loess subsidence area

A technology for surface cracks and subsidence areas, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of environmental impact and high cost, achieve good effects, ensure restoration effects, and prevent soil loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Loess Plateau 1 Coal Mining 2 -2 No. 2 coal, one of the No. 2203 working faces was mined with a large number of surface cracks, which were repaired using the following steps:

[0071] Step 1: Observing the depth of all the surface cracks formed in the No. 2203 coal mining face, the depth of the surface cracks is 0.1 meters to 2.8 meters.

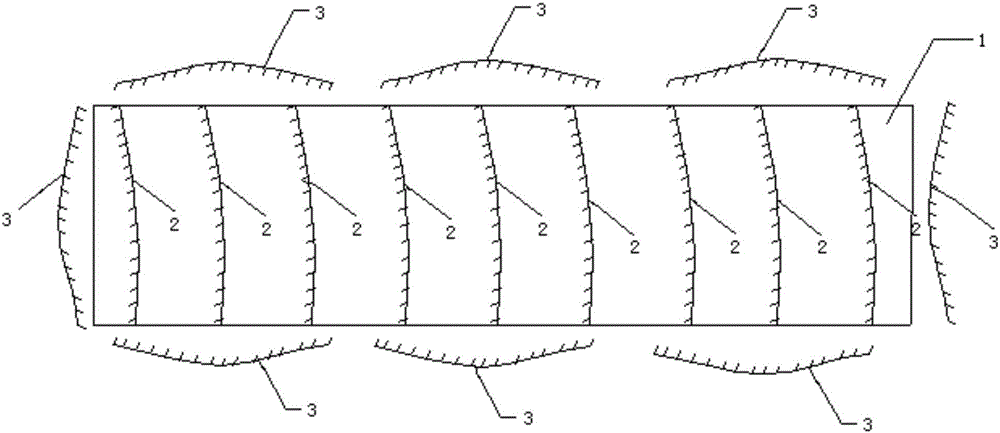

[0072] Step 2: Divide the surface cracks into two categories, one is the boundary crack 3, the coal mining face 1 two lanes, the cutting hole and the harvest line are vertically projected to the ground fissures beyond the ground, there are 11 cracks, and the remaining cracks For non-boundary cracks 2, there are 38;

[0073] Step 3: Use different grouting methods for non-boundary crack 2 and boundary crack 3.

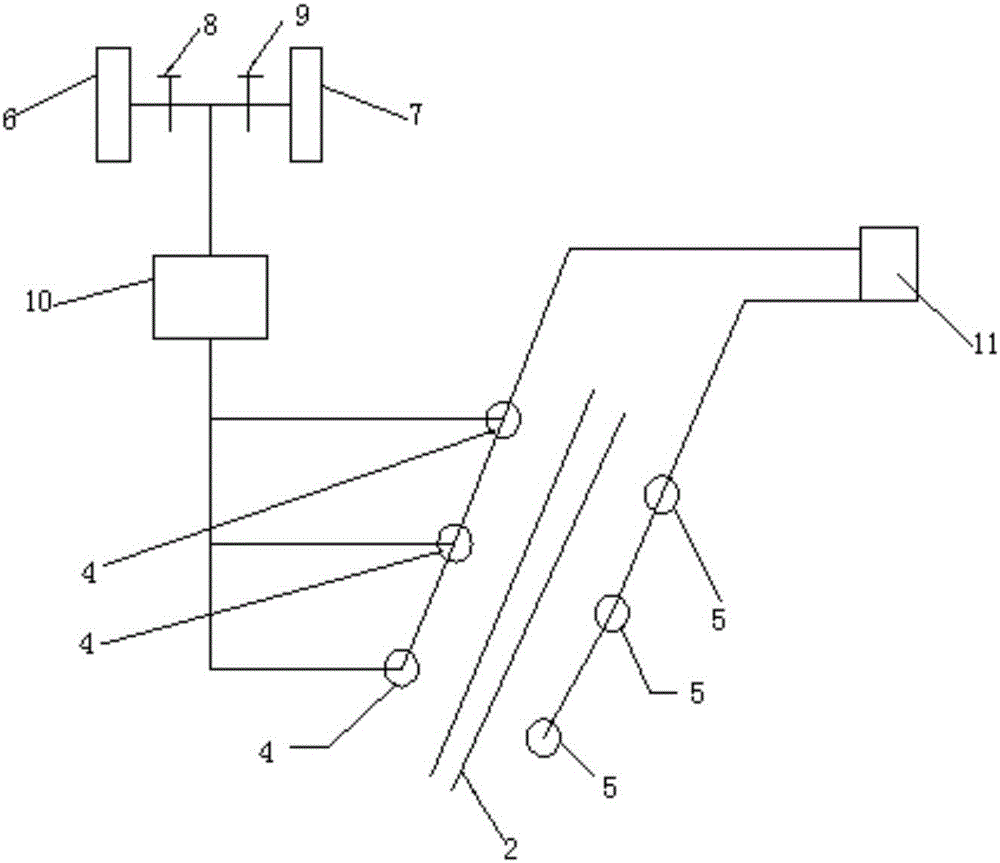

[0074] For non-boundary crack 2, use the following steps for grouting:

[0075] First, the non-boundary crack 2 is filled with sand, and the sand is taken from the local material, the particle size is 0.05-0.25mm, the clay co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com